Your Guide to Dewpoint Temperature

July 27, 2023Your Guide to Dewpoint Temperature

Dewpoint temperature (Td) is the temperature at which water vapor in the air becomes saturated and starts to condense. It forms moisture or “dew” on the surface of material that will need to be logged ahead of the coatings process.

However, it doesn’t need to be raining for moisture to form on the surface of your material. A bottle removed from a refrigerator and brought into warm air quickly forms condensation and creates moisture on the external surface.

This is where environmental factors come into play. Climatic conditions have a huge influence on the dewpoint temperature so if you’re planning to carry out any coating projects, we suggest you keep reading.

The Cost of Getting the Dewpoint Temperature Wrong

Inaccurately measuring dewpoint temperature can mean that you apply paint to a surface at the incorrect temperature which can lead to:

- Blistering

- Mud patches

- Craters

- Dry Spray

- Pinholing

Not only do these defects look visually unappealing, but they can also put people in danger if they’re not quickly managed or rectified.

So how do you accurately work out the dewpoint temperature to avoid these issues?

How to Calculate Dewpoint Temperature

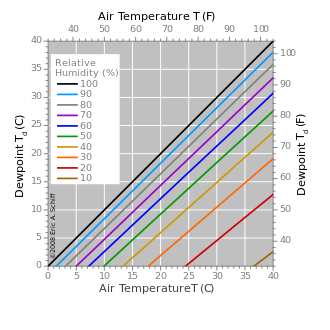

To calculate the dewpoint temperature, you first need to measure the air temperature (Ta) and the relative humidity (RH) of the air. We’ve attached a dewpoint temperature chart to help you.

To save you doing all the calculations and heading back to the office to log your findings, the Elcometer 319 Dewpoint Meter can withstand all climatic conditions to provide you with accurate, remote readings of:

- Dewpoint temperature (Td)

- Relative Humidity (RH)

- Air Temperature (Ta)

- Delta (Δ)

- Surface Temperature (Ts)

- Wet bulb temperature (Twb)

- Dry bulb temperature (Tdb)

Alternatively, you can also use the following formula to calculate dewpoint from temperature and relative humidity:

Td = Ta - ( 100-RH/5)

So, if you have an air temperature of 20°C and a relative humidity of 50%, your dewpoint temperature is 10°C. If you want to find out more about how to measure Ta, RH and Td, you can read about it in our Climatic Testing Guide.

Now you can convert dewpoint and Rh to temperature and vice versa, let’s take a look at how surface temperature relates to it.

The Relationship Between Dewpoint Temperature and Surface Temperature

It might seem like common sense, but you’d be surprised on how many projects overlook the surface temperature at the start of the coating process. As you can imagine, getting the surface temperature wrong or not taking it into account at all has resulted in poor finishes and a lot of reworks.

The surface temperature tells us the risk of moisture formation on any given material that’s due to be prepped and coated and this varies based on:

- The time of day/night

- The material itself

- The conditions the material is kept at

- What the material is used for.

A perfect example of changes in surface temperature are wind turbines that are primarily made of steel. At night, steel work emanates heat and is cooled below air temperature but during the day, the steel turbines will absorb the heat and usually becomes warmer than the air temperature.

The Minimum Surface Temperature

In line with ASTM D3276, “Standard Guide for Painting Inspectors (Metal Substrates),” the minimum surface temperature (Ts) for coating application is usually 40°F (5°C). For “cold-curing” one or two component systems, it may be as low as 0°F (-18°C) or 50°F (10°C) for conventional two-component systems.

The Maximum Surface Temperature

The maximum surface temperature for coating application is 125ºF (50ºC) unless clearly specified otherwise. A surface that’s too hot for coating can cause the coating solvents to evaporate so fast making the application process difficult and increasing the risk of blistering and creating a porous film.

To simplify the surface temperature calculation and recording process, the Elcometer 319 Dewpoint Meter features a magnetic probe that instantly provides you with your surface temperature and allows you to log it remotely.

Equipment Used to Measure Dewpoint Temperature

Whirling & Sling Hygrometers

These instruments are designed to determine the dewpoint and relative humidity at any given time.

Available in Celsius scale only, the Elcometer 116A Whirling Hygrometer is designed to measure the ambient Rh from which the dewpoint temperature can be calculated.

The Elcometer 116C Sling Hygrometer is a convenient, self-contained instrument with an inbuilt slide rule to calculate the relative humidity and dewpoint. It has spirit filled thermometers available in °C and °F.

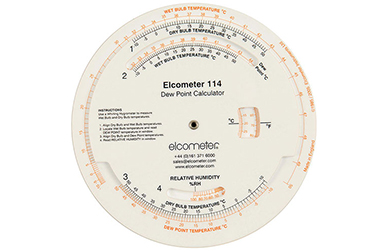

A guide for relative humidity determination is supplied with each instrument and the dewpoint can accurately be obtained using the Elcometer 114 Dewpoint Calculator.

Elcometer 114 Dewpoint Calculator

This provides accurate values of dewpoint and relative humidity from the wet and dry bulb temperatures measured by a Whirling or Sling Hygrometer.

Elcometer 319 Dewpoint Meter

The versatile Elcometer 319 Dewpoint Meter is designed to measure and record all relevant climatic parameters required to determine whether the conditions are suitable for painting. This Meter meets requirements of ISO 8502 Standard and readings are switchable between Celsius and Fahrenheit.

Elcometer 308 & 309

The Elcometer 308 Hygrometer and the Elcometer 309 Digital Delta T Hygrometer have been specifically designed for use in very hot climates where the surface temperature of a substrate can exceed the paint manufacturer's recommended limits for successful painting.

How Elcometer Can Help with Your Dewpoint Testing

Here at Elcometer, we proudly uphold the title of being a world leader in the design, manufacture and supply of inspection equipment to the coating, concrete and NDT industry.

With over 70 years’ experience, we integrate quality into every aspect of all of our products – and our dewpoint testing equipment is by no means an exception.

To measure the dewpoint temperature of your materials with ease and achieve a long-lasting, durable, and quality coating finish, simply browse our climate, dewpoint and relative humidity products.

Alternatively, you can get in touch with an Elcometer office or distributor for advice or to discuss technical queries by using the contact information on our website.