Elcometer 99 Adhesive Tape

- Protective Coatings

- Industrial Finishing

Used as part of the cross hatch adhesion test, the Elcometer 99 Adhesive Tape is used to remove loose particles of paint from a lattice pattern.

- Summary

-

Summary

-

Designed to be used after a cross-cut (cross hatch) adhesion test has be undertaken, the Elcometer 99 Adhesive Tape can be used to remove any loose paint particles from the lattice pattern.

This allows the inspector to determine the degree of coating removal to the relevent standard being used (ISO 2409 or ASTM D 3359), in accordance with the chart provided.

The Elcometer 99 Adhesive Tape can be used with either:

Elcometer 107 Cross Hatch Cutter

Elcometer 1542 Cross Hatch Adhesion Tester

-

- Key Features

-

Key Features

Elcometer 99 Adhesive Tape

How to use the Elcometer 99 Adhesive Tape

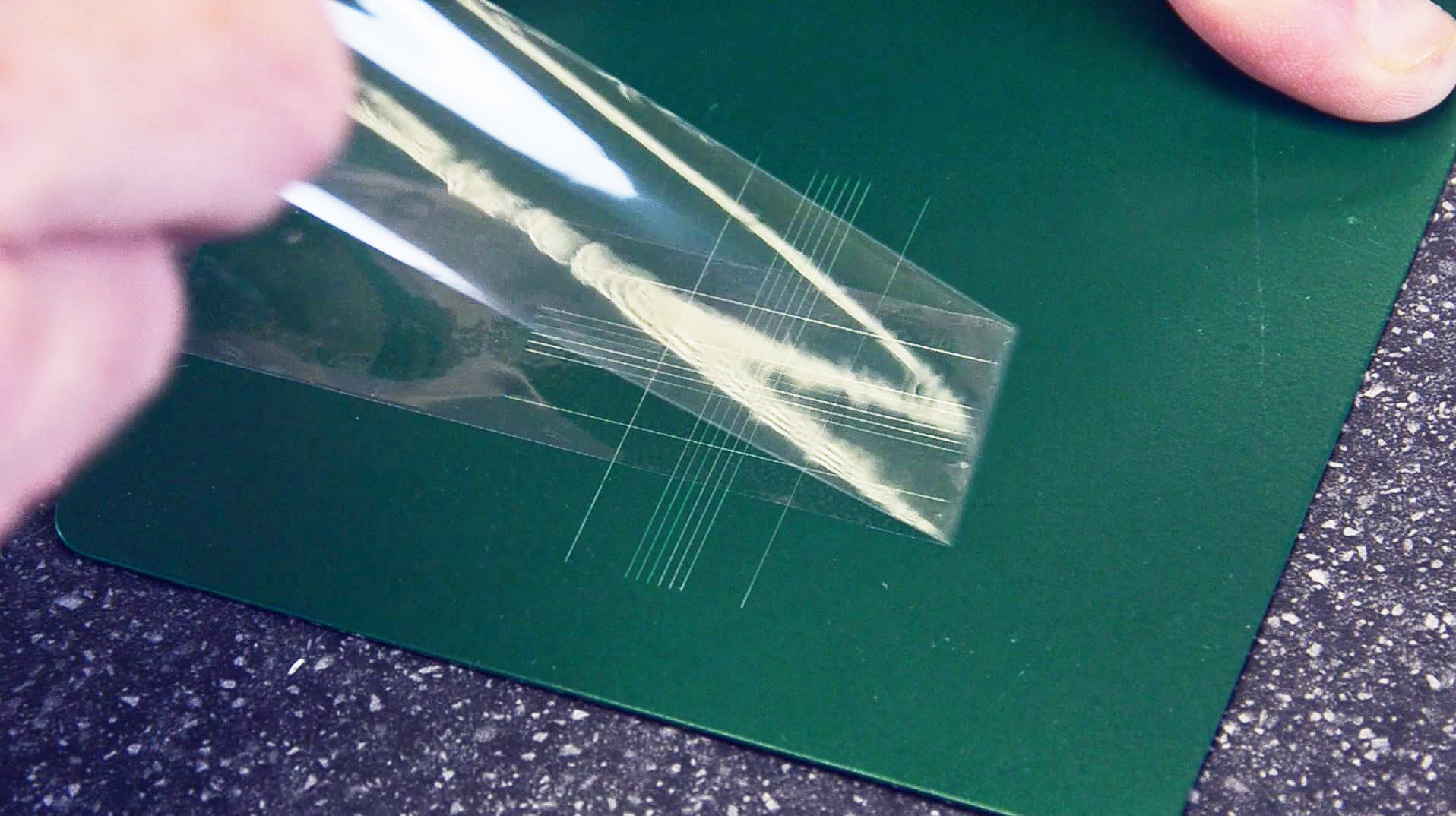

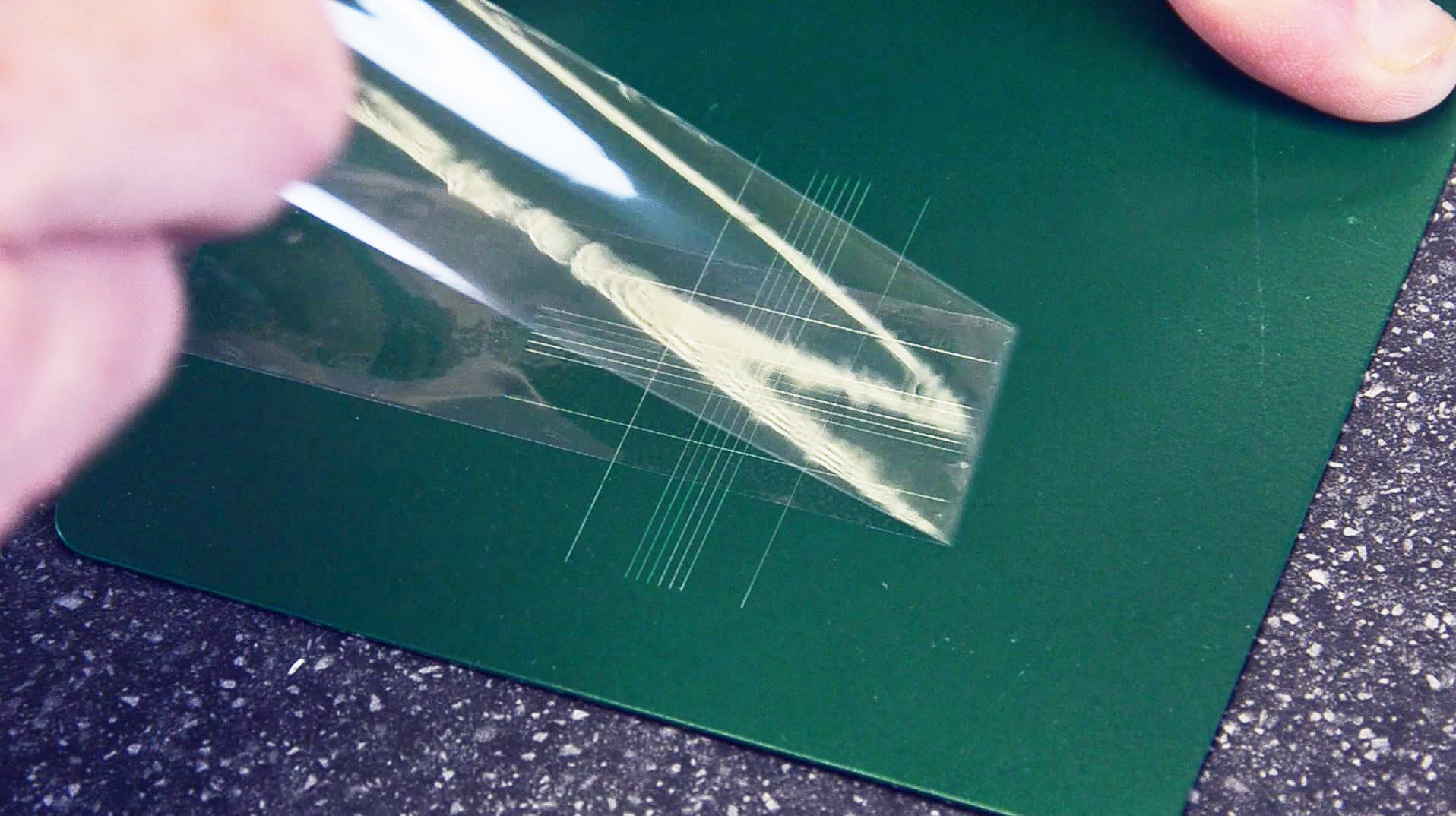

Place the centre of the adhesive tape over the lattice in a direction parallel to one set of cuts and smooth the adhesion tape into place over the area of the lattice. The procedure shall be carried out in such a way that the adhesive tape fully covers the lattice.

To ensure good contact with the coating, rub the adhesive tape firmly with a fingertip or fingernail.

Within a specified time after applying the adhesion tape, remove the adhesive tape by grasping the free end and pulling it off at an angle which is stated within the relevent standard (ISO 2409 or ASTM D 3359).

The adhesive tape is removed at the angle sitpulated in the relevant standard (ISO 2409 or ASTM D 3359)

The adhesive tape is removed at the angle sitpulated in the relevant standard (ISO 2409 or ASTM D 3359)The operation of applying and removing the adhesive tape can be carried out more than once, depending on the kind of coating and cutting direction. A new piece of adhesion tape shall be used for each lattice area.

When testing coatings on non-porous substrates, the back side of the adhesive tape after pull-off can be evaluated visually for any potential residues of the substrate. This practice can be used as a screening test for the correct cross-cut tool.

Note: while using the same pictorial references for the failure of the coating, the two standards actually assign a rating for the adhesion in the opposite manner. The ISO 0-5 represents best to worst whilst the ASTM 5B-0B represents best to worst.

-

- Technical Information

-

Technical SpecificationElcometer 99 Adhesive Tape

- Downloads

-

Downloads

- Part Numbers

-

Part NumbersElcometer 99 Adhesive TapeNo data found!!

-

Adhesion Tape (1 roll) ASTM D 3359

Adhesion Tape (1 roll) ASTM D 3359- Part Number : K0001539M001

-

Adhesion Tape (2 rolls) ASTM D 3359

Adhesion Tape (2 rolls) ASTM D 3359- Part Number : T9998894-

-

Adhesive Tape (1 roll) ISO 2409

Adhesive Tape (1 roll) ISO 2409- Part Number : T9999358-1

-

Adhesive Tape (2 rolls) ISO 2409

Adhesive Tape (2 rolls) ISO 2409- Part Number : T9999358-2

-

- Home

- Coatings Inspection

- Coatings Inspection Division

- Adhesion Testers

- Elcometer 99 Adhesive Tape

Elcometer 99 Adhesive Tape

- Protective Coatings

- Industrial Finishing

Used as part of the cross hatch adhesion test, the Elcometer 99 Adhesive Tape is used to remove loose particles of paint from a lattice pattern.

Summary

Elcometer 99 Adhesive Tape

Designed to be used after a cross-cut (cross hatch) adhesion test has be undertaken, the Elcometer 99 Adhesive Tape can be used to remove any loose paint particles from the lattice pattern.

This allows the inspector to determine the degree of coating removal to the relevent standard being used (ISO 2409 or ASTM D 3359), in accordance with the chart provided.

The Elcometer 99 Adhesive Tape can be used with either:

Elcometer 107 Cross Hatch Cutter

Elcometer 1542 Cross Hatch Adhesion Tester

Key Features

Elcometer 99 Adhesive Tape

How to use the Elcometer 99 Adhesive Tape

Place the centre of the adhesive tape over the lattice in a direction parallel to one set of cuts and smooth the adhesion tape into place over the area of the lattice. The procedure shall be carried out in such a way that the adhesive tape fully covers the lattice.

To ensure good contact with the coating, rub the adhesive tape firmly with a fingertip or fingernail.

Within a specified time after applying the adhesion tape, remove the adhesive tape by grasping the free end and pulling it off at an angle which is stated within the relevent standard (ISO 2409 or ASTM D 3359).

The adhesive tape is removed at the angle sitpulated in the relevant standard (ISO 2409 or ASTM D 3359)

The adhesive tape is removed at the angle sitpulated in the relevant standard (ISO 2409 or ASTM D 3359)The operation of applying and removing the adhesive tape can be carried out more than once, depending on the kind of coating and cutting direction. A new piece of adhesion tape shall be used for each lattice area.

When testing coatings on non-porous substrates, the back side of the adhesive tape after pull-off can be evaluated visually for any potential residues of the substrate. This practice can be used as a screening test for the correct cross-cut tool.

Note: while using the same pictorial references for the failure of the coating, the two standards actually assign a rating for the adhesion in the opposite manner. The ISO 0-5 represents best to worst whilst the ASTM 5B-0B represents best to worst.

Technical SpecificationElcometer 99 Adhesive TapePart NumbersElcometer 99 Adhesive TapeNo data found!!-

Adhesion Tape (1 roll) ASTM D 3359

Adhesion Tape (1 roll) ASTM D 3359- Part Number : K0001539M001

-

Adhesion Tape (2 rolls) ASTM D 3359

Adhesion Tape (2 rolls) ASTM D 3359- Part Number : T9998894-

-

Adhesive Tape (1 roll) ISO 2409

Adhesive Tape (1 roll) ISO 2409- Part Number : T9999358-1

-

Adhesive Tape (2 rolls) ISO 2409

Adhesive Tape (2 rolls) ISO 2409- Part Number : T9999358-2

- Part Numbers

- Downloads

-