Non-Destructive Dry Film Thickness Measurement

As the title indicates, the coating thickness is measured using methods which do not damage the coating or the substrate in any way. Non-destructive techniques include:

- Magnetic – magnetic strength is reduced as the coating thickness increases (for ferrous substrates only)

- Magnetic induction

- Eddy current

- Hall Effect

- Ultrasonic

- Phase shift

- ß back scatter

- X-ray fluorescence

Magnetic/Type 1

Using the simple principle that the amount of force required to pull a magnet from an uncoated ferrous substrate is greater than the force required to pull the same magnet off a coated substrate; the idea of a non-destructive coating thickness gauge was born.

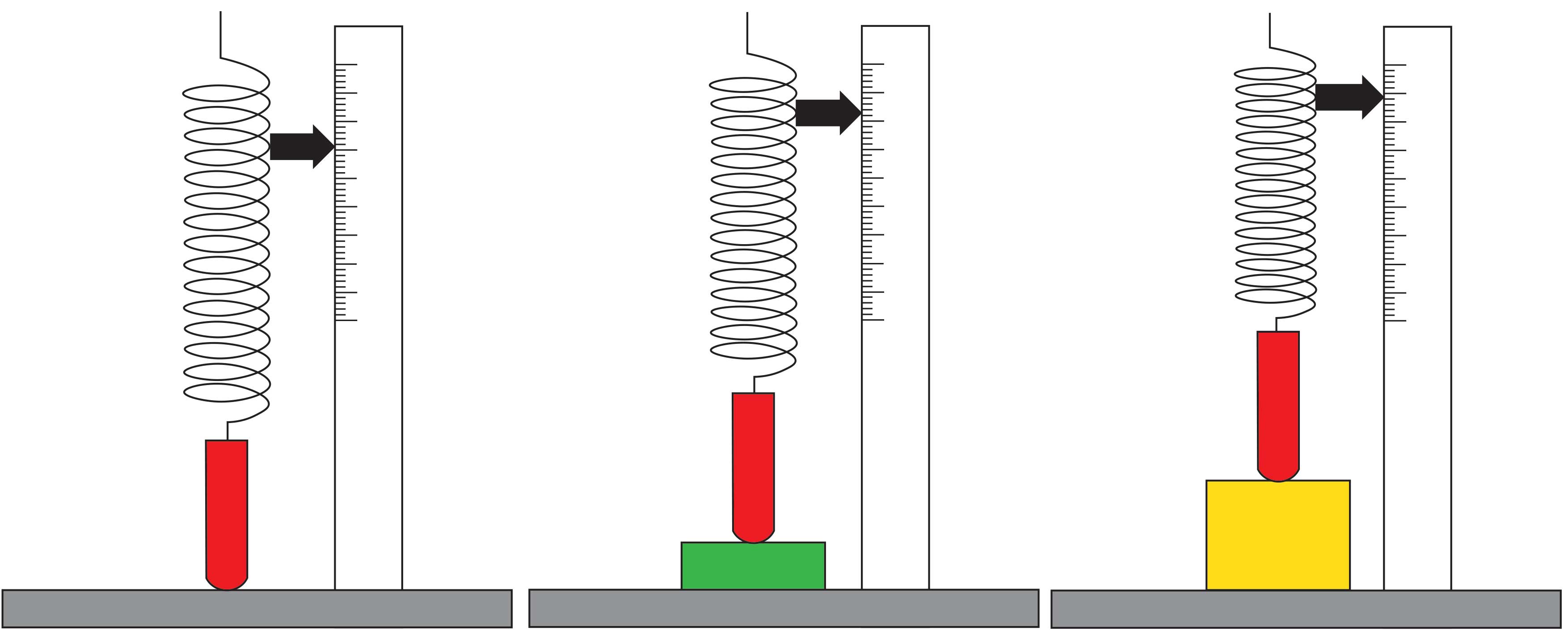

To make a basic coating thickness gauge, simply take a magnet, attach a spring (with a pointer) and record on a scale the point at which the magnet pulls off the uncoated substrate when lifted off. Repeat the steps with a number of foils of different known thicknesses (measured using a micrometer or similar device) and record on the scale rule.

It is now possible to measure an unknown thickness by comparing the force (F) required to pull off the magnet against the scale between the thickness of the foils used in the scale rule creation. This is the basis for all pencil-type gauges.

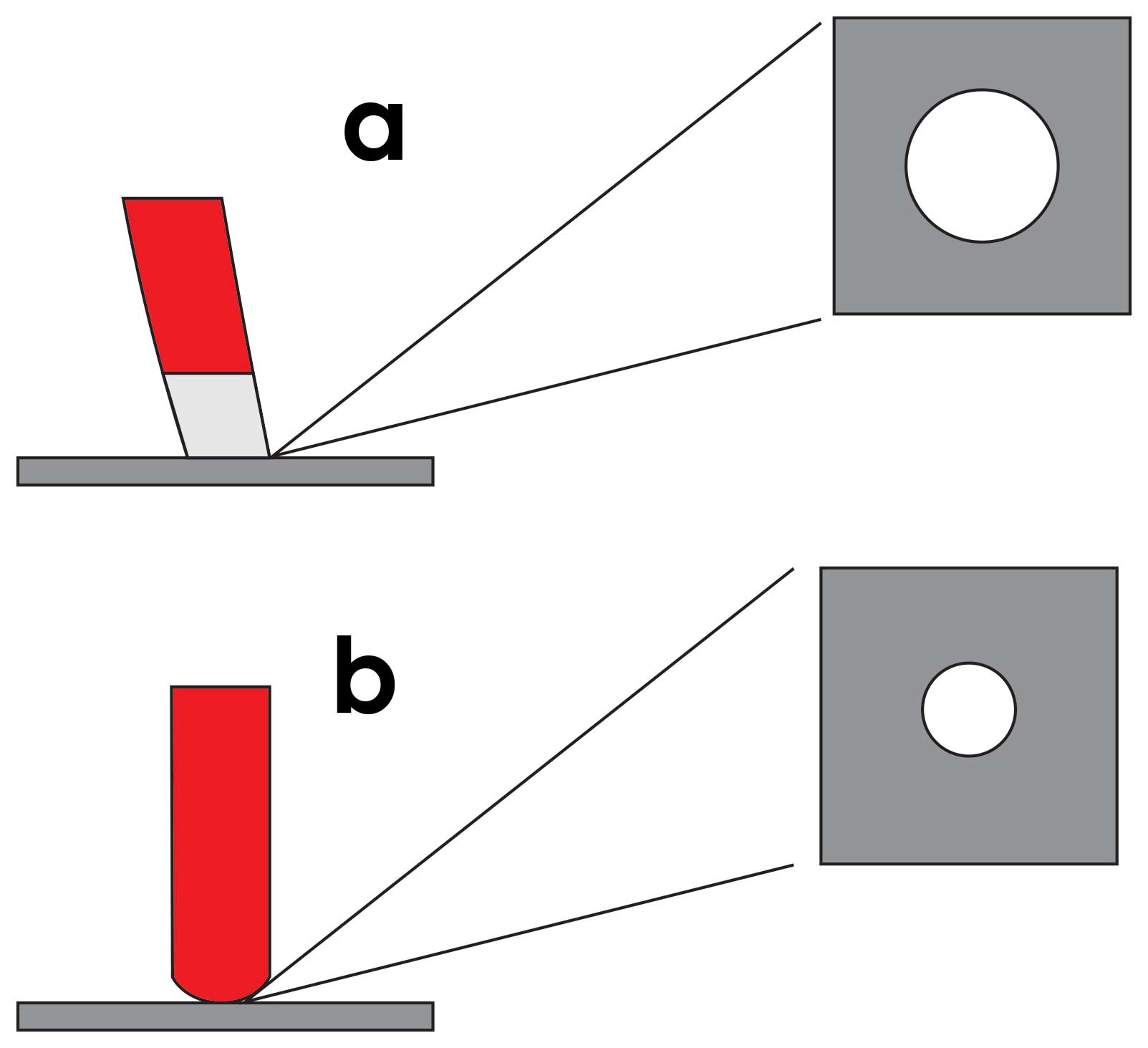

A flat-ended magnet provides a larger area of measurement (a) rather than a point measurement. A spherical end provides a smaller, point measurement (b) thereby improving accuracy.

Using this rudimentary design will provide typical accuracies of approximately 15% at best, mainly due to the accuracies in the spring. One method of improvement is to eliminate the effects of gravity on the measured value of the required force.

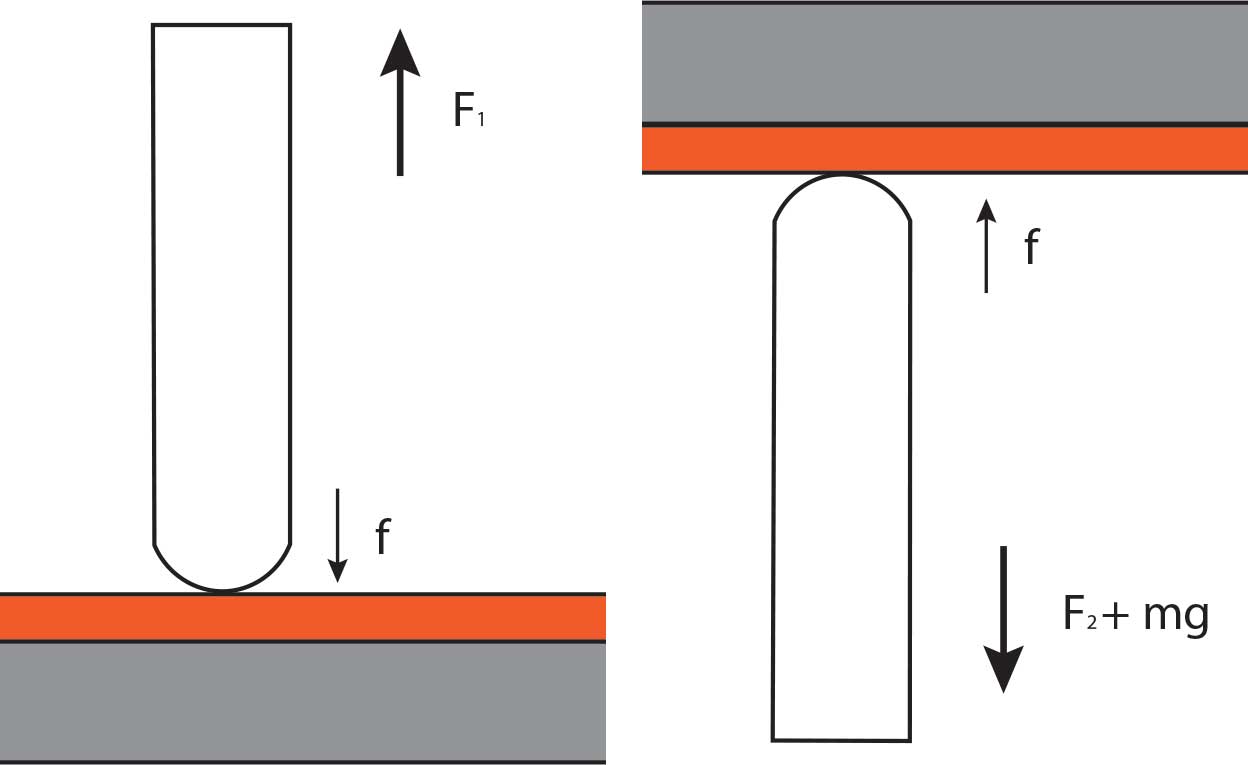

In the first diagram below, “F” is the force required to remove the magnet from the surface and “f” is the force recorded by the gauge. In this case, F = f.

In the second diagram, “F” is still the force required to remove the magnet from the surface and “f” is still the force recorded by the gauge. “m” is the mass of the gauge. Now F = f + mg.

Therefore, although the coating thickness is the same in both cases, the value recorded by the gauge is greater in the first example than it is in the second.

The Elcometer 101

In 1947, we created our very first patented coating thickness gauge known as the Elcometer 101.

The very first patented coating thickness gauge was the Elcometer 101 which was first granted a patent in 1947. The principle used a horseshoe magnet as the changes in the magnetic flux generated the proximity of a ferrous substrate to the magnet. This is because the magnetic flux increases the closer the magnet is to the substrate.

It was identified that a pointer attached to a hairspring could, when positioned in the middle of the horseshoe magnet, be used to measure the magnetic flux. By using this pointer and foils of known thickness, a more accurate thickness gauge could be developed (+/-10%) and it was this gauge which created the Elcometer name, originally manufactured as the Elcometer 101.

ELCo - meter: the meter from the East Lancashire Chemical Company

Weighted to improve accuracy further, a fulcrum is used to counteract the mass of the magnet, allowing for greater accuracy and repeatability of the gauge on various surface angles. A circular spring is coiled in the middle, appropriately attached to the fulcrum. As the spring is rotated the force applied to the magnet is increased until it pops off the surface.

Need Support from the Elcometer Experts?

As leading professionals in the manufacture of coating inspection equipment, we pride ourselves on providing coating inspection professionals with measuring equipment to ensure their testing is accurate, reliable and to industry Standards.

If you'd like the support of our team of professionals, get in touch with us today.