Transducers Characteristics Explained

Elcometer NDT offer a state-of-the-art range of Ultrasonic Gauge transducers.

When selecting a transducer it is important to choose one which will meet the specific application's needs. The type of material to be tested, the measurement range, the shape of the substrate (curved or flat) and the size of the material should be considered when selecting the appropriate transducer.

Selecting the right ultrasonic transducer

Selecting the right ultrasonic transducer for your application is essential to maximise performance.

Choosing the right frequency/diameter combination for the measurement application

Different materials have different acoustic properties. In some a sound wave can travel easily, in others it's absorbed which can make achieving an accurate measurement difficult.

Different frequencies of sound allow measurement of different materials, so when selecting a transducer the material type and therefore the frequency are the first consideration.

Low frequency ultrasonic transducers have the highest power and can penetrate deeply into a material in the same way that the bass notes of music from a car stereo can penetrate the body of a car and be heard outside. Low frequency ultrasonic transducers are best materials that absorb sound like plastics or composites. A low frequency transducer increases the chance of getting a strong return echo and a good quality measurement on these materials.

High frequency ultrasonic transducers are ideal for precision measurement because the pulse they emit is highly focused, reducing the risk of return echos outside of the measurement area. The high frequency and shorter wavelength also lends itself well to measuring thin materials. A third advantage is that high frequency ultrasonic transducers reduce troublesome “surface noise” that can be present on some metals such as aluminium or titanium and can cause measurement error.

Larger diameter probes feature larger crystals which transmit and receive the sound wave. A large crystal transmitter will produce a more powerful sound wave and a larger receiving crystal will be more sensitive. As a result, larger ultrasonic transducers tend to have better penetration characteristics than the smaller types. If this extended range is not required, the smaller ultrasonic transducers can be placed more precisely and in hard to reach areas such as narrow grooves in a material. Smaller diameter transducers also couple more easily to curved surfaces so have applications in corrosion testing pipes and cylinders.

What connection should it have?

Potted

The ultrasonic transducer is strongly secured to the cable at the factory

Microdot

The ultrasonic transducer is attached using

two small screw type connectors, enabling replacement of the cable in case of accidental damage or wear

LEMO 00

Large diameter ultrasonic transducers may

be purchased with the sturdy Lemo 00 connection on the probe side for increased wear resistance

Frequency & Diameter Disks

Each ultrasonic transducer can be easily identified by the disk on the top.

Single Element

A single element transducer features a single crystal that sends and receives the pulse and are made for high frequency use. Mostly for use with the flaw detectors.

Armoured

Fitted with a heavy duty armoured cable for increased wear resistance.

Dual Element

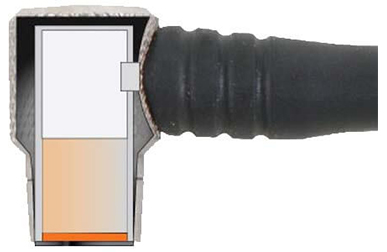

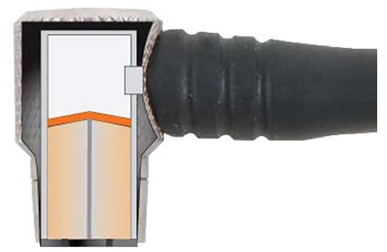

A dual element transducer consists of two crystal elements housed in the same case, separated by an acoustic barrier. Mostly for use with the thickness gauges.

Pencil Probe: 1/16" Tip

Pencil style transducer with a straight or 90° angle tip for limited access applications. Can only be used with the PG70ABDL.

High Wear

Designed for use with the FD700+ flaw detectors features a reinforced tip design for abrasive surface applications. Also available with a high power composite crystal for better penetration.

Hi Temp

A high temperature transducer to be used on hot surfaces. High temperature transducers are available up to either 343°C (650°F) or 482°C (900°F).

Underwater

Specially designed for use with the UG20DL underwater gauge.

Finger Tip

General purpose contact transducers for use with the FD700+ series, featuring good near surface resolution. Also available with a high power composite crystal for better penetration or as a slim line model for accurate positioning.

Delay Line

Small part used with single element transducers to slow the sound pulse down to allow measurement on thinner materials. Can only be used with the precision gauges.

Super Standard

High power transducer for increased range and penetration through sound absorbing materials.

Cylinder Probes

Transducers featuring a curved wearface for measuring inside cylinders and engine blocks. Available for measuring on Iron (Iron) or Aluminium (Alum).

High Damped

Limiting the duration or decreasing the amplitude of vibrations. For use with EE (ThruPaint™) only.

Low Profile

Small body transducer to enable measurement in small spaces, available with either a standard probe or 25mm (1") or 225mm (9") handles.

Composite

High gain transducer for increased power and penetration.

Shear Wave

Large Single element transducer designed to be used with angle beam wedges for a powerful flaw detection solution.

High Resolution

Features increased near surface resolution, ideal for use on thin substrates.

Membrane

Transducer with a soft, flexible wearface that increases contact quality between the transducer and the part on rough surfaces. Also available with a high power composite crystal for better penetration.

Coating Thickness

Utilising ThruPaint™ technology these transducers are capable of simultaneous measurement of coating and material thickness.