Elcometer KARA Double Diaphragm Transfer Pumps

Ideal for use with water and solvent based materials, the Elcometer KARA double diaphragm transfer pumps are engineered to quickly and consistently supply fluid smoothly.

- Summary

-

Summary

-

With high 30-40 litres (6.6-8.8 gallons) per minute fluid delivery capacity, a smooth air change over valve and aluminium, stainless steel & PTFE polyamide construction Elcometer KARA transfer pumps are built to last.

Powerful performance

With up to 40 litres per minute maximum free flow, the Elcometer Kara's powerful fluid circulation keeps paint homogenous whilst ensuring pulse-free material flows to the application points, even with long fluid hoses. In fact, the Elcometer Kara's high performance can support multiple spray guns at once.Robust

Rugged stainless steel and aluminium construction to handle a wide variety of fluid types.Excellent cost of ownership

Designed with low air consumption, the Elcometer Kara helps to lower expensive compressor running costs.Versatile

Whether you are working with water based, solvent based or abrasive materials there is an Elcometer Kara Transfer Pump available with optional drum lid and rotary agitator to suit your requirements.

-

- Key Features

-

Key Features

Elcometer KARA Double Diaphragm Transfer Pumps

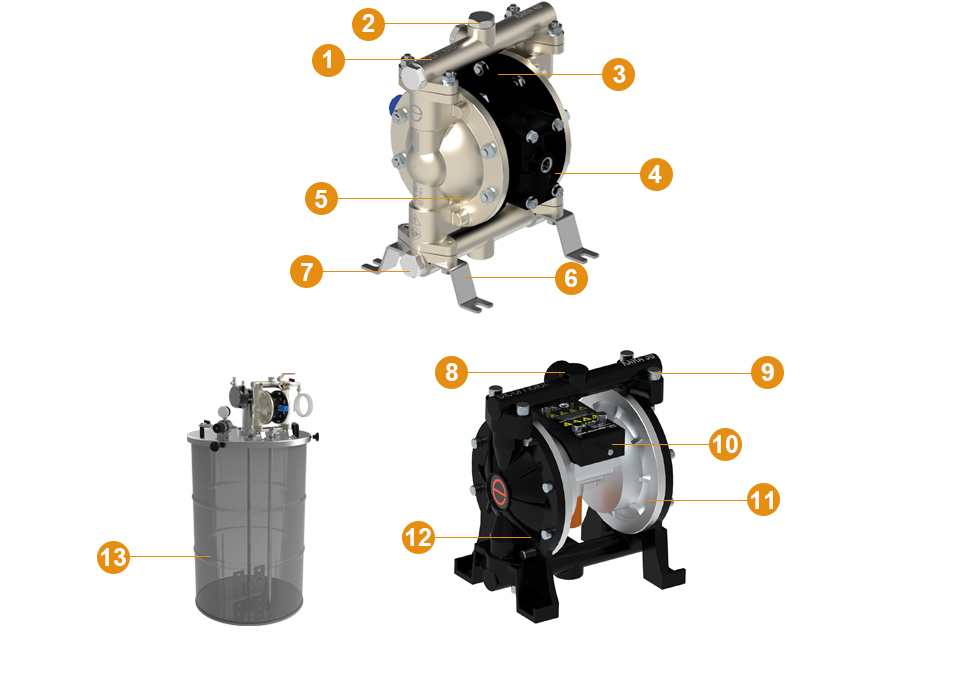

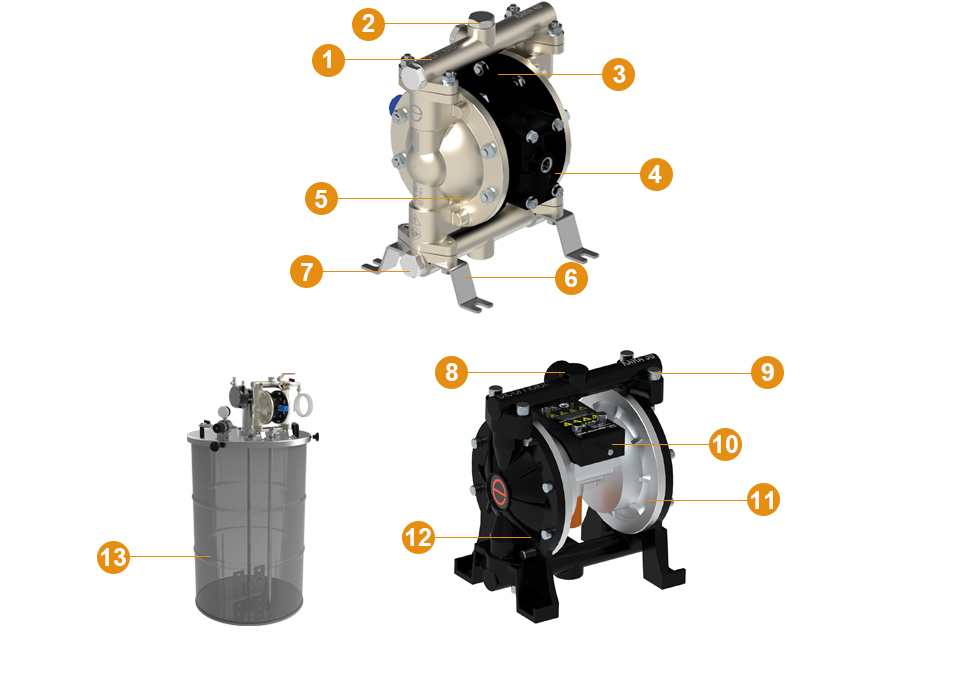

1) 40lpm (10.6gpm) fluid delivery capacity

2) Versatile front and top fluid outlets for ease of use

3) Low pulsing air distribution manifold uses durable metal to metal technology to prevent pump stalling

4) KARA 40 supplied with Polypropylene seats and PTFE balls for water based and solvent materials

5) Durable lightweight anodized aluminium pump housing

6) Fast and easy to service on site using standard tools to reduce downtime

7) KARA 40A Abrasive Transfer Pump is supplied with stainless steel balls and seats to suit ceramic based materials

8) Versatile front and top fluid outlets for ease of use

9) Stainless steel balls and seats for water based and semi viscous materials

10) Modular air valve provides smooth and rapid changeover for increased efficiency and minimised down time

11) Durable lightweight anodized aluminium pump housing

12) Lightweight, anti-corrosive Polyethylene (LDPE) centre housing

13) Available with 200 litre (44 gallons) drum lid and rotary agitator

The Elcometer KARA is suitable for use with...

The Elcometer KARA range is suitable for use with Solvent Based and Water Based materials as well a wide range of products.

Kara 30 & Kara 40 Single component (1k) epoxies Single component (1k) polyurethanes Plural (2k) & multi-component (3k) low viscose polyurethane epoxies¹ Water based enamel coatings Solvent-based primer and base coats Quick air dry enamel coatings Metallic-based epoxy coatings Wood stains High solid pre-catalysed lacquers Acid-catalyst wood lacquers Waterborne lacquers UV curable epoxies Water based UV coatings 1k fire-retardant coatings Natural wood oils Antimicrobial lacquers Sealers and undercoats - Kara 1-40A Inorganic zinc coatings Stove enamels Graphene-based materials Water based ceramic glaze coatings Abrasive coatings for cosmetic & glass Vitreous enamel Vitreous sanitaryware glaze Industrial porcelain coating Ceramic tableware glaze

-

- Technical Information

-

Technical SpecificationElcometer KARA Double Diaphragm Transfer Pumps

KARA 30 KARA 40 KARA 40A Ratio 1 : 1 1 : 1 1 : 1 Maximum fluid particle size** 0.25mm (10mils) 0.25mm (10mils) 0.25mm (10mils) Fluid temperature range 4.4 - 60°C (40 - 140°F) 4.4 - 60°C (40 - 140°F) 4.4 - 60°C (40 - 140°F) Fluid inlet size 1/2” BSP Male 1/2” BSP Male 1/2” BSP Male Fluid outlet size 1/2” BSP Male 1/2” BSP Male 1/2” BSP Male Compatible Products that can be pumped Solvent and waterbased products Solvent and waterbased products Abrasive, solvent and waterbased products COMPOSITION OF PARTS IN CONTACT WITH PRODUCT (WET) Seats Stainless Steel Polypropylene Stainless Steel Balls Stainless Steel PTFE Stainless Steel Diaphragm Polyethylene PTFE PTFE Pump Body / Cylinder Housing Polyethylene / Aluminium PTFE / Aluminium PTFE / Aluminium Centre Section Aluminium Polyamide Polyamide EXTERNAL PUMP PARTS (DRY) Pump Body / Cylinder Housing Polyamide / Aluminium Polyamide / Aluminium Polyamide / Aluminium AIR Air Pressure Operating Range 1-6bar (14-87psi) 1-7bar (14-101psi) 1-7bar (14-101psi) Air Consumption at 3 bar (43.5 psi) & 7.5 CPM 1.8lpm (0.06cfm) - - Air Consumption at 3 bar (43.5 psi) & 16 CPM - 7.92lpm (0.28cfm) 7.92lpm (0.28cfm) Maximum Air Inlet Pressure 6bar (87psi) 7bar (101psi) 7bar (101psi) Air Inlet 1/4” BSP Female 1/4” BSP Female 1/4” BSP Female Air Exhaust / Silencer Port 1/2” BSP Female 1/2” BSP Female 1/2” BSP Female Compressor Requirements (Minimum) No Minimum No Minimum No Minimum Ambient Air Temperature Operating Range 4.4 - 60°C (40 - 140°F) 4.4 - 60°C (40 - 140°F) 4.4 - 60°C (40 - 140°F) FLUID / PRODUCT Maximum Fluid Outlet Working Pressure 6bar (87psi) 7bar (101psi) 7bar (101psi) Product Output per Cycle 80 cc (2.61 fl oz) 165 cc (4.61 fl oz) 165 cc (4.61 fl oz) Maximum Free Flow 30 lpm (7.9 gpm) 40 lpm (10.6 gpm) 40 lpm (10.6 gpm) Free Flow Delivery @ 60 CPM* 4.8 lpm (1.26 gpm) 10 lpm (2.64 gpm) 10 lpm (2.64 gpm) DIMENSIONS Weight (Pump only) 3.3 kg (7.3lb) 4.6kg (10.1lb) 4.8kg (10.6lb) Dimensions (Wall Mount) 185 x 141 x 215mm (7.3 x 5.6 x 8.5”) 210 x 204 x 270mm (8.3 x 8 x 10.6") 210 x 204 x 270mm (8.3 x 8 x 10.6") KARA 30 Ratio 1 : 1 Maximum fluid particle size** 0.25mm (10mils) Fluid temperature range 4.4 - 60°C (40 - 140°F) Fluid inlet size 1/2” BSP Male Fluid outlet size 1/2” BSP Male Compatible Products that can be pumped Solvent and waterbased products COMPOSITION OF PARTS IN CONTACT WITH PRODUCT (WET) Seats Stainless Steel Balls Stainless Steel Diaphragm Polyethylene Pump Body / Cylinder Housing Polyethylene / Aluminium Centre Section Aluminium EXTERNAL PUMP PARTS (DRY) Pump Body / Cylinder Housing Polyamide / Aluminium AIR Air Pressure Operating Range 1-6bar (14-87psi) Air Consumption at 3 bar (43.5 psi) & 7.5 CPM 1.8lpm (0.06cfm) Air Consumption at 3 bar (43.5 psi) & 16 CPM - Maximum Air Inlet Pressure 6bar (87psi) Air Inlet 1/4” BSP Female Air Exhaust / Silencer Port 1/2” BSP Female Compressor Requirements (Minimum) No Minimum Ambient Air Temperature Operating Range 4.4 - 60°C (40 - 140°F) FLUID / PRODUCT Maximum Fluid Outlet Working Pressure 6bar (87psi) Product Output per Cycle 80 cc (2.61 fl oz) Maximum Free Flow 30 lpm (7.9 gpm) Free Flow Delivery @ 60 CPM* 4.8 lpm (1.26 gpm) DIMENSIONS Weight (Pump only) 3.3 kg (7.3lb) Dimensions (Wall Mount) 185 x 141 x 215mm (7.3 x 5.6 x 8.5”) KARA 40 Ratio 1 : 1 Maximum fluid particle size** 0.25mm (10mils) Fluid temperature range 4.4 - 60°C (40 - 140°F) Fluid inlet size 1/2” BSP Male Fluid outlet size 1/2” BSP Male Compatible Products that can be pumped Solvent and waterbased products COMPOSITION OF PARTS IN CONTACT WITH PRODUCT (WET) Seats Polypropylene Balls PTFE Diaphragm PTFE Pump Body / Cylinder Housing PTFE / Aluminium Centre Section Polyamide EXTERNAL PUMP PARTS (DRY) Pump Body / Cylinder Housing Polyamide / Aluminium AIR Air Pressure Operating Range 1-7bar (14-101psi) Air Consumption at 3 bar (43.5 psi) & 7.5 CPM - Air Consumption at 3 bar (43.5 psi) & 16 CPM 7.92lpm (0.28cfm) Maximum Air Inlet Pressure 7bar (101psi) Air Inlet 1/4” BSP Female Air Exhaust / Silencer Port 1/2” BSP Female Compressor Requirements (Minimum) No Minimum Ambient Air Temperature Operating Range 4.4 - 60°C (40 - 140°F) FLUID / PRODUCT Maximum Fluid Outlet Working Pressure 7bar (101psi) Product Output per Cycle 165 cc (4.61 fl oz) Maximum Free Flow 40 lpm (10.6 gpm) Free Flow Delivery @ 60 CPM* 10 lpm (2.64 gpm) DIMENSIONS Weight (Pump only) 4.6kg (10.1lb) Dimensions (Wall Mount) 210 x 204 x 270mm (8.3 x 8 x 10.6") KARA 40A Ratio 1 : 1 Maximum fluid particle size** 0.25mm (10mils) Fluid temperature range 4.4 - 60°C (40 - 140°F) Fluid inlet size 1/2” BSP Male Fluid outlet size 1/2” BSP Male Compatible Products that can be pumped Abrasive, solvent and waterbased products COMPOSITION OF PARTS IN CONTACT WITH PRODUCT (WET) Seats Stainless Steel Balls Stainless Steel Diaphragm PTFE Pump Body / Cylinder Housing PTFE / Aluminium Centre Section Polyamide EXTERNAL PUMP PARTS (DRY) Pump Body / Cylinder Housing Polyamide / Aluminium AIR Air Pressure Operating Range 1-7bar (14-101psi) Air Consumption at 3 bar (43.5 psi) & 7.5 CPM - Air Consumption at 3 bar (43.5 psi) & 16 CPM 7.92lpm (0.28cfm) Maximum Air Inlet Pressure 7bar (101psi) Air Inlet 1/4” BSP Female Air Exhaust / Silencer Port 1/2” BSP Female Compressor Requirements (Minimum) No Minimum Ambient Air Temperature Operating Range 4.4 - 60°C (40 - 140°F) FLUID / PRODUCT Maximum Fluid Outlet Working Pressure 7bar (101psi) Product Output per Cycle 165 cc (4.61 fl oz) Maximum Free Flow 40 lpm (10.6 gpm) Free Flow Delivery @ 60 CPM* 10 lpm (2.64 gpm) DIMENSIONS Weight (Pump only) 4.8kg (10.6lb) Dimensions (Wall Mount) 210 x 204 x 270mm (8.3 x 8 x 10.6") 1. With suction hose or deposit and pump output filter.

2. Product Output per Cycle = Fluid Displacement per Cycle

2.Maximum Free Flow is the volume of fluid the pump is able to transfer at maximum speed and at an undefined number of cycles.

3. Maximum values with water as test media.

lpm: Litres per minute fl oz/min: US Fluid ounces per minute gpm: US Gallons per minute CPM: Cycles per minute

-

- Downloads

-

- Part Numbers

-

Part NumbersElcometer KARA Double Diaphragm Transfer PumpsNo data found!!

-

Elcometer Kara 30 Double Diaphragm Transfer Pump

Elcometer Kara 30 Double Diaphragm Transfer Pump- Part Number : PTD130AS

-

Elcometer Kara 40 Double Diaphragm Transfer Pump

Elcometer Kara 40 Double Diaphragm Transfer Pump- Part Number : PTD140AS

-

Elcometer Kara 40A Double Diaphragm Transfer Pump for Abrasive Materials

Elcometer Kara 40A Double Diaphragm Transfer Pump for Abrasive Materials- Part Number : PTD140AAS

-

Elcometer 200 Drum Cover with Elcometer Kara 40 Double Diaphragm Transfer Pump

Elcometer 200 Drum Cover with Elcometer Kara 40 Double Diaphragm Transfer Pump- Part Number : PSD140AS-C

-

Elcometer 200 Drum Cover with Elcometer Kara 40 Double Diaphragm Transfer Pump & Rotary Agitator

Elcometer 200 Drum Cover with Elcometer Kara 40 Double Diaphragm Transfer Pump & Rotary Agitator- Part Number : PSD140AS-C-RA

- Accessories

-

AccessoriesElcometer KARA Double Diaphragm Transfer Pumps

Part Number: 56414024

Part Number: 56414024 Part Number: 56414025

Part Number: 56414025 Part Number: 56414027

Part Number: 56414027 Part Number: 56414026

Part Number: 56414026 Part Number: PT56414130

Part Number: PT56414130 Part Number: PT56414039

Part Number: PT56414039 Part Number: PT56414044

Part Number: PT56414044 Part Number: PT56414040

Part Number: PT56414040 Part Number: PT56414041

Part Number: PT56414041 Part Number: PT56414042

Part Number: PT56414042 Part Number: PT56414028

Part Number: PT56414028 Part Number: PT56414116

Part Number: PT56414116 Part Number: PT56414117

Part Number: PT56414117 Part Number: PT56414115

Part Number: PT56414115 Part Number: PT56414118

Part Number: PT56414118 Part Number: PT56414119

Part Number: PT56414119

-

- Home

- Spray Equipment

- Transfer Pumps & Drum Covers

- Elcometer KARA Double Diaphragm Transfer Pumps

Elcometer KARA Double Diaphragm Transfer Pumps

Ideal for use with water and solvent based materials, the Elcometer KARA double diaphragm transfer pumps are engineered to quickly and consistently supply fluid smoothly.

Summary

Elcometer KARA Double Diaphragm Transfer Pumps

With high 30-40 litres (6.6-8.8 gallons) per minute fluid delivery capacity, a smooth air change over valve and aluminium, stainless steel & PTFE polyamide construction Elcometer KARA transfer pumps are built to last.

Powerful performance

With up to 40 litres per minute maximum free flow, the Elcometer Kara's powerful fluid circulation keeps paint homogenous whilst ensuring pulse-free material flows to the application points, even with long fluid hoses. In fact, the Elcometer Kara's high performance can support multiple spray guns at once.Robust

Rugged stainless steel and aluminium construction to handle a wide variety of fluid types.Excellent cost of ownership

Designed with low air consumption, the Elcometer Kara helps to lower expensive compressor running costs.Versatile

Whether you are working with water based, solvent based or abrasive materials there is an Elcometer Kara Transfer Pump available with optional drum lid and rotary agitator to suit your requirements.Key Features

Elcometer KARA Double Diaphragm Transfer Pumps

1) 40lpm (10.6gpm) fluid delivery capacity

2) Versatile front and top fluid outlets for ease of use

3) Low pulsing air distribution manifold uses durable metal to metal technology to prevent pump stalling

4) KARA 40 supplied with Polypropylene seats and PTFE balls for water based and solvent materials

5) Durable lightweight anodized aluminium pump housing

6) Fast and easy to service on site using standard tools to reduce downtime

7) KARA 40A Abrasive Transfer Pump is supplied with stainless steel balls and seats to suit ceramic based materials

8) Versatile front and top fluid outlets for ease of use

9) Stainless steel balls and seats for water based and semi viscous materials

10) Modular air valve provides smooth and rapid changeover for increased efficiency and minimised down time

11) Durable lightweight anodized aluminium pump housing

12) Lightweight, anti-corrosive Polyethylene (LDPE) centre housing

13) Available with 200 litre (44 gallons) drum lid and rotary agitator

The Elcometer KARA is suitable for use with...

The Elcometer KARA range is suitable for use with Solvent Based and Water Based materials as well a wide range of products.

Kara 30 & Kara 40 Single component (1k) epoxies Single component (1k) polyurethanes Plural (2k) & multi-component (3k) low viscose polyurethane epoxies¹ Water based enamel coatings Solvent-based primer and base coats Quick air dry enamel coatings Metallic-based epoxy coatings Wood stains High solid pre-catalysed lacquers Acid-catalyst wood lacquers Waterborne lacquers UV curable epoxies Water based UV coatings 1k fire-retardant coatings Natural wood oils Antimicrobial lacquers Sealers and undercoats - Kara 1-40A Inorganic zinc coatings Stove enamels Graphene-based materials Water based ceramic glaze coatings Abrasive coatings for cosmetic & glass Vitreous enamel Vitreous sanitaryware glaze Industrial porcelain coating Ceramic tableware glaze Technical SpecificationElcometer KARA Double Diaphragm Transfer PumpsKARA 30 KARA 40 KARA 40A Ratio 1 : 1 1 : 1 1 : 1 Maximum fluid particle size** 0.25mm (10mils) 0.25mm (10mils) 0.25mm (10mils) Fluid temperature range 4.4 - 60°C (40 - 140°F) 4.4 - 60°C (40 - 140°F) 4.4 - 60°C (40 - 140°F) Fluid inlet size 1/2” BSP Male 1/2” BSP Male 1/2” BSP Male Fluid outlet size 1/2” BSP Male 1/2” BSP Male 1/2” BSP Male Compatible Products that can be pumped Solvent and waterbased products Solvent and waterbased products Abrasive, solvent and waterbased products COMPOSITION OF PARTS IN CONTACT WITH PRODUCT (WET) Seats Stainless Steel Polypropylene Stainless Steel Balls Stainless Steel PTFE Stainless Steel Diaphragm Polyethylene PTFE PTFE Pump Body / Cylinder Housing Polyethylene / Aluminium PTFE / Aluminium PTFE / Aluminium Centre Section Aluminium Polyamide Polyamide EXTERNAL PUMP PARTS (DRY) Pump Body / Cylinder Housing Polyamide / Aluminium Polyamide / Aluminium Polyamide / Aluminium AIR Air Pressure Operating Range 1-6bar (14-87psi) 1-7bar (14-101psi) 1-7bar (14-101psi) Air Consumption at 3 bar (43.5 psi) & 7.5 CPM 1.8lpm (0.06cfm) - - Air Consumption at 3 bar (43.5 psi) & 16 CPM - 7.92lpm (0.28cfm) 7.92lpm (0.28cfm) Maximum Air Inlet Pressure 6bar (87psi) 7bar (101psi) 7bar (101psi) Air Inlet 1/4” BSP Female 1/4” BSP Female 1/4” BSP Female Air Exhaust / Silencer Port 1/2” BSP Female 1/2” BSP Female 1/2” BSP Female Compressor Requirements (Minimum) No Minimum No Minimum No Minimum Ambient Air Temperature Operating Range 4.4 - 60°C (40 - 140°F) 4.4 - 60°C (40 - 140°F) 4.4 - 60°C (40 - 140°F) FLUID / PRODUCT Maximum Fluid Outlet Working Pressure 6bar (87psi) 7bar (101psi) 7bar (101psi) Product Output per Cycle 80 cc (2.61 fl oz) 165 cc (4.61 fl oz) 165 cc (4.61 fl oz) Maximum Free Flow 30 lpm (7.9 gpm) 40 lpm (10.6 gpm) 40 lpm (10.6 gpm) Free Flow Delivery @ 60 CPM* 4.8 lpm (1.26 gpm) 10 lpm (2.64 gpm) 10 lpm (2.64 gpm) DIMENSIONS Weight (Pump only) 3.3 kg (7.3lb) 4.6kg (10.1lb) 4.8kg (10.6lb) Dimensions (Wall Mount) 185 x 141 x 215mm (7.3 x 5.6 x 8.5”) 210 x 204 x 270mm (8.3 x 8 x 10.6") 210 x 204 x 270mm (8.3 x 8 x 10.6") KARA 30 Ratio 1 : 1 Maximum fluid particle size** 0.25mm (10mils) Fluid temperature range 4.4 - 60°C (40 - 140°F) Fluid inlet size 1/2” BSP Male Fluid outlet size 1/2” BSP Male Compatible Products that can be pumped Solvent and waterbased products COMPOSITION OF PARTS IN CONTACT WITH PRODUCT (WET) Seats Stainless Steel Balls Stainless Steel Diaphragm Polyethylene Pump Body / Cylinder Housing Polyethylene / Aluminium Centre Section Aluminium EXTERNAL PUMP PARTS (DRY) Pump Body / Cylinder Housing Polyamide / Aluminium AIR Air Pressure Operating Range 1-6bar (14-87psi) Air Consumption at 3 bar (43.5 psi) & 7.5 CPM 1.8lpm (0.06cfm) Air Consumption at 3 bar (43.5 psi) & 16 CPM - Maximum Air Inlet Pressure 6bar (87psi) Air Inlet 1/4” BSP Female Air Exhaust / Silencer Port 1/2” BSP Female Compressor Requirements (Minimum) No Minimum Ambient Air Temperature Operating Range 4.4 - 60°C (40 - 140°F) FLUID / PRODUCT Maximum Fluid Outlet Working Pressure 6bar (87psi) Product Output per Cycle 80 cc (2.61 fl oz) Maximum Free Flow 30 lpm (7.9 gpm) Free Flow Delivery @ 60 CPM* 4.8 lpm (1.26 gpm) DIMENSIONS Weight (Pump only) 3.3 kg (7.3lb) Dimensions (Wall Mount) 185 x 141 x 215mm (7.3 x 5.6 x 8.5”) KARA 40 Ratio 1 : 1 Maximum fluid particle size** 0.25mm (10mils) Fluid temperature range 4.4 - 60°C (40 - 140°F) Fluid inlet size 1/2” BSP Male Fluid outlet size 1/2” BSP Male Compatible Products that can be pumped Solvent and waterbased products COMPOSITION OF PARTS IN CONTACT WITH PRODUCT (WET) Seats Polypropylene Balls PTFE Diaphragm PTFE Pump Body / Cylinder Housing PTFE / Aluminium Centre Section Polyamide EXTERNAL PUMP PARTS (DRY) Pump Body / Cylinder Housing Polyamide / Aluminium AIR Air Pressure Operating Range 1-7bar (14-101psi) Air Consumption at 3 bar (43.5 psi) & 7.5 CPM - Air Consumption at 3 bar (43.5 psi) & 16 CPM 7.92lpm (0.28cfm) Maximum Air Inlet Pressure 7bar (101psi) Air Inlet 1/4” BSP Female Air Exhaust / Silencer Port 1/2” BSP Female Compressor Requirements (Minimum) No Minimum Ambient Air Temperature Operating Range 4.4 - 60°C (40 - 140°F) FLUID / PRODUCT Maximum Fluid Outlet Working Pressure 7bar (101psi) Product Output per Cycle 165 cc (4.61 fl oz) Maximum Free Flow 40 lpm (10.6 gpm) Free Flow Delivery @ 60 CPM* 10 lpm (2.64 gpm) DIMENSIONS Weight (Pump only) 4.6kg (10.1lb) Dimensions (Wall Mount) 210 x 204 x 270mm (8.3 x 8 x 10.6") KARA 40A Ratio 1 : 1 Maximum fluid particle size** 0.25mm (10mils) Fluid temperature range 4.4 - 60°C (40 - 140°F) Fluid inlet size 1/2” BSP Male Fluid outlet size 1/2” BSP Male Compatible Products that can be pumped Abrasive, solvent and waterbased products COMPOSITION OF PARTS IN CONTACT WITH PRODUCT (WET) Seats Stainless Steel Balls Stainless Steel Diaphragm PTFE Pump Body / Cylinder Housing PTFE / Aluminium Centre Section Polyamide EXTERNAL PUMP PARTS (DRY) Pump Body / Cylinder Housing Polyamide / Aluminium AIR Air Pressure Operating Range 1-7bar (14-101psi) Air Consumption at 3 bar (43.5 psi) & 7.5 CPM - Air Consumption at 3 bar (43.5 psi) & 16 CPM 7.92lpm (0.28cfm) Maximum Air Inlet Pressure 7bar (101psi) Air Inlet 1/4” BSP Female Air Exhaust / Silencer Port 1/2” BSP Female Compressor Requirements (Minimum) No Minimum Ambient Air Temperature Operating Range 4.4 - 60°C (40 - 140°F) FLUID / PRODUCT Maximum Fluid Outlet Working Pressure 7bar (101psi) Product Output per Cycle 165 cc (4.61 fl oz) Maximum Free Flow 40 lpm (10.6 gpm) Free Flow Delivery @ 60 CPM* 10 lpm (2.64 gpm) DIMENSIONS Weight (Pump only) 4.8kg (10.6lb) Dimensions (Wall Mount) 210 x 204 x 270mm (8.3 x 8 x 10.6") 1. With suction hose or deposit and pump output filter.

2. Product Output per Cycle = Fluid Displacement per Cycle

2.Maximum Free Flow is the volume of fluid the pump is able to transfer at maximum speed and at an undefined number of cycles.

3. Maximum values with water as test media.

lpm: Litres per minute fl oz/min: US Fluid ounces per minute gpm: US Gallons per minute CPM: Cycles per minutePart NumbersElcometer KARA Double Diaphragm Transfer PumpsNo data found!!-

Elcometer Kara 30 Double Diaphragm Transfer Pump

Elcometer Kara 30 Double Diaphragm Transfer Pump- Part Number : PTD130AS

-

Elcometer Kara 40 Double Diaphragm Transfer Pump

Elcometer Kara 40 Double Diaphragm Transfer Pump- Part Number : PTD140AS

-

Elcometer Kara 40A Double Diaphragm Transfer Pump for Abrasive Materials

Elcometer Kara 40A Double Diaphragm Transfer Pump for Abrasive Materials- Part Number : PTD140AAS

-

Elcometer 200 Drum Cover with Elcometer Kara 40 Double Diaphragm Transfer Pump

Elcometer 200 Drum Cover with Elcometer Kara 40 Double Diaphragm Transfer Pump- Part Number : PSD140AS-C

-

Elcometer 200 Drum Cover with Elcometer Kara 40 Double Diaphragm Transfer Pump & Rotary Agitator

Elcometer 200 Drum Cover with Elcometer Kara 40 Double Diaphragm Transfer Pump & Rotary Agitator- Part Number : PSD140AS-C-RA

AccessoriesElcometer KARA Double Diaphragm Transfer Pumps Part Number: 56414024

Part Number: 56414024 Part Number: 56414025

Part Number: 56414025 Part Number: 56414027

Part Number: 56414027 Part Number: 56414026

Part Number: 56414026 Part Number: PT56414130

Part Number: PT56414130 Part Number: PT56414039

Part Number: PT56414039 Part Number: PT56414044

Part Number: PT56414044 Part Number: PT56414040

Part Number: PT56414040 Part Number: PT56414041

Part Number: PT56414041 Part Number: PT56414042

Part Number: PT56414042 Part Number: PT56414028

Part Number: PT56414028 Part Number: PT56414116

Part Number: PT56414116 Part Number: PT56414117

Part Number: PT56414117 Part Number: PT56414115

Part Number: PT56414115 Part Number: PT56414118

Part Number: PT56414118 Part Number: PT56414119

Part Number: PT56414119

- Part Numbers

-