FD800 Bench Top Flaw Detectors

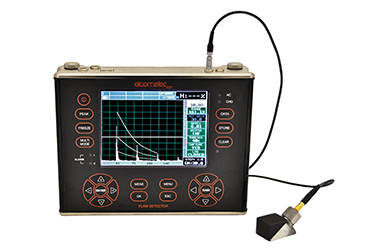

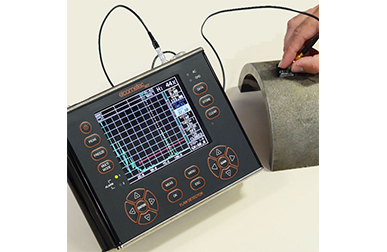

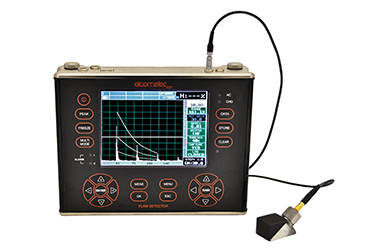

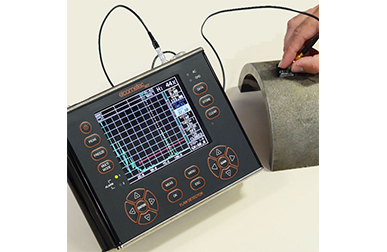

The Elcometer FD800 Bench Top Flaw Detector range combines state-of-the-art flaw detection with advanced material thickness capabilities.

- Summary

-

Summary

-

Designed for use in the laboratory these gauges are the tool you need for all your flaw detecting needs.

The Elcometer FD800 Bench Top Flaw Detector is available in two models: FD800DL and FD800DL+.

The time corrected gain (TCG) feature automatically compensates for sound attenuation through a material, further increasing the performance of the gauge.

Within the grid batching of the FD800DL+ the user has the capability to enter 'OBSTRUCT' on to the grid for easy identification of inaccessible locations to measure.

The FD800DL+ has a 6Gb internal memory and an external SD slot which allows up to 64Gb with full data logging via RS232 data output to ElcoMaster® data management software.

-

- Key Features

-

Key Features

FD800 Bench Top Flaw Detectors

Features:

- Blanview sunlight readable QVGA TFT colour display

- Sizing Toolkits: DAC, AWS, TCG, DGS

- Pulse Repetition Frequency: 8 to 333 Hz, adjustable

- Screen Refresh Rate: 60Hz

- Detection: Z-Cross, Flank & Peak

- Automatic: probe zero, probe recognition, and temperature compensation

- Measurement: Variety of modes to address a number of applications

- Large data storage: 6Gb internal & up to 64Gb external SD slot

- Multiple formats: Alpha numeric grid and sequential with auto identifier

- Up to 12 hours of battery life

- Download to ElcoMaster® data management software

-

- Product Features

-

Product FeaturesFD800 Bench Top Flaw Detectors

Display Mode Features Model & Part Number FD800+ & FD800DL+ Display Mode Material thickness digits display B-Scan cross sectional display B-Scan with digits display Scan bar display Coating thickness display A-Scan display + Rectified, - Rectified, Full Waveform (RF) Flaw Detection Modes TRIG, DAC, AWS, TCG, Zero Crossing, Flank, Peak Measurement Mode1 PE, PETP (Temp Compensation), EE (ThruPaint™), EEV, CT (Coating) & PECT Measurement Rate (Thickness Mode) Manual 4 readings per second Scan Mode 32 readings per second Scan bar display 6 readings per second Velocity Calibration Range 256 - 16,000m/s (0.0100 - 0.6300in/ms) Additional Features: Additional Features Differential Mode Limit alarm mode B-Scan display speed adjustable display speed Calibration setups 64 user-definable setups transferrable to and from a PC archive Gates 3 fully adjustable gates: start, stop, width & threshold Damping adjustable; impedance matching for optimising transducer performance Pulser type FD800DL: two adjustable square wave pulsers.

FD800DL+: two tone burst pulsersGain Manual, automatic gain control (AGC) with 110dB range with 0.2dB resolution Timing Precision TCXO timing with single shot 100 MHz 8 bit ultra-low power digitizer Data Logging •6Gb internal & up to 64Gb external SD slot

•Bitmap graphic capture

•sequential and grid logging

•Alpha numeric batch identification

•OBSTRUCT indicates inaccessible locationsCalibration Options single, two point, velocity, material type Transducer recognition Automatic V-path / dual path error correction Automatic Probe Zero Automatic Flaw Detection Product Features Automatic Calibration Longitudinal (straight), or Shear (angle) Probe Types Single Contact, Dual, Delay & Angle Material Velocity Table Contains longitudinal and shear velocities for a variety of material types TRIG Trigonometric display of beam path, depth, surface distance, and curved surface correction. Used with angle beam transducers DAC Up to 8 points may be entered and used to digitally draw a DAC curve. Reference -2, -6, -10, (-6/-12), (-6/-14), (-2/-6/-10) dB. Amplitude displayed in %DAC, dB, or %FSH AWS Automatic defect sizing in accordance with AWS D1.1 structural welding code. AVG/DGS Automatic defect sizing using probe data. Stores up to 64 custom setups TCG Time corrected gain. 50 dB dynamic range, 20 dB per microsecond, up to 8 points for curve definition Detection Modes Passage à zéro, Flanc et Pic Display Freeze Hold current waveform on screen Peak Memory Captures peak signal amplitude PRF 8 to 2000Hz in selectable steps (8, 16, 32, 66, 125, 250, 333, 1000, 2000Hz) Pulse Width 40 to 400 ns. Selectable step options 40, 80 & 400 ns (labeled spike, thin & wide) Frequency Bands FD800DL & FD800DL+: Broadband 1.8 - 19 MHz (-3dB). Four narrow bands at 1, 2, 5, 10MHz, FD800DL+: Additional narrow bands at 0.5MHz, 15MHz Horizontal Linearity +/- 0.4% FSW Vertical Linearity +/- 1% FSH Amplifier Linearity +/- 1 dB Amplitude Measurement 0 to 100% FSH, with 1% resolution Delay 0 - 999in (25,375mm) at steel velocity Display Blanview sunlight readable QVGA TFT colour display. 115.2 x 86.4mm (4.54 x 3.40 inches) viewable screen Display Refresh Rate 60Hz Units (selectable) mm or inches Backlight adjustable brightness Repeatability / Stability Indicator Battery Type 6 x AA Alkaline Low Battery Indicator Battery Save Mode Auto

-

- Technical Information

-

Technical SpecificationFD800 Bench Top Flaw Detectors

Part Number Description Certificate FD800DL+ FD800DL+ Bench Top Flaw Detector

FD800DL FD800DL Bench Top Flaw Detector

Measurement Accuracy1 ± 1% or ±0.1mm whichever is the greater Measuring Range2 Pulse Echo (PE) 0.63 - 30480mm (0.025 - 1,200") Pulse Echo Temp Comp (PETP) 0.63 - 30480mm (0.025 - 1,200") Echo Echo ThruPaint™ (EE) 1.27 - 102mm (0.050 - 4.0”) Echo Echo Verify (EEV) 1.27 - 25.4mm (0.050 - 1.0”) Coating Thickness (CT) 0.0127 - 2.54mm (0.0005 - 0.100”) Pulse Echo Coating Thickness (PECT) 0.63 - 30480mm (0.025 - 1,200") Pulse Echo Coating Thickness (PECT) 0.01 - 2.54mm (0.001 - 0.100”) Resolution 0.01mm (0.001”), 0.001mm (0.0001”) Operating Temperature -10 to 60ºC (14 to 140ºF) Battery Life (Approximate) 12 hours Weight (including batteries) 2.04kg (4.5lbs) Size (w x h x d) 216.0 x 165.0 x 70.0mm (8.5 x 6.5 x 2.5 inches) Case Design Aluminium case design with gasket sealed end caps, waterproof membrane keypad Transducer Connector Type LEMO RS232 Interface Packing List Elcometer NDT FD800DL or FD800DL+ gauge, couplant, carry case, user manual, test certificate, 6 x AA batteries, ElcoMaster® software, transfer cable ¹ PE: Pulse-Echo Mode, EE: Echo-Echo (ThruPaint™) Mode.

² Measuring range & accuracy depends on material, surface conditions and the transducer selected.

● Test Certificate supplied as standard.

-

- Downloads

-

Downloads

- Part Numbers

-

Part NumbersFD800 Bench Top Flaw DetectorsNo data found!!

-

FD800DL+ Bench Top Flaw Detector

FD800DL+ Bench Top Flaw Detector- Part Number : FD800DL+

-

FD800DL Bench Top Flaw Detector

FD800DL Bench Top Flaw Detector- Part Number : FD800DL

- Accessories

-

AccessoriesFD800 Bench Top Flaw Detectors

ElcoMaster®

It’s not all about taking readings, it’s what you do with them that counts - save up to 30% of your working week by producing professional reports in seconds with ElcoMaster® Software.

Part Number: TC-24034-1

Part Number: TC-24034-1 Part Number: TC-24034-2

Part Number: TC-24034-2 Part Number: TC-24034-3

Part Number: TC-24034-3 Part Number: TC-24034-9

Part Number: TC-24034-9 Part Number: TL-24030-1

Part Number: TL-24030-1 Part Number: TL-24030-2

Part Number: TL-24030-2 Part Number: TL-24030-3

Part Number: TL-24030-3 Part Number: TL-24030-5

Part Number: TL-24030-5 Part Number: TL-24030-6

Part Number: TL-24030-6 Part Number: TL-24030-7

Part Number: TL-24030-7 Part Number: TL-24031

Part Number: TL-24031 Part Number: TL-24032

Part Number: TL-24032 Part Number: TD-24033-1

Part Number: TD-24033-1 Part Number: TD-24033-2

Part Number: TD-24033-2 Part Number: TD-24033-3

Part Number: TD-24033-3 Part Number: TD-24033-4

Part Number: TD-24033-4 Part Number: TD-24033-5

Part Number: TD-24033-5 Part Number: TD-24033-6

Part Number: TD-24033-6 Part Number: TD-24033-7

Part Number: TD-24033-7 Part Number: TD-24033-8

Part Number: TD-24033-8 Part Number: TZ-24035

Part Number: TZ-24035

-

- Home

- NDT Equipment

- NDT Equipment

- Flaw Detection

- Ultrasonic Flaw Detectors

- FD800 Bench Top Flaw Detectors

FD800 Bench Top Flaw Detectors

The Elcometer FD800 Bench Top Flaw Detector range combines state-of-the-art flaw detection with advanced material thickness capabilities.

Summary

FD800 Bench Top Flaw Detectors

Designed for use in the laboratory these gauges are the tool you need for all your flaw detecting needs.

The Elcometer FD800 Bench Top Flaw Detector is available in two models: FD800DL and FD800DL+.

The time corrected gain (TCG) feature automatically compensates for sound attenuation through a material, further increasing the performance of the gauge.

Within the grid batching of the FD800DL+ the user has the capability to enter 'OBSTRUCT' on to the grid for easy identification of inaccessible locations to measure.

The FD800DL+ has a 6Gb internal memory and an external SD slot which allows up to 64Gb with full data logging via RS232 data output to ElcoMaster® data management software.

Key Features

FD800 Bench Top Flaw Detectors

Features:

- Blanview sunlight readable QVGA TFT colour display

- Sizing Toolkits: DAC, AWS, TCG, DGS

- Pulse Repetition Frequency: 8 to 333 Hz, adjustable

- Screen Refresh Rate: 60Hz

- Detection: Z-Cross, Flank & Peak

- Automatic: probe zero, probe recognition, and temperature compensation

- Measurement: Variety of modes to address a number of applications

- Large data storage: 6Gb internal & up to 64Gb external SD slot

- Multiple formats: Alpha numeric grid and sequential with auto identifier

- Up to 12 hours of battery life

- Download to ElcoMaster® data management software

Product FeaturesFD800 Bench Top Flaw DetectorsDisplay Mode Features Model & Part Number FD800+ & FD800DL+ Display Mode Material thickness digits display B-Scan cross sectional display B-Scan with digits display Scan bar display Coating thickness display A-Scan display + Rectified, - Rectified, Full Waveform (RF) Flaw Detection Modes TRIG, DAC, AWS, TCG, Zero Crossing, Flank, Peak Measurement Mode1 PE, PETP (Temp Compensation), EE (ThruPaint™), EEV, CT (Coating) & PECT Measurement Rate (Thickness Mode) Manual 4 readings per second Scan Mode 32 readings per second Scan bar display 6 readings per second Velocity Calibration Range 256 - 16,000m/s (0.0100 - 0.6300in/ms) Additional Features: Additional Features Differential Mode Limit alarm mode B-Scan display speed adjustable display speed Calibration setups 64 user-definable setups transferrable to and from a PC archive Gates 3 fully adjustable gates: start, stop, width & threshold Damping adjustable; impedance matching for optimising transducer performance Pulser type FD800DL: two adjustable square wave pulsers.

FD800DL+: two tone burst pulsersGain Manual, automatic gain control (AGC) with 110dB range with 0.2dB resolution Timing Precision TCXO timing with single shot 100 MHz 8 bit ultra-low power digitizer Data Logging •6Gb internal & up to 64Gb external SD slot

•Bitmap graphic capture

•sequential and grid logging

•Alpha numeric batch identification

•OBSTRUCT indicates inaccessible locationsCalibration Options single, two point, velocity, material type Transducer recognition Automatic V-path / dual path error correction Automatic Probe Zero Automatic Flaw Detection Product Features Automatic Calibration Longitudinal (straight), or Shear (angle) Probe Types Single Contact, Dual, Delay & Angle Material Velocity Table Contains longitudinal and shear velocities for a variety of material types TRIG Trigonometric display of beam path, depth, surface distance, and curved surface correction. Used with angle beam transducers DAC Up to 8 points may be entered and used to digitally draw a DAC curve. Reference -2, -6, -10, (-6/-12), (-6/-14), (-2/-6/-10) dB. Amplitude displayed in %DAC, dB, or %FSH AWS Automatic defect sizing in accordance with AWS D1.1 structural welding code. AVG/DGS Automatic defect sizing using probe data. Stores up to 64 custom setups TCG Time corrected gain. 50 dB dynamic range, 20 dB per microsecond, up to 8 points for curve definition Detection Modes Passage à zéro, Flanc et Pic Display Freeze Hold current waveform on screen Peak Memory Captures peak signal amplitude PRF 8 to 2000Hz in selectable steps (8, 16, 32, 66, 125, 250, 333, 1000, 2000Hz) Pulse Width 40 to 400 ns. Selectable step options 40, 80 & 400 ns (labeled spike, thin & wide) Frequency Bands FD800DL & FD800DL+: Broadband 1.8 - 19 MHz (-3dB). Four narrow bands at 1, 2, 5, 10MHz, FD800DL+: Additional narrow bands at 0.5MHz, 15MHz Horizontal Linearity +/- 0.4% FSW Vertical Linearity +/- 1% FSH Amplifier Linearity +/- 1 dB Amplitude Measurement 0 to 100% FSH, with 1% resolution Delay 0 - 999in (25,375mm) at steel velocity Display Blanview sunlight readable QVGA TFT colour display. 115.2 x 86.4mm (4.54 x 3.40 inches) viewable screen Display Refresh Rate 60Hz Units (selectable) mm or inches Backlight adjustable brightness Repeatability / Stability Indicator Battery Type 6 x AA Alkaline Low Battery Indicator Battery Save Mode Auto Technical SpecificationFD800 Bench Top Flaw DetectorsPart Number Description Certificate FD800DL+ FD800DL+ Bench Top Flaw Detector

FD800DL FD800DL Bench Top Flaw Detector

Measurement Accuracy1 ± 1% or ±0.1mm whichever is the greater Measuring Range2 Pulse Echo (PE) 0.63 - 30480mm (0.025 - 1,200") Pulse Echo Temp Comp (PETP) 0.63 - 30480mm (0.025 - 1,200") Echo Echo ThruPaint™ (EE) 1.27 - 102mm (0.050 - 4.0”) Echo Echo Verify (EEV) 1.27 - 25.4mm (0.050 - 1.0”) Coating Thickness (CT) 0.0127 - 2.54mm (0.0005 - 0.100”) Pulse Echo Coating Thickness (PECT) 0.63 - 30480mm (0.025 - 1,200") Pulse Echo Coating Thickness (PECT) 0.01 - 2.54mm (0.001 - 0.100”) Resolution 0.01mm (0.001”), 0.001mm (0.0001”) Operating Temperature -10 to 60ºC (14 to 140ºF) Battery Life (Approximate) 12 hours Weight (including batteries) 2.04kg (4.5lbs) Size (w x h x d) 216.0 x 165.0 x 70.0mm (8.5 x 6.5 x 2.5 inches) Case Design Aluminium case design with gasket sealed end caps, waterproof membrane keypad Transducer Connector Type LEMO RS232 Interface Packing List Elcometer NDT FD800DL or FD800DL+ gauge, couplant, carry case, user manual, test certificate, 6 x AA batteries, ElcoMaster® software, transfer cable ¹ PE: Pulse-Echo Mode, EE: Echo-Echo (ThruPaint™) Mode.

² Measuring range & accuracy depends on material, surface conditions and the transducer selected.

● Test Certificate supplied as standard.Part NumbersFD800 Bench Top Flaw DetectorsNo data found!!-

FD800DL+ Bench Top Flaw Detector

FD800DL+ Bench Top Flaw Detector- Part Number : FD800DL+

-

FD800DL Bench Top Flaw Detector

FD800DL Bench Top Flaw Detector- Part Number : FD800DL

AccessoriesFD800 Bench Top Flaw DetectorsElcoMaster®

It’s not all about taking readings, it’s what you do with them that counts - save up to 30% of your working week by producing professional reports in seconds with ElcoMaster® Software.

Part Number: TC-24034-1

Part Number: TC-24034-1 Part Number: TC-24034-2

Part Number: TC-24034-2 Part Number: TC-24034-3

Part Number: TC-24034-3 Part Number: TC-24034-9

Part Number: TC-24034-9 Part Number: TL-24030-1

Part Number: TL-24030-1 Part Number: TL-24030-2

Part Number: TL-24030-2 Part Number: TL-24030-3

Part Number: TL-24030-3 Part Number: TL-24030-5

Part Number: TL-24030-5 Part Number: TL-24030-6

Part Number: TL-24030-6 Part Number: TL-24030-7

Part Number: TL-24030-7 Part Number: TL-24031

Part Number: TL-24031 Part Number: TL-24032

Part Number: TL-24032 Part Number: TD-24033-1

Part Number: TD-24033-1 Part Number: TD-24033-2

Part Number: TD-24033-2 Part Number: TD-24033-3

Part Number: TD-24033-3 Part Number: TD-24033-4

Part Number: TD-24033-4 Part Number: TD-24033-5

Part Number: TD-24033-5 Part Number: TD-24033-6

Part Number: TD-24033-6 Part Number: TD-24033-7

Part Number: TD-24033-7 Part Number: TD-24033-8

Part Number: TD-24033-8 Part Number: TZ-24035

Part Number: TZ-24035

- Part Numbers

-