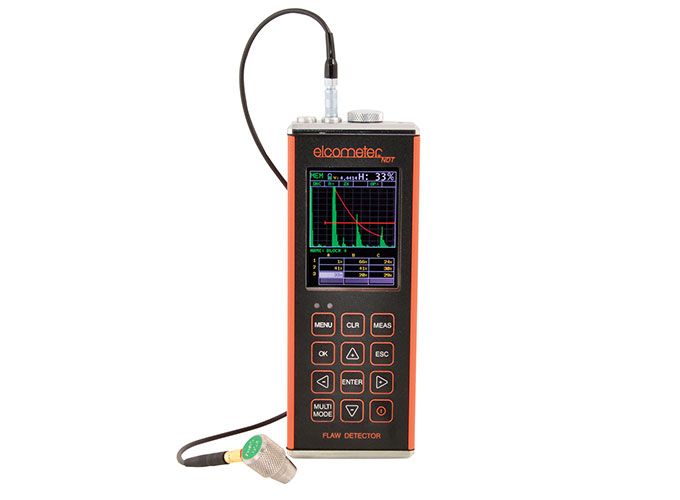

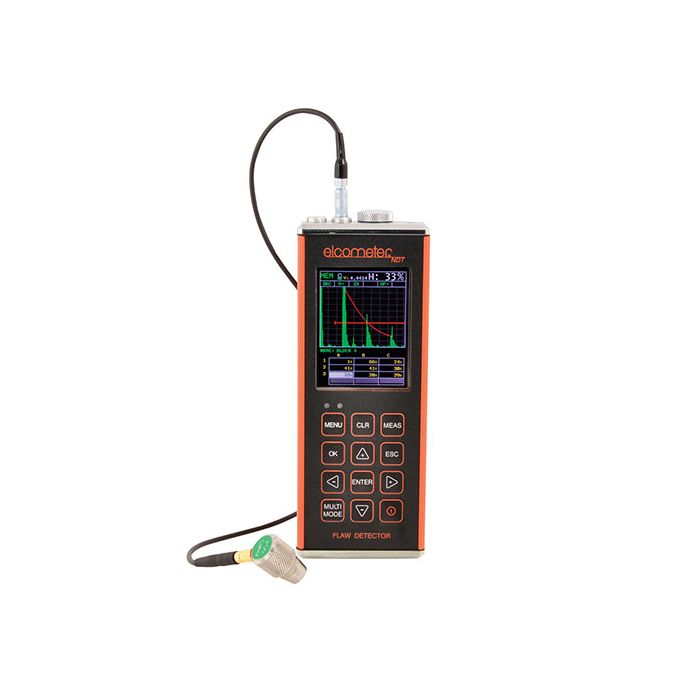

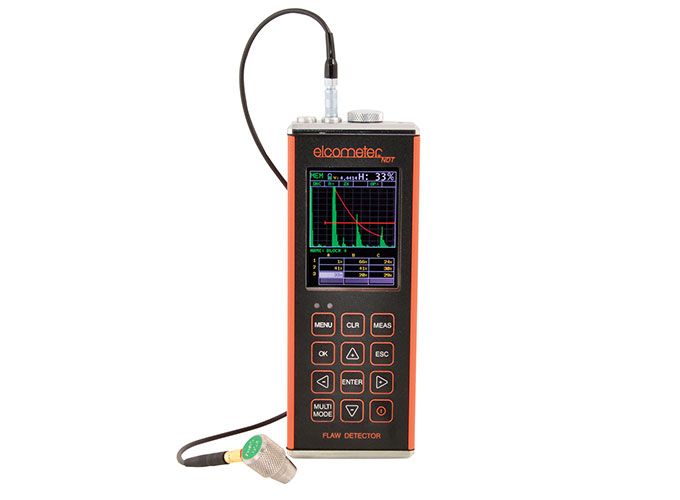

Elcometer FD700 Mini Flaw Detectors

The hand-held FD700 Flaw Detector range combines state-of-the-art flaw detection with advanced material thickness capabilities.

- Summary

-

Summary

-

Versatile

Two gauges in one

The FD700 series has two functions, a thickness gauge and a flaw detector.

When the FD700 is set to thickness gauge it has the ability to measure coatings and material thickness simultaneously. When set to flaw detector the gauge has the ability to detect the size and position of flaws and to differentiate between flaw types in various materials and welded joints.

Intelligent

User definable limits for pass/fail indication

Set hi/lo limits for pass/fail indication with audible warnings and built-in differential mode for quality control inspections.

Powerful

Store each measurement for further analysis

Up to 4GB of readings can be saved into the gauge memory as each measurement is taken, which can be downloaded later into an inspection application or into ElcoMaster® Software for further analysis and reporting.

Customisable

Customistable tool kits and reading display

The FD700 has a choice of display modes allowing the user to select the most

appropriate for their needs; from A & B-Scan displays to flaw detection modes

such as TRIG, DAC, TCG, Flank and Peak.The Elcometer FD700 Mini Flaw Detector is available in two models: FD700+ and FD700DL+.

Whether you are on-site or in the laboratory these gauges are the tool you need for all your flaw detecting needs.

The time corrected gain (TCG) feature automatically compensates for sound attenuation through a material, further increasing the performance of the gauge.

The FD700DL+ stores up to 4GB worth of readings with A/B-scan images in alpha numeric batches with full data logging and firmware updates via USB data output to ElcoMaster® data management software.

Features:

- Exceptional visibility in sunlight (AMOLED)

- colour VGA display (320x240 pixels)

- Sizing Toolkits: DAC, AWS, TCG, DGS

- Pulse Repetition Frequency: 8 to 2000Hz, adjustable

- Detection: Z-Cross, Flank & Peak

- Automatic: probe zero, probe recognition, and temperature compensation

- Measurement: Variety of modes to address a number of applications

- Large data storage with multiple formats: Alpha numeric grid and sequential with auto identifier

- Download to ElcoMaster® data management software

-

- Key Features

-

Key Features

Elcometer FD700 Mini Flaw Detectors

Detection Methods

Zero Crossing:

The gate detects the flank of the pulse, but the measurement is taken at the next crossing of the x axis. This is the most common type of detect in ultrasonic measurement.

Flank:

The gate is triggered by the flank (or side) of the pulse on the graph and the measurement taken at this exact point.

Peak:

The gate is triggered by the intersection with the A-scan pulse and the detection is taken from the next peak in the signal (when it stops rising and starts falling).

TRIG:

TRIG enabling location of flaws in both surface distance and depth. Trigonometric display of beam path, depth, surface distance, and curved surface correction. Used with angle beam transducers.

DAC:

Distance amplitude correction for the creation of DAC curves which are used to inform the operator of the size of any given flaw at any depth.

AWS:

The American Weld Standard function provides automatic defect sizing in accordance with AWS D1.1 structural welding code.

TCG:

Time corrected gain increases gain as distance increases, in order to achieve an over all level of sensitivity for the same flaw/reflector at different distances.

-

- Product Features

-

Product FeaturesElcometer FD700 Mini Flaw Detectors

Material Thickness Features Model & Part Number FD700+ & FD700DL+ Display Mode Material thickness digits display B-Scan cross sectional display B-Scan with digits display Scan bar display Coating thickness display A-Scan display + Rectified, - Rectified, Full Waveform (RF) Flaw Detection Modes TRIG, DAC, AWS, TCG, AVG/DGS Measurement mode PE, PETP (Temp Compensation), EE (ThruPaint™), EEV, CT (Coating), PECT Measurement Rate (Thickness Mode) Manual 8 readings per second Scan Mode 50 readings per second Scan bar display 10 readings per second Additional Features: Additional Features Differential Mode Limit alarm mode B-Scan display speed adjustable display speed Calibration setups 64 user-definable setups transferrable to and from a PC archive Gates 2 (flaw) and 3 (thickness) adjustable gates: start, stop, width & threshold Damping 50, 75, 100, 300, 600, & 1500 ohms Pulser type Two adjustable square wave pulsers and receivers Gain Manual, automatic gain control (AGC) with 110dB range with 0.2dB resolution Timing Precision TCXO timing with single shot 100 MHz 8 bit ultra-low power digitizer Memory and Data Logging 4GB internal memory

Sequential and grid logging

Alpha numeric batch identification

OBSTRUCT indicates inaccessible locations

Bitmap graphic captureCalibration Options single, two point, velocity, material type Transducer recognition Automatic V-path / dual path error correction Automatic Flaw Detection Product Features Automatic Calibration Longitudinal (straight), or Shear (angle) Probe Types Single Contact, Dual, Delay & Angle Material Velocity Table Contains longitudinal and shear velocities for a variety of material types TRIG Trigonometric display of beam path, depth, surface distance, and curved surface correction. Used with angle beam transducers DAC Up to 8 points may be entered and used to digitally draw a DAC curve. Reference -2, -6, -10, (-6/-12), (-6/-14), (-2/-6/-10) dB. Amplitude displayed in %DAC, dB, or %FSH AWS Automatic defect sizing in accordance with AWS D1.1 structural welding code. AVG/DGS Automatic defect sizing using probe data. Stores up to 64 custom setups TCG Time corrected gain. 50 dB dynamic range, 20 dB per microsecond, up to 8 points for curve definition Detection Modes Passage à zéro, Flanc et Pic Display Freeze Hold current waveform on screen Peak Memory Captures peak signal amplitude PRF 8 to 2000Hz in selectable steps (8, 16, 32, 66, 125, 250, 333, 1000, 2000Hz) Skip Bar Displays skip legs in the waveform area Pulse Width 40 to 400 ns. Selectable step options 40, 80 & 400 ns (labeled spike, thin & wide) Frequency Bands FD700+ & FD700DL+: Broadband 1.8 - 19MHz (-3dB)

FD700DL+: Three narrow bands at 2MHz, 5MHz, 10MHzHorizontal Linearity +/- 0.4% FSW Vertical Linearity +/- 1% FSH Amplifier Linearity +/- 1 dB Amplitude Measurement 0 to 100% FSH, with 1% resolution Delay 0 - 999in (25,375mm) at steel velocity Display 1/4 VGA AMOLED colour display 57.6 x 43.2mm (2.27 x 1.78”) viewable area Display Refresh Rate 60Hz Units (selectable) mm or inches Backlight adjustable brightness Repeatability / Stability Indicator Low Battery Indicator Battery Save Mode Auto

-

- Technical Information

-

Technical SpecificationElcometer FD700 Mini Flaw Detectors

Part Number Description Certificate FD700+ Elcometer FD700+ Mini Flaw Detector

FD700DL+ Elcometer FD700DL+ Mini Flaw Detector

Transducer Probe Type Single & Dual Element Thickness Gauge: Measurement Range1 Pulse Echo (PE) 0.63 - 2,440mm (0.025 – 96”) Pulse Echo (single contact) 1.0 - 30,480mm (0.040 - 1200”) Echo Echo ThruPaint™ (EE) 1.27 - 102mm (0.050 - 4.0”) Echo Echo (single delay line) 0.178 - 25.4mm (0.007 -1.00”) Echo Echo (single contact) 1.0 - 3,050mm (0.040 - 120”) Echo Echo Verify (EEV) 1.27 - 25.4mm (0.050 - 1.0”) Pulse Echo Temp Comp (PETP) 0.63 - 2,440mm (0.025 – 96”) Coating Thickness (CT) 0.0127 - 2.54mm (0.0005 - 0.100”) Pulse Echo Coating Thickness (PECT) 54mm (0.001 - 0.100”) Pulse Echo Coating Thickness (PECT) 0,63 - 2.440mm (0,025 – 96”) Measurement Accuracy1 0.01mm (0.001”) Resolution 0.01mm (0.001”), 0.001mm (0.0001”) Memory 4GB internal memory Operating Temperature -10 to 60ºC (14 to 140ºF) Data Output USB Power Supply 3 x AA batteries and via USB Battery Life2 Alkaline (12hrs), Nicad (5hrs), and NI-MH (12hrs) Gauge Weight 397g (14oz) - including batteries Gauge Dimensions 63.5 x 165 x 31.5mm (2.5 x 6.5 x 1.24”) Packing List Elcometer NDT FD700 gauge, couplant, carry case, user manual, test certificate, 3 x AA batteries, ElcoMaster® Software, transfer cable 1Measuring range & accuracy depends on material, surface conditions and the transducer selected

2Approximate battery life, when in continuous measurement mode.

● Test Certificate supplied as standard.

-

- Standards

-

StandardsElcometer FD700 Mini Flaw Detectors

ASTM E 797, EN 14127, EN 15317

-

- Downloads

-

Downloads

- Part Numbers

-

Part NumbersElcometer FD700 Mini Flaw DetectorsNo data found!!

-

Elcometer FD700+ Mini Flaw Detector

Elcometer FD700+ Mini Flaw Detector- Measurement Accuracy1: 0.01mm (0.001”)

- Part Number : FD700+

-

Elcometer FD700DL+ Mini Flaw Detector

Elcometer FD700DL+ Mini Flaw Detector- Measurement Accuracy1: 0.01mm (0.001”)

- Part Number : FD700DL+

- Accessories

-

AccessoriesElcometer FD700 Mini Flaw Detectors

Part Number: TC-24034-1

Part Number: TC-24034-1 Part Number: TC-24034-2

Part Number: TC-24034-2 Part Number: TC-24034-3

Part Number: TC-24034-3 Part Number: TC-24034-9

Part Number: TC-24034-9 Part Number: TL-24030-1

Part Number: TL-24030-1 Part Number: TL-24030-2

Part Number: TL-24030-2 Part Number: TL-24030-3

Part Number: TL-24030-3 Part Number: TL-24030-5

Part Number: TL-24030-5 Part Number: TL-24030-6

Part Number: TL-24030-6 Part Number: TL-24030-7

Part Number: TL-24030-7 Part Number: TL-24031

Part Number: TL-24031 Part Number: TL-24032

Part Number: TL-24032 Part Number: TD-24033-1

Part Number: TD-24033-1 Part Number: TD-24033-2

Part Number: TD-24033-2 Part Number: TD-24033-3

Part Number: TD-24033-3 Part Number: TD-24033-4

Part Number: TD-24033-4 Part Number: TD-24033-5

Part Number: TD-24033-5 Part Number: TD-24033-6

Part Number: TD-24033-6 Part Number: TD-24033-7

Part Number: TD-24033-7 Part Number: TD-24033-8

Part Number: TD-24033-8 Part Number: TZ-24035

Part Number: TZ-24035

Welcome to Elcometer.tv

Your ultimate training channel

- Home

- Elcometer FD700 Mini Flaw Detectors

Elcometer FD700 Mini Flaw Detectors

The hand-held FD700 Flaw Detector range combines state-of-the-art flaw detection with advanced material thickness capabilities.

Versatile

Two gauges in one

The FD700 series has two functions, a thickness gauge and a flaw detector.

When the FD700 is set to thickness gauge it has the ability to measure coatings and material thickness simultaneously. When set to flaw detector the gauge has the ability to detect the size and position of flaws and to differentiate between flaw types in various materials and welded joints.

Intelligent

User definable limits for pass/fail indication

Set hi/lo limits for pass/fail indication with audible warnings and built-in differential mode for quality control inspections.

Powerful

Store each measurement for further analysis

Up to 4GB of readings can be saved into the gauge memory as each measurement is taken, which can be downloaded later into an inspection application or into ElcoMaster® Software for further analysis and reporting.

Customisable

Customistable tool kits and reading display

The FD700 has a choice of display modes allowing the user to select the most

appropriate for their needs; from A & B-Scan displays to flaw detection modes

such as TRIG, DAC, TCG, Flank and Peak.Summary

Elcometer FD700 Mini Flaw Detectors

The Elcometer FD700 Mini Flaw Detector is available in two models: FD700+ and FD700DL+.

Whether you are on-site or in the laboratory these gauges are the tool you need for all your flaw detecting needs.

The time corrected gain (TCG) feature automatically compensates for sound attenuation through a material, further increasing the performance of the gauge.

The FD700DL+ stores up to 4GB worth of readings with A/B-scan images in alpha numeric batches with full data logging and firmware updates via USB data output to ElcoMaster® data management software.

Features:

- Exceptional visibility in sunlight (AMOLED)

- colour VGA display (320x240 pixels)

- Sizing Toolkits: DAC, AWS, TCG, DGS

- Pulse Repetition Frequency: 8 to 2000Hz, adjustable

- Detection: Z-Cross, Flank & Peak

- Automatic: probe zero, probe recognition, and temperature compensation

- Measurement: Variety of modes to address a number of applications

- Large data storage with multiple formats: Alpha numeric grid and sequential with auto identifier

- Download to ElcoMaster® data management software

Key Features

Elcometer FD700 Mini Flaw Detectors

Detection Methods

Zero Crossing:

The gate detects the flank of the pulse, but the measurement is taken at the next crossing of the x axis. This is the most common type of detect in ultrasonic measurement.

Flank:

The gate is triggered by the flank (or side) of the pulse on the graph and the measurement taken at this exact point.

Peak:

The gate is triggered by the intersection with the A-scan pulse and the detection is taken from the next peak in the signal (when it stops rising and starts falling).

TRIG:

TRIG enabling location of flaws in both surface distance and depth. Trigonometric display of beam path, depth, surface distance, and curved surface correction. Used with angle beam transducers.

DAC:

Distance amplitude correction for the creation of DAC curves which are used to inform the operator of the size of any given flaw at any depth.

AWS:

The American Weld Standard function provides automatic defect sizing in accordance with AWS D1.1 structural welding code.

TCG:

Time corrected gain increases gain as distance increases, in order to achieve an over all level of sensitivity for the same flaw/reflector at different distances.

Product FeaturesElcometer FD700 Mini Flaw DetectorsMaterial Thickness Features Model & Part Number FD700+ & FD700DL+ Display Mode Material thickness digits display B-Scan cross sectional display B-Scan with digits display Scan bar display Coating thickness display A-Scan display + Rectified, - Rectified, Full Waveform (RF) Flaw Detection Modes TRIG, DAC, AWS, TCG, AVG/DGS Measurement mode PE, PETP (Temp Compensation), EE (ThruPaint™), EEV, CT (Coating), PECT Measurement Rate (Thickness Mode) Manual 8 readings per second Scan Mode 50 readings per second Scan bar display 10 readings per second Additional Features: Additional Features Differential Mode Limit alarm mode B-Scan display speed adjustable display speed Calibration setups 64 user-definable setups transferrable to and from a PC archive Gates 2 (flaw) and 3 (thickness) adjustable gates: start, stop, width & threshold Damping 50, 75, 100, 300, 600, & 1500 ohms Pulser type Two adjustable square wave pulsers and receivers Gain Manual, automatic gain control (AGC) with 110dB range with 0.2dB resolution Timing Precision TCXO timing with single shot 100 MHz 8 bit ultra-low power digitizer Memory and Data Logging 4GB internal memory

Sequential and grid logging

Alpha numeric batch identification

OBSTRUCT indicates inaccessible locations

Bitmap graphic captureCalibration Options single, two point, velocity, material type Transducer recognition Automatic V-path / dual path error correction Automatic Flaw Detection Product Features Automatic Calibration Longitudinal (straight), or Shear (angle) Probe Types Single Contact, Dual, Delay & Angle Material Velocity Table Contains longitudinal and shear velocities for a variety of material types TRIG Trigonometric display of beam path, depth, surface distance, and curved surface correction. Used with angle beam transducers DAC Up to 8 points may be entered and used to digitally draw a DAC curve. Reference -2, -6, -10, (-6/-12), (-6/-14), (-2/-6/-10) dB. Amplitude displayed in %DAC, dB, or %FSH AWS Automatic defect sizing in accordance with AWS D1.1 structural welding code. AVG/DGS Automatic defect sizing using probe data. Stores up to 64 custom setups TCG Time corrected gain. 50 dB dynamic range, 20 dB per microsecond, up to 8 points for curve definition Detection Modes Passage à zéro, Flanc et Pic Display Freeze Hold current waveform on screen Peak Memory Captures peak signal amplitude PRF 8 to 2000Hz in selectable steps (8, 16, 32, 66, 125, 250, 333, 1000, 2000Hz) Skip Bar Displays skip legs in the waveform area Pulse Width 40 to 400 ns. Selectable step options 40, 80 & 400 ns (labeled spike, thin & wide) Frequency Bands FD700+ & FD700DL+: Broadband 1.8 - 19MHz (-3dB)

FD700DL+: Three narrow bands at 2MHz, 5MHz, 10MHzHorizontal Linearity +/- 0.4% FSW Vertical Linearity +/- 1% FSH Amplifier Linearity +/- 1 dB Amplitude Measurement 0 to 100% FSH, with 1% resolution Delay 0 - 999in (25,375mm) at steel velocity Display 1/4 VGA AMOLED colour display 57.6 x 43.2mm (2.27 x 1.78”) viewable area Display Refresh Rate 60Hz Units (selectable) mm or inches Backlight adjustable brightness Repeatability / Stability Indicator Low Battery Indicator Battery Save Mode Auto Technical SpecificationElcometer FD700 Mini Flaw DetectorsPart Number Description Certificate FD700+ Elcometer FD700+ Mini Flaw Detector

FD700DL+ Elcometer FD700DL+ Mini Flaw Detector

Transducer Probe Type Single & Dual Element Thickness Gauge: Measurement Range1 Pulse Echo (PE) 0.63 - 2,440mm (0.025 – 96”) Pulse Echo (single contact) 1.0 - 30,480mm (0.040 - 1200”) Echo Echo ThruPaint™ (EE) 1.27 - 102mm (0.050 - 4.0”) Echo Echo (single delay line) 0.178 - 25.4mm (0.007 -1.00”) Echo Echo (single contact) 1.0 - 3,050mm (0.040 - 120”) Echo Echo Verify (EEV) 1.27 - 25.4mm (0.050 - 1.0”) Pulse Echo Temp Comp (PETP) 0.63 - 2,440mm (0.025 – 96”) Coating Thickness (CT) 0.0127 - 2.54mm (0.0005 - 0.100”) Pulse Echo Coating Thickness (PECT) 54mm (0.001 - 0.100”) Pulse Echo Coating Thickness (PECT) 0,63 - 2.440mm (0,025 – 96”) Measurement Accuracy1 0.01mm (0.001”) Resolution 0.01mm (0.001”), 0.001mm (0.0001”) Memory 4GB internal memory Operating Temperature -10 to 60ºC (14 to 140ºF) Data Output USB Power Supply 3 x AA batteries and via USB Battery Life2 Alkaline (12hrs), Nicad (5hrs), and NI-MH (12hrs) Gauge Weight 397g (14oz) - including batteries Gauge Dimensions 63.5 x 165 x 31.5mm (2.5 x 6.5 x 1.24”) Packing List Elcometer NDT FD700 gauge, couplant, carry case, user manual, test certificate, 3 x AA batteries, ElcoMaster® Software, transfer cable 1Measuring range & accuracy depends on material, surface conditions and the transducer selected

2Approximate battery life, when in continuous measurement mode.

● Test Certificate supplied as standard.Part NumbersElcometer FD700 Mini Flaw DetectorsNo data found!!-

Elcometer FD700+ Mini Flaw Detector

Elcometer FD700+ Mini Flaw Detector- Measurement Accuracy1: 0.01mm (0.001”)

- Part Number : FD700+

-

Elcometer FD700DL+ Mini Flaw Detector

Elcometer FD700DL+ Mini Flaw Detector- Measurement Accuracy1: 0.01mm (0.001”)

- Part Number : FD700DL+

Welcome to Elcometer.tv

Your ultimate training channelAccessoriesElcometer FD700 Mini Flaw Detectors Part Number: TC-24034-1

Part Number: TC-24034-1 Part Number: TC-24034-2

Part Number: TC-24034-2 Part Number: TC-24034-3

Part Number: TC-24034-3 Part Number: TC-24034-9

Part Number: TC-24034-9 Part Number: TL-24030-1

Part Number: TL-24030-1 Part Number: TL-24030-2

Part Number: TL-24030-2 Part Number: TL-24030-3

Part Number: TL-24030-3 Part Number: TL-24030-5

Part Number: TL-24030-5 Part Number: TL-24030-6

Part Number: TL-24030-6 Part Number: TL-24030-7

Part Number: TL-24030-7 Part Number: TL-24031

Part Number: TL-24031 Part Number: TL-24032

Part Number: TL-24032 Part Number: TD-24033-1

Part Number: TD-24033-1 Part Number: TD-24033-2

Part Number: TD-24033-2 Part Number: TD-24033-3

Part Number: TD-24033-3 Part Number: TD-24033-4

Part Number: TD-24033-4 Part Number: TD-24033-5

Part Number: TD-24033-5 Part Number: TD-24033-6

Part Number: TD-24033-6 Part Number: TD-24033-7

Part Number: TD-24033-7 Part Number: TD-24033-8

Part Number: TD-24033-8 Part Number: TZ-24035

Part Number: TZ-24035

- Part Numbers

-