Elcometer 224 Digital Surface Profile Gauge

- Protective Coatings

The Elcometer 224 Digital Surface Profile Gauge provides the very latest in surface profile measuring technology for measuring surface profile on either flat or curved surfaces.

- Summary

-

Summary

-

Accurate Surface Profile Measurements

- Can be used in accordance with National and International Standards

- Temperature stable measurements

- Statistics are calculated and displayed in real time during inspection

- Live and batch readings graph format for instant analysis

- Measurement capability to ±5%

A Powerful Surface Profile Gauge

- User replaceable tough tungsten carbide tip, can be used for up to 20,000 surface profile readings

- USB and Bluetooth® data output to iPhone¹ or Android™ devices

- Measures surface profiles up to 500μm (20mils)

- Review batch data or last 20 readings in a graph format

- Integral & separate probe options for flat and convex² curved surface

Efficient Inspections

- Fast reading rate of 50+ per minute

- Integral and separate probe versions to suit your application

- Alpha numeric batch identification

- Compatible with ElcoMaster® software and ElcoMaster® Mobile App

- Powersave Mode with tap awake

-

Fast and reliable peak-to-valley surface profile measurement

-

Accurately measure surface profile on flat or curved surfaces up to 500μm (20mils)

-

Measures both average peak-to-valley and average maximum peak-to-valley height

-

Portable, rugged hand-held design is ideal for field use

The Elcometer 224 surface profile meter is available in two different models: Model B and Model T. Each surface profile meter provides the user with increasing functionality - from the entry level Elcometer 224 Model B Surface Profile Gauge, to the top of the range Elcometer 224 Model T Surface Profile Gauge, with memory, alpha-numeric batching and Bluetooth® communication.

Standard and armoured probes are available for the separate models, providing even greater measurement flexibility. Elcometer surface profile probes are supplied with a glass zero plate, calibration test foils (nominal values 125µm (5.0mils) & 500µm (20mils)) and an Elcometer Test Certificate.ElcoMaster® Data Management Software

Inspectors can spend up to 30% of their working week producing reports. ElcoMaster® Software saves time and money by producing professional bespoke reports - even when out on site.

-

- Key Features

-

Key Features

Elcometer 224 Digital Surface Profile Gauge

User Friendly Gauge

- Large buttons ideal for gloved hands

- Easy to use menus in multiple languages

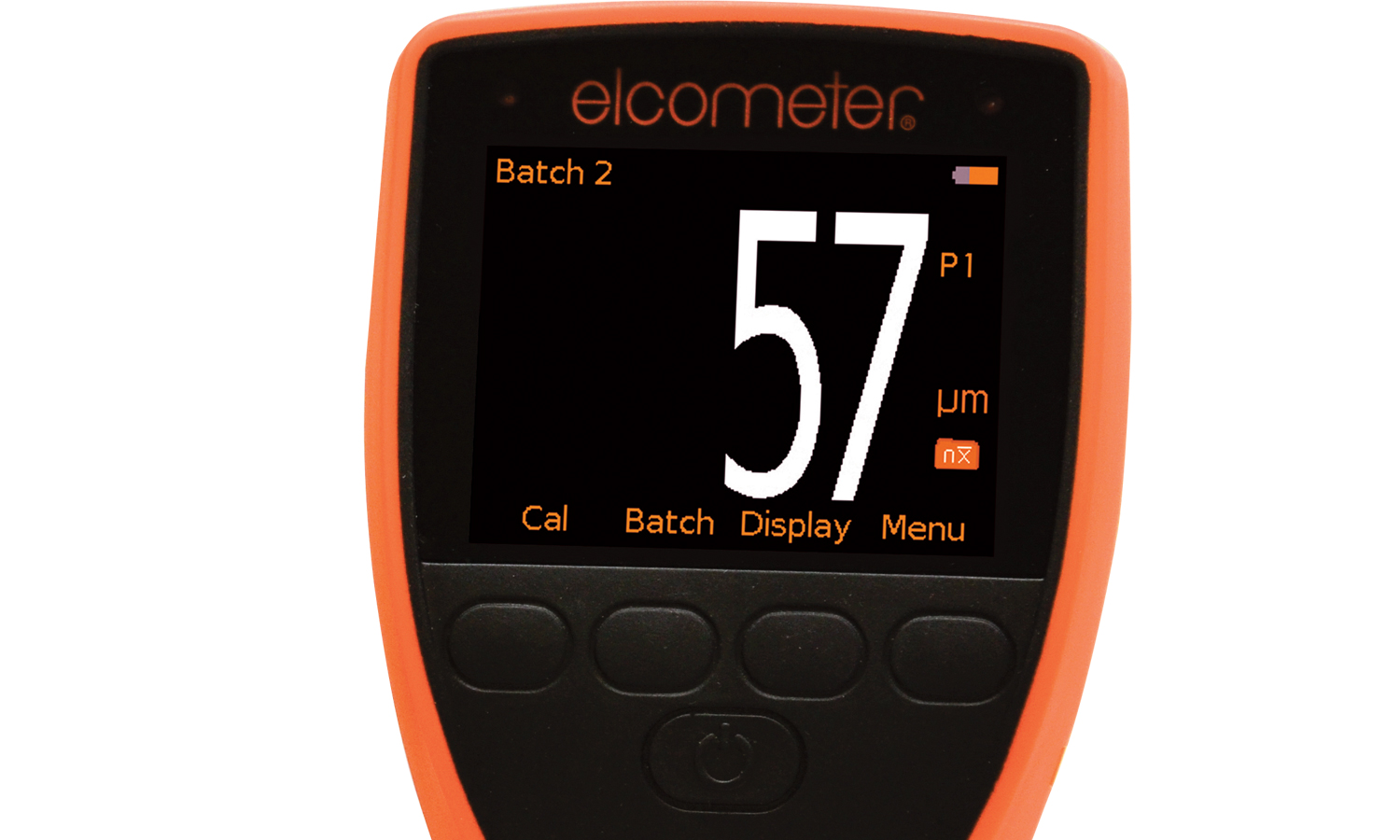

- High contrast colour LCD with auto rotate

- High and low reading limit indicators

- Factory calibrated for immediate use

Durability in Tough Environments

- Sealed, heavy duty and impact resistant

- Dust and waterproof equivalent to IP64

- Suitable for use in harsh environments

- Scratch and solvent resistant display

- Durable gauge and probe construction

A Reliable Surface Profile Gauge

- Repeatable and reproducible profile measurements

- 2 year gauge warranty³

- Supplied with fully traceable Test Certificates

- Batch & individual readings are date and time stamped

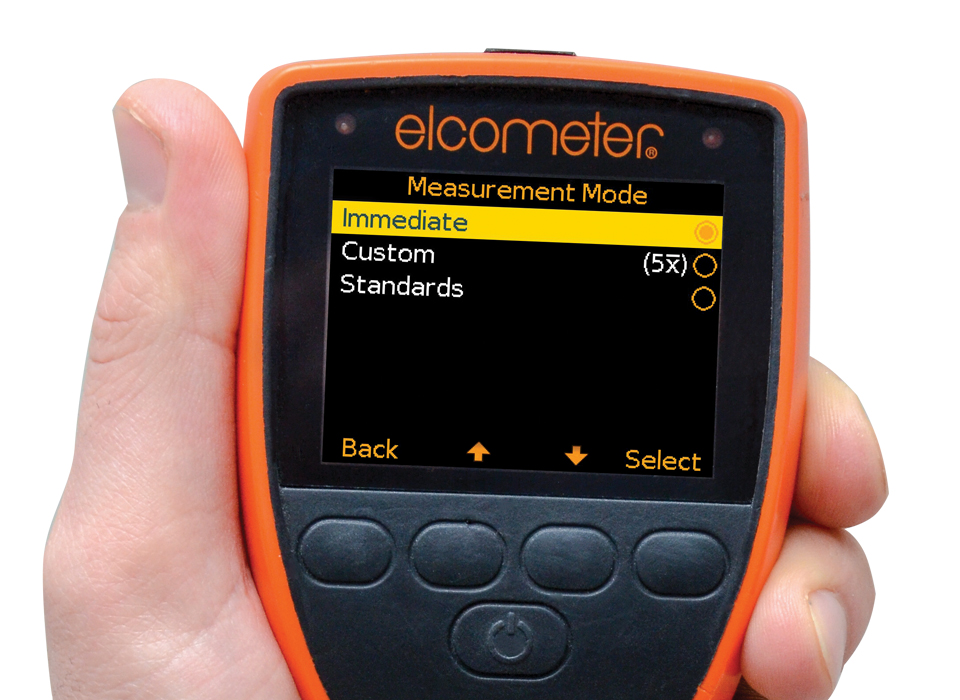

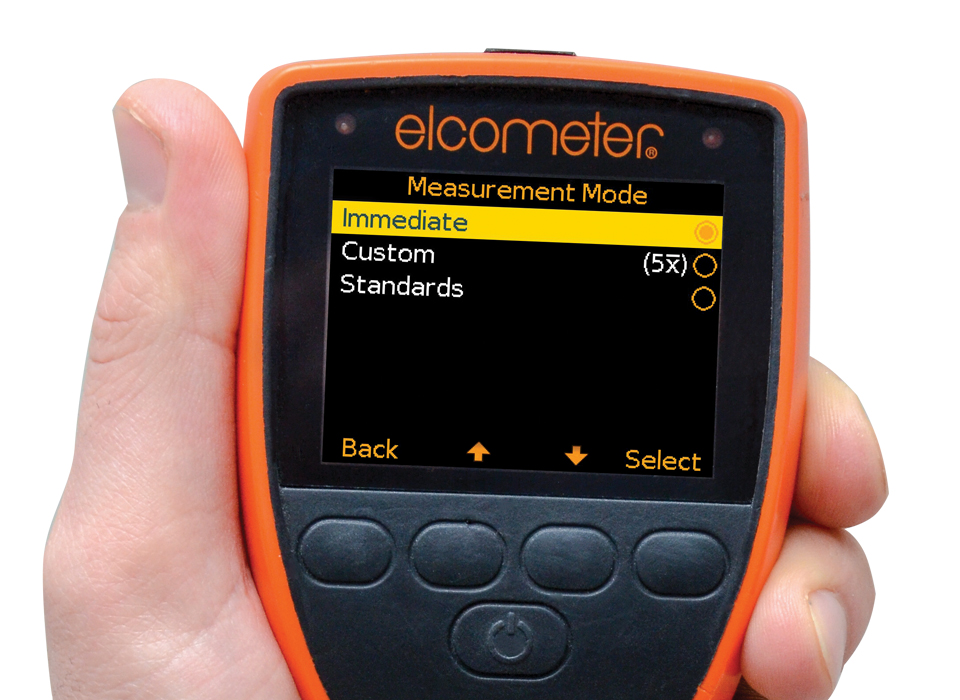

3 Measurement Modes

Whichever test method or Standard you are working to the Elcometer 224 Digital Surface Profile Gauge has a range of easy to use Measurement Modes.

Custom Mode

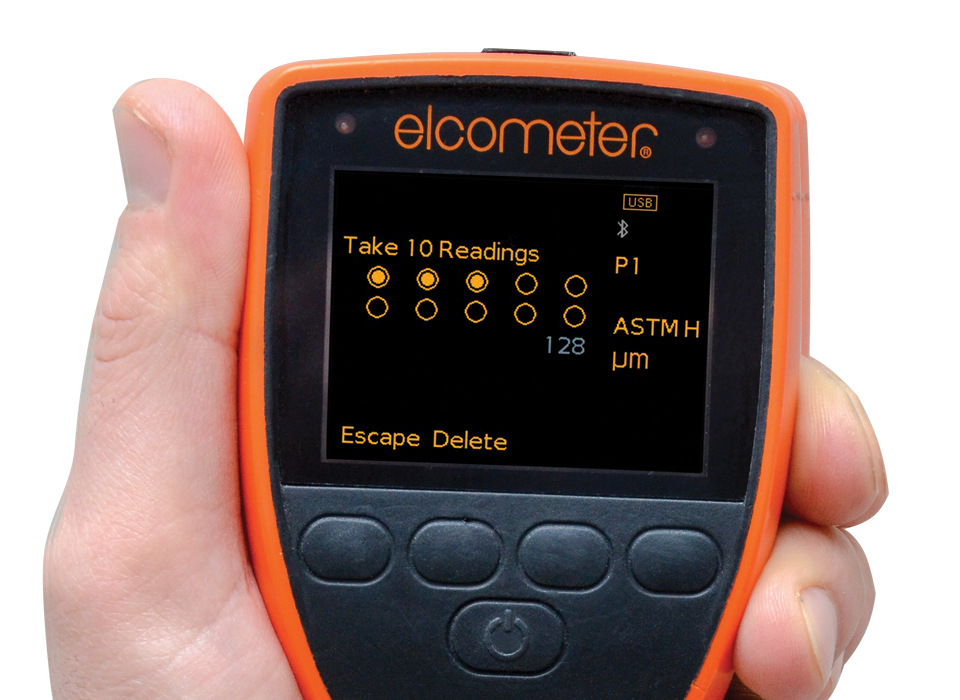

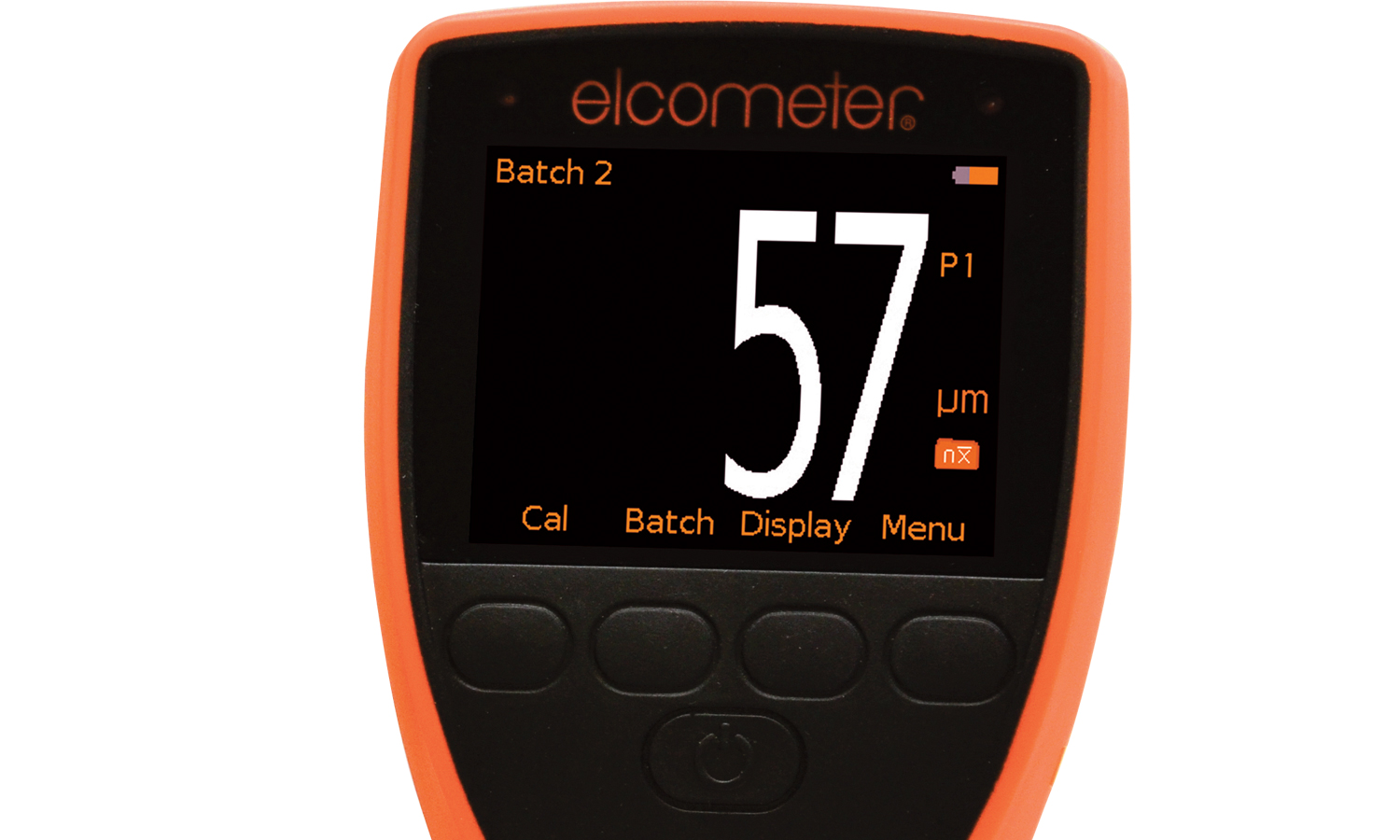

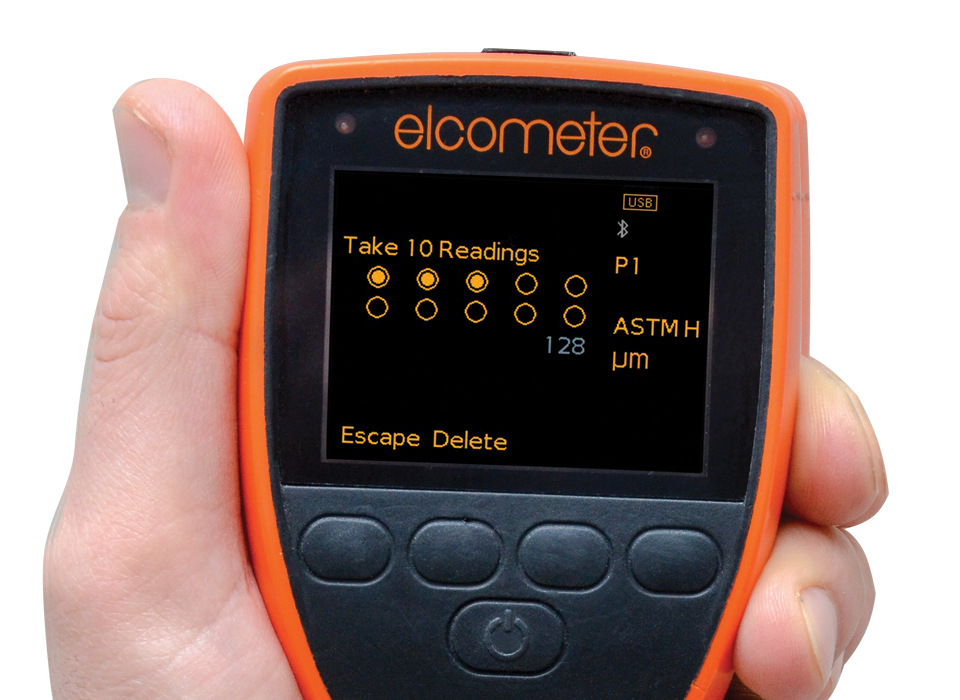

Custom ModeIn Custom mode, simply select to take either 5 or 10 profile readings per measurement then specify either the average, highest or lowest measurement of each set of readings to be displayed and saved into the batch memory4.

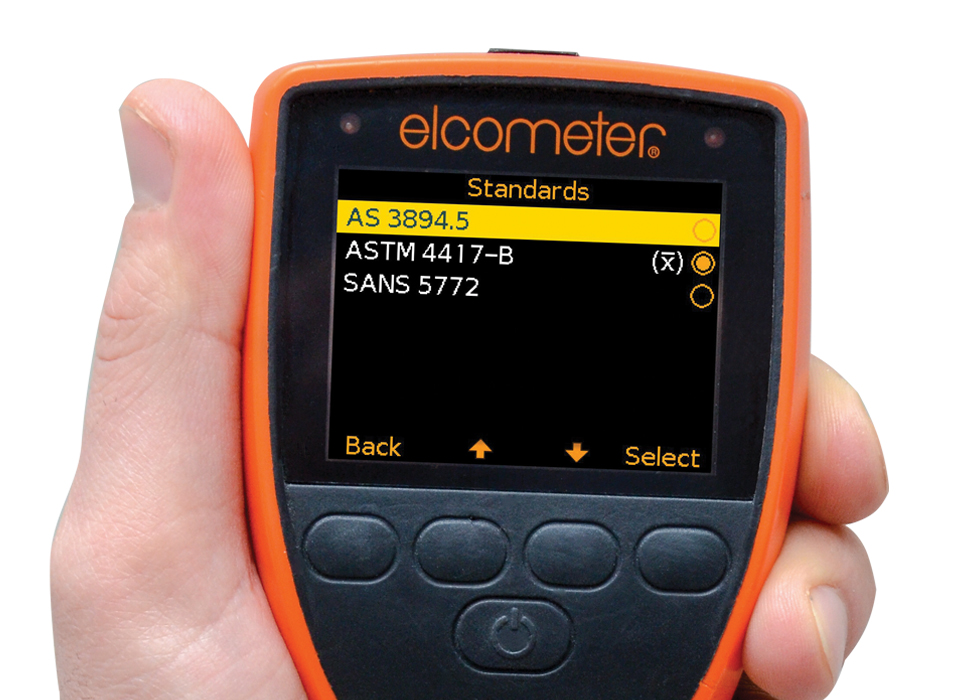

Standards Mode

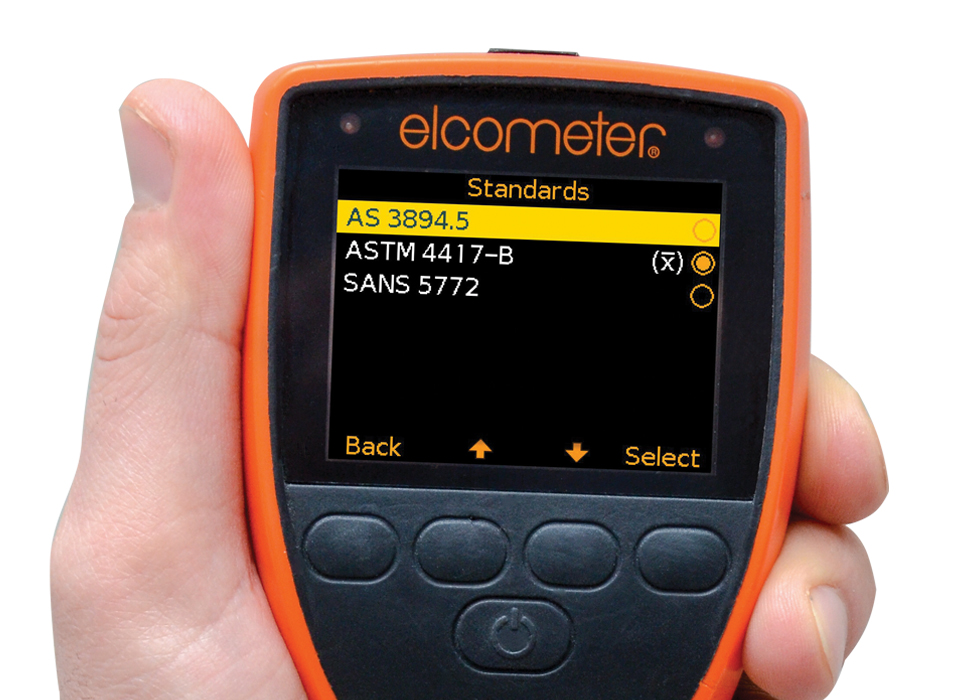

Standards ModeSelect the International Standard you are working to and the Elcometer 224 Digital Surface Profile Gauge will automatically set the data collection method accordingly. When selecting ASTM D 4417, you can even choose if the gauge stores the average or highest reading as the measurement.

Immediate Mode

Immediate ModeTake individual peak-to-valley measurements and save into the batch memory4. The Elcometer 224 Surface Profile Meter automatically calculates and displays key statistics whilst you’re inspecting, and you can set limits so the gauge will alarm whenever the reading is outside a predefined acceptable range.

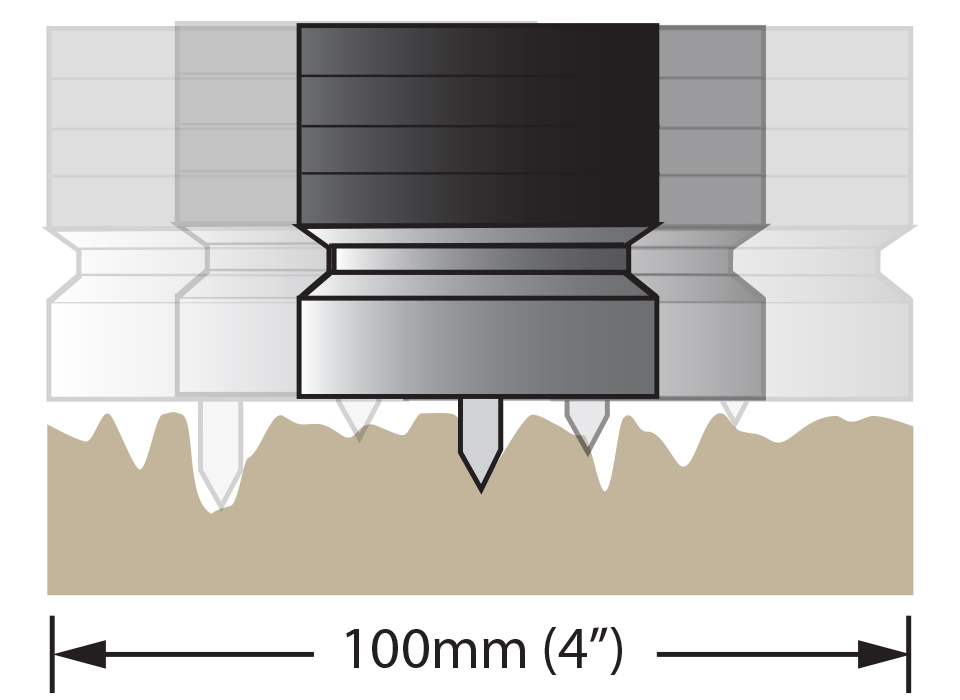

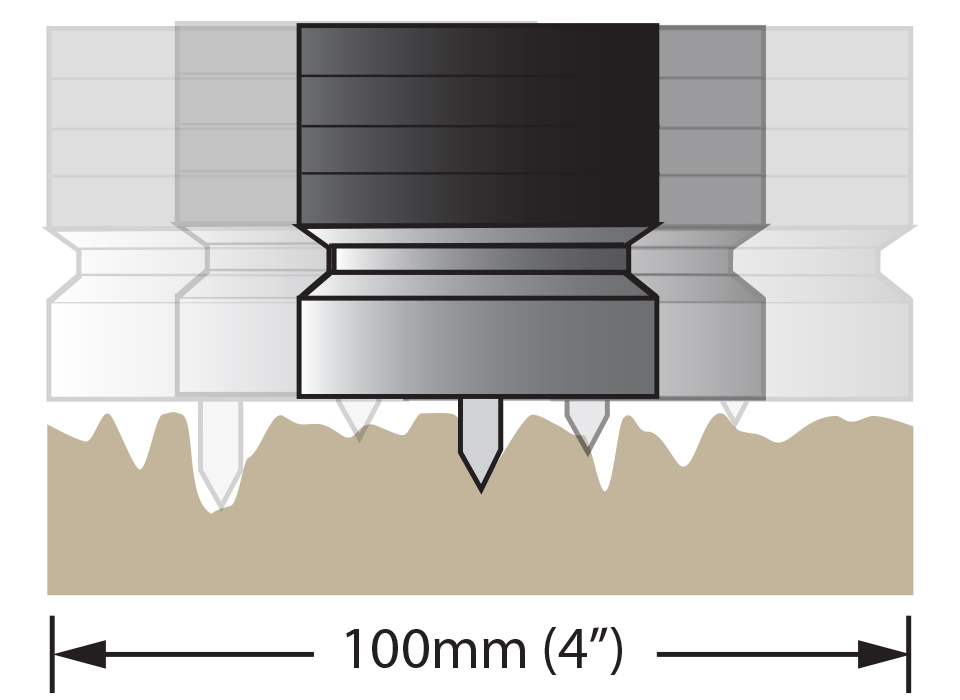

How to Measure Surface Profile

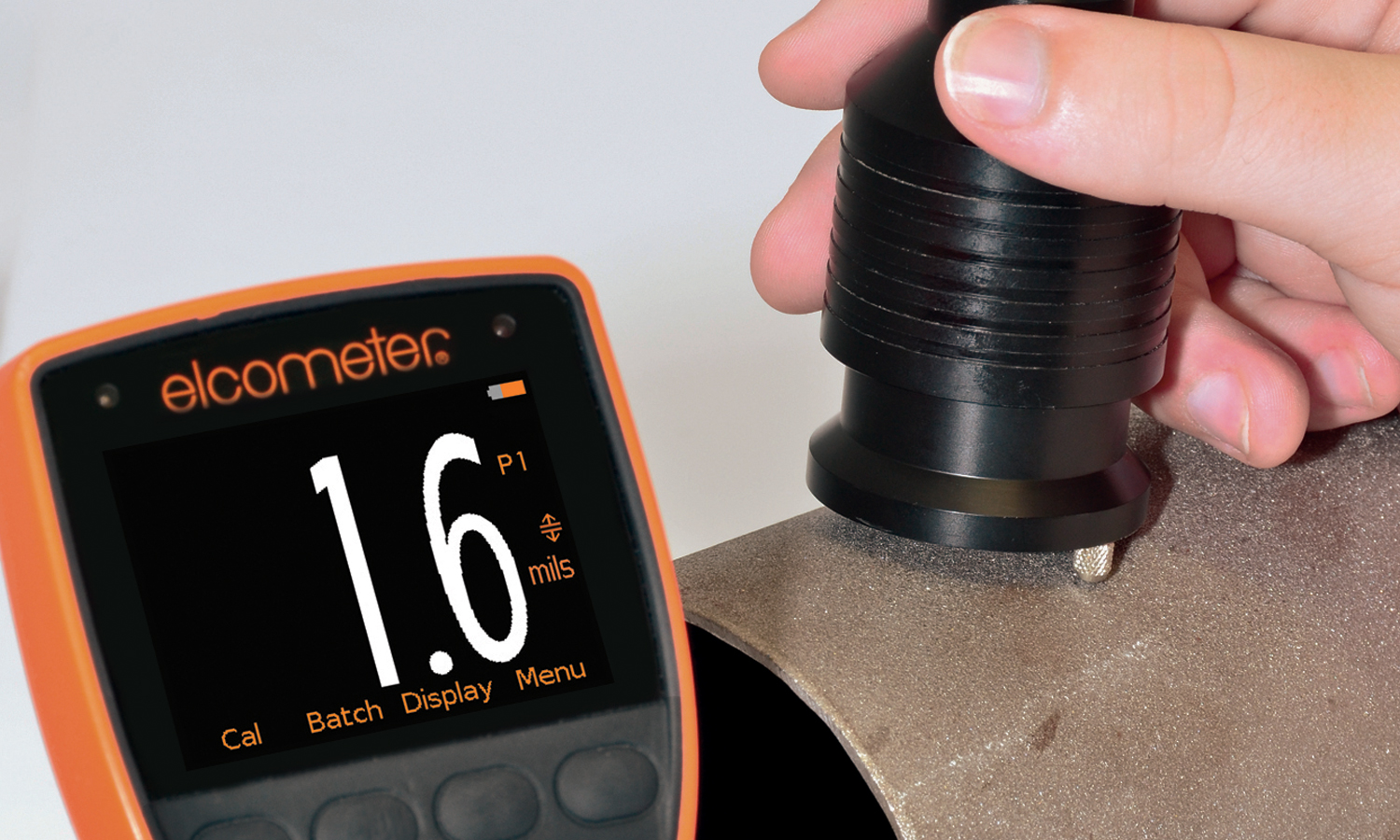

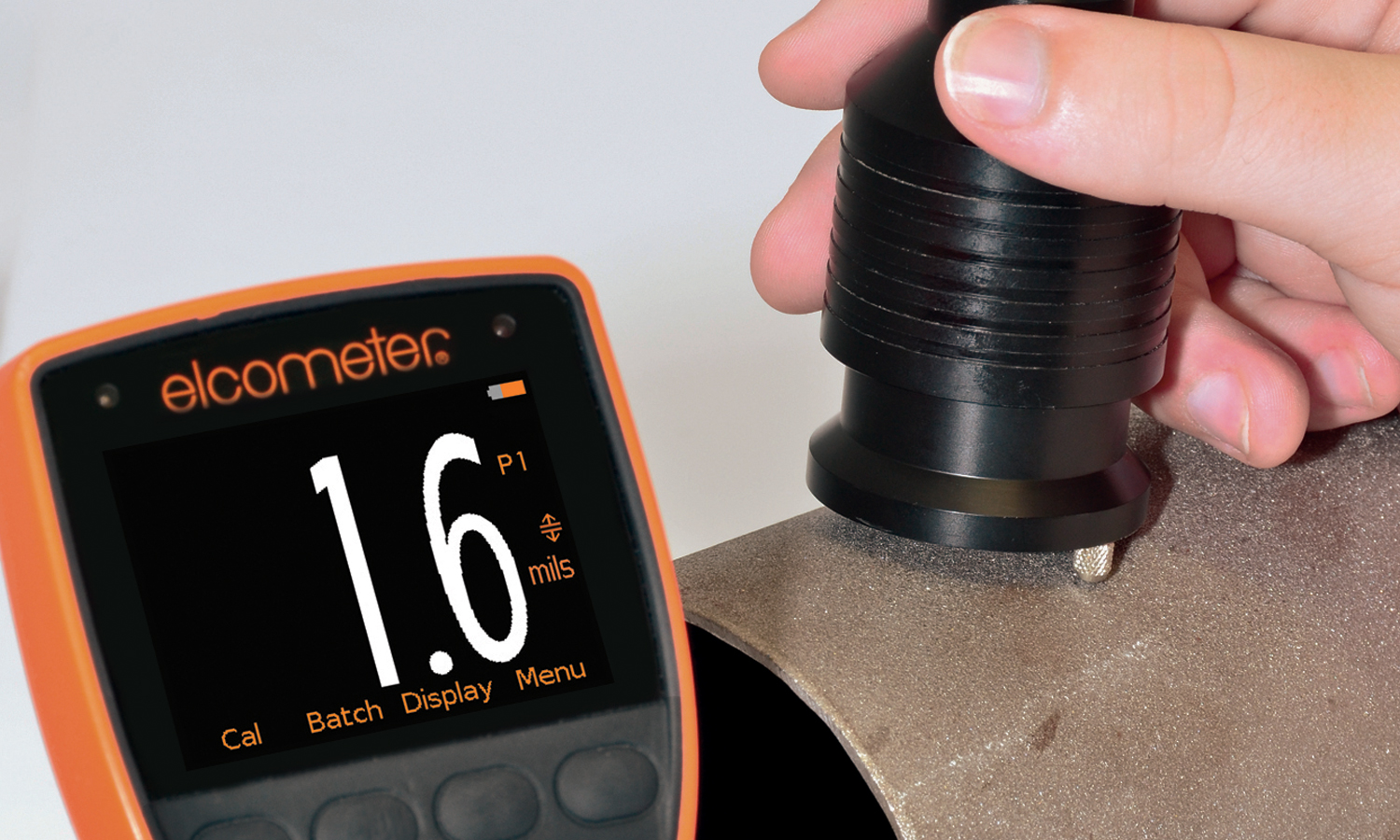

1. Ensure probe is 90° to substrate to ensure accurate readings and calibrate the gauge on a glass zero tile.

2. To take one spot measurement, take either 5 or 10 readings within a 100mm (4”) diameter area.

3. The measurement displayed is either the average peak-to-valley height or the maximum reading of the 5 or 10 readings, depending on which measurement mode you have selected.

4. To establish the average surface profile of an area, record 5 spot measurements for each 1m x 1m (3ft x 3ft) area.

Wireless Connectivity

Instantly transfer readings, statistics, and limits; via USB or Bluetooth®; to your PC or mobile device, using ElcoMaster® or your own software application, creating professional inspection reports in minutes.

Fast, accurate and very user friendly, the Elcometer 224 Surface Profile Gauge is available with or without memory and Bluetooth®.

1Compatible with iPod, iPhone and iPad.

2 Applicable Patents: GB2505193, US9261345

3The Elcometer 224 Surface Profile Gauge is supplied with a 1 year warranty against manufacturing defects. The warranty can be extended free of charge to 2 years within 60 days of purchase

4 Model T only

-

- Product Features

-

Product FeaturesElcometer 224 Digital Surface Profile Gauge

Model B Model T Fast, accurate reading rate; 50+ readings per minute1 Repeatable & reproducible measurements Easy to use menu structure; in 30+ languages Tough, impact, waterproof & dust resistant; equivalent to IP64 Bright colour screen; with permanent backlight Scratch and solvent resistant display; 2.4" (6cm) TFT Large positive feedback buttons Flat & convex surfaces2 USB power supply; via PC Test certificate 2 year gauge warranty3 Automatic rotating display; 0°, 90°, 180° & 270° Ambient light sensor; with adjustable auto brightness Emergency Light Mode Gauge software updates4; via ElcoMaster® software Data Output USB; to computer Bluetooth®: to computer, Android™ & iOS5 devices On screen statistics Number of readings, η; Mean (average), x ; Standard deviation, σ; Highest reading, Hi; Lowest reading, Lo; Coefficient of variation, CV% High & low limits; definable audible & visual alarms Number above high limit; Number below low limit; ElcoMaster® software & USB cable Date and time stamp for each reading Replaceable screen protectors Protective case Plastic transit case On screen calibration instructions; in 30+ languages Measurement Range 0-500μm (0-20mils)0-500μm (0-20mils)Number of batches 2,500Gauge memory; number of readings Last 5150,000Delete last reading 6 Limits; user definable audible & visual pass/fail warnings Gauge (g) or gauge & batch specific (gb) limits gbBatch types; normal, counted average Review, clear & delete batches Copy batches and calibration settings Alpha-numeric batch names; user definable on the gauge Fixed Batch Size Mode; with batch linking Trend graph; last 20 readings Review batch graph 1 Up to 25 readings per minute for the convex probe

2 Applicable Patents: GB2505193, US9261345

3 The Elcometer 224 is supplied with a 1 year warranty against manufacturing defects. The warranty can be extended free of charge to 2 years within 60 days of purchase via www.elcometer.com. Elcometer 224 probes are covered by a 1 year warranty.

4 Internet connection required

5 Visit www.elcometer.com/sdk to find out how to integrate Elcometer’s MFi certified products to your App.

6 Up to the last 5 readings can be deleted (Model B)

-

- Technical Information

-

Technical SpecificationElcometer 224 Digital Surface Profile Gauge

Part Number Description Certificate Integral Gauge Separate Gauge1 E224C-BI E224C-BS Elcometer 224 Model B Integral Digital Surface Profile Gauge

E224C-TI E224C-TS Elcometer 224 Model T Integral Digital Surface Profile Gauge

Display Information 2.4” (6cm) QVGA colour TFT display, 320 x 240 pixels Battery Type 2 x AA batteries, rechargeable batteries can also be used Battery Life Approximately 24 hours of continuous use at 1 reading per second2 Minimum Headroom Integral: 185mm (7.3”)

Separate: See probe technical specificationDimensions Integral: 168 x 73 x 37mm (5.61 x 2.87 x 1.46”)

Separate: 141 x 73 x 37mm (5.55 x 2.87 x 1.46”)Weight Integral Gauge (including batteries): 218g (7.69oz)

Separate Gauge (including batteries): 161g (5.68oz)Measurement Range 0-500μm (0-20mils) Probe Tip Tungsten carbide tip 60° angle Tip Radius 50μm (2mil) Operating Temperature -10 to 50°C (14 to 122°F) Storage Temperature -10 to 60°C (14 to 140°F) Accuracy3 ±5% or ±5μm (±0.2mil) Resolution 1μm (0.1mil); Packing List Elcometer 224 Digital Surface Profile Gauge, glass zero tile4, 2 x calibration foils4, wrist harness, plastic transit case (T), protective case, screen protector, probe protection cap4, 2 x AA batteries, test certificate, operating instructions, USB cable (T) & ElcoMaster® software (T) Integral Gauge Separate Gauge1 Description E224C-BI E224C-BS Elcometer 224 Model B Integral Digital Surface Profile Gauge Certificate

E224C-TI E224C-TS Elcometer 224 Model T Integral Digital Surface Profile Gauge Certificate

Display Information 2.4” (6cm) QVGA colour TFT display, 320 x 240 pixels Battery Type 2 x AA batteries, rechargeable batteries can also be used Battery Life Approximately 24 hours of continuous use at 1 reading per second2 Minimum Headroom Integral: 185mm (7.3”)

Separate: See probe technical specificationDimensions Integral: 168 x 73 x 37mm (5.61 x 2.87 x 1.46”)

Separate: 141 x 73 x 37mm (5.55 x 2.87 x 1.46”)Weight Integral Gauge (including batteries): 218g (7.69oz)

Separate Gauge (including batteries): 161g (5.68oz)Measurement Range 0-500μm (0-20mils) Probe Tip Tungsten carbide tip 60° angle Tip Radius 50μm (2mil) Operating Temperature -10 to 50°C (14 to 122°F) Storage Temperature -10 to 60°C (14 to 140°F) Accuracy3 ±5% or ±5μm (±0.2mil) Resolution 1μm (0.1mil); Packing List Elcometer 224 Digital Surface Profile Gauge, glass zero tile4, 2 x calibration foils4, wrist harness, plastic transit case (T), protective case, screen protector, probe protection cap4, 2 x AA batteries, test certificate, operating instructions, USB cable (T) & ElcoMaster® software (T) 1Probes are supplied separately

2Using default settings & lithium batteries, alkaline or rechargeable batteries may differ

3 Whichever is the greater

4 For separate gauges, the test foils, glass zero tile and probe protection cap are supplied with the separate probe.

-

- Standards

-

StandardsElcometer 224 Digital Surface Profile Gauge

ASTM D 4417-B, SANS 5772, SSPC PA 17, US Navy NSI 009-32, US Navy PPI 63101-000

-

- Downloads

-

Downloads

-

Elcometer 224 Digital Surface Profile Gauge Multi-Lingual Instruction Manual

-

Elcometer 224 Convex Surface Profile Probe Multi-Lingual Instruction Manual

-

Elcometer 224 Digital Surface Profile Gauge Datasheet

-

Elcometer 224 Model B Digital Surface Profile Gauge UKCA Declaration of Conformity

-

Elcometer 224 Model B Digital Surface Profile Gauge CE Declaration of Conformity

-

Elcometer 224 Model T Digital Surface Profile Gauge UKCA Declaration of Conformity

-

Elcometer 224 Model T Digital Surface Profile Gauge CE Declaration of Conformity

- Part Numbers

-

Part NumbersElcometer 224 Digital Surface Profile GaugeNo data found!!

-

Elcometer 224 Model B Integral Digital Surface Profile Gauge

Elcometer 224 Model B Integral Digital Surface Profile Gauge- Model: Model B

- Probe Tip: Tungsten carbide tip 60° angle

- Gauge Option: Integral

- Part Number : E224C-BI

-

Elcometer 224 Model B Integral Digital Surface Profile Gauge

Elcometer 224 Model B Integral Digital Surface Profile Gauge- Model: Model B

- Probe Tip: Tungsten carbide tip 60° angle

- Gauge Option: Integral

- Part Number : E224C-BIC

-

Elcometer 224 Model T Integral Digital Surface Profile Gauge

Elcometer 224 Model T Integral Digital Surface Profile Gauge- Model: Model T

- Probe Tip: Tungsten carbide tip 60° angle

- Gauge Option: Integral

- Part Number : E224C-TI

-

Elcometer 224 Model T Integral Digital Surface Profile Gauge

Elcometer 224 Model T Integral Digital Surface Profile Gauge- Model: Model T

- Probe Tip: Tungsten carbide tip 60° angle

- Gauge Option: Integral

- Part Number : E224C-TIC

-

Elcometer 224 Model B Separate Digital Surface Profile Gauge

Elcometer 224 Model B Separate Digital Surface Profile Gauge- Model: Model B

- Probe Tip: Tungsten carbide tip 60° angle

- Gauge Option: Separate

- Part Number : E224C-BS

-

Elcometer 224 Model B Separate Digital Surface Profile Gauge

Elcometer 224 Model B Separate Digital Surface Profile Gauge- Model: Model B

- Probe Tip: Tungsten carbide tip 60° angle

- Gauge Option: Separate

- Part Number : E224C-BSC

-

Elcometer 224 Model T Separate Digital Surface Profile Gauge

Elcometer 224 Model T Separate Digital Surface Profile Gauge- Model: Model T

- Probe Tip: Tungsten carbide tip 60° angle

- Gauge Option: Separate

- Part Number : E224C-TS

-

Elcometer 224 Model T Separate Digital Surface Profile Gauge

Elcometer 224 Model T Separate Digital Surface Profile Gauge- Model: Model T

- Probe Tip: Tungsten carbide tip 60° angle

- Gauge Option: Separate

- Part Number : E224C-TSC

- Accessories

-

AccessoriesElcometer 224 Digital Surface Profile Gauge

Part Number: T99921325

Part Number: T99921325 Part Number: T22419793

Part Number: T22419793 Part Number: T22420072

Part Number: T22420072 Part Number: T22421882C

Part Number: T22421882C Part Number: T99924797

Part Number: T99924797 Part Number: T99922341

Part Number: T99922341 Part Number: T22420053

Part Number: T22420053 Part Number: T22420095

Part Number: T22420095 Part Number: T45622371

Part Number: T45622371 Part Number: T224C500US

Part Number: T224C500US Part Number: T224C500UARM

Part Number: T224C500UARM Part Number: T224C500UX

Part Number: T224C500UX Part Number: T224C500UXARM

Part Number: T224C500UXARM

Welcome to Elcometer.tv

Your ultimate training channel

- Home

- Coatings Inspection

- Coatings Inspection Division

- Surface Profile

- Elcometer 224 Digital Surface Profile Gauge

Elcometer 224 Digital Surface Profile Gauge

- Protective Coatings

The Elcometer 224 Digital Surface Profile Gauge provides the very latest in surface profile measuring technology for measuring surface profile on either flat or curved surfaces.

Accurate Surface Profile Measurements

- Can be used in accordance with National and International Standards

- Temperature stable measurements

- Statistics are calculated and displayed in real time during inspection

- Live and batch readings graph format for instant analysis

- Measurement capability to ±5%

A Powerful Surface Profile Gauge

- User replaceable tough tungsten carbide tip, can be used for up to 20,000 surface profile readings

- USB and Bluetooth® data output to iPhone¹ or Android™ devices

- Measures surface profiles up to 500μm (20mils)

- Review batch data or last 20 readings in a graph format

- Integral & separate probe options for flat and convex² curved surface

Efficient Inspections

- Fast reading rate of 50+ per minute

- Integral and separate probe versions to suit your application

- Alpha numeric batch identification

- Compatible with ElcoMaster® software and ElcoMaster® Mobile App

- Powersave Mode with tap awake

Summary

Elcometer 224 Digital Surface Profile Gauge

-

Fast and reliable peak-to-valley surface profile measurement

-

Accurately measure surface profile on flat or curved surfaces up to 500μm (20mils)

-

Measures both average peak-to-valley and average maximum peak-to-valley height

-

Portable, rugged hand-held design is ideal for field use

The Elcometer 224 surface profile meter is available in two different models: Model B and Model T. Each surface profile meter provides the user with increasing functionality - from the entry level Elcometer 224 Model B Surface Profile Gauge, to the top of the range Elcometer 224 Model T Surface Profile Gauge, with memory, alpha-numeric batching and Bluetooth® communication.

Standard and armoured probes are available for the separate models, providing even greater measurement flexibility. Elcometer surface profile probes are supplied with a glass zero plate, calibration test foils (nominal values 125µm (5.0mils) & 500µm (20mils)) and an Elcometer Test Certificate.ElcoMaster® Data Management Software

Inspectors can spend up to 30% of their working week producing reports. ElcoMaster® Software saves time and money by producing professional bespoke reports - even when out on site.

Downloads-

Elcometer 224 Digital Surface Profile Gauge Multi-Lingual Instruction Manual

-

Elcometer 224 Convex Surface Profile Probe Multi-Lingual Instruction Manual

-

Elcometer 224 Digital Surface Profile Gauge Datasheet

-

Elcometer 224 Model B Digital Surface Profile Gauge UKCA Declaration of Conformity

-

Elcometer 224 Model B Digital Surface Profile Gauge CE Declaration of Conformity

-

Elcometer 224 Model T Digital Surface Profile Gauge UKCA Declaration of Conformity

-

Elcometer 224 Model T Digital Surface Profile Gauge CE Declaration of Conformity

Key Features

Elcometer 224 Digital Surface Profile Gauge

User Friendly Gauge

- Large buttons ideal for gloved hands

- Easy to use menus in multiple languages

- High contrast colour LCD with auto rotate

- High and low reading limit indicators

- Factory calibrated for immediate use

Durability in Tough Environments

- Sealed, heavy duty and impact resistant

- Dust and waterproof equivalent to IP64

- Suitable for use in harsh environments

- Scratch and solvent resistant display

- Durable gauge and probe construction

A Reliable Surface Profile Gauge

- Repeatable and reproducible profile measurements

- 2 year gauge warranty³

- Supplied with fully traceable Test Certificates

- Batch & individual readings are date and time stamped

3 Measurement Modes

Whichever test method or Standard you are working to the Elcometer 224 Digital Surface Profile Gauge has a range of easy to use Measurement Modes.

Custom Mode

Custom ModeIn Custom mode, simply select to take either 5 or 10 profile readings per measurement then specify either the average, highest or lowest measurement of each set of readings to be displayed and saved into the batch memory4.

Standards Mode

Standards ModeSelect the International Standard you are working to and the Elcometer 224 Digital Surface Profile Gauge will automatically set the data collection method accordingly. When selecting ASTM D 4417, you can even choose if the gauge stores the average or highest reading as the measurement.

Immediate Mode

Immediate ModeTake individual peak-to-valley measurements and save into the batch memory4. The Elcometer 224 Surface Profile Meter automatically calculates and displays key statistics whilst you’re inspecting, and you can set limits so the gauge will alarm whenever the reading is outside a predefined acceptable range.

How to Measure Surface Profile

1. Ensure probe is 90° to substrate to ensure accurate readings and calibrate the gauge on a glass zero tile.

2. To take one spot measurement, take either 5 or 10 readings within a 100mm (4”) diameter area.

3. The measurement displayed is either the average peak-to-valley height or the maximum reading of the 5 or 10 readings, depending on which measurement mode you have selected.

4. To establish the average surface profile of an area, record 5 spot measurements for each 1m x 1m (3ft x 3ft) area.

Wireless Connectivity

Instantly transfer readings, statistics, and limits; via USB or Bluetooth®; to your PC or mobile device, using ElcoMaster® or your own software application, creating professional inspection reports in minutes.

Fast, accurate and very user friendly, the Elcometer 224 Surface Profile Gauge is available with or without memory and Bluetooth®.

1Compatible with iPod, iPhone and iPad.

2 Applicable Patents: GB2505193, US9261345

3The Elcometer 224 Surface Profile Gauge is supplied with a 1 year warranty against manufacturing defects. The warranty can be extended free of charge to 2 years within 60 days of purchase

4 Model T only

Product FeaturesElcometer 224 Digital Surface Profile GaugeModel B Model T Fast, accurate reading rate; 50+ readings per minute1 Repeatable & reproducible measurements Easy to use menu structure; in 30+ languages Tough, impact, waterproof & dust resistant; equivalent to IP64 Bright colour screen; with permanent backlight Scratch and solvent resistant display; 2.4" (6cm) TFT Large positive feedback buttons Flat & convex surfaces2 USB power supply; via PC Test certificate 2 year gauge warranty3 Automatic rotating display; 0°, 90°, 180° & 270° Ambient light sensor; with adjustable auto brightness Emergency Light Mode Gauge software updates4; via ElcoMaster® software Data Output USB; to computer Bluetooth®: to computer, Android™ & iOS5 devices On screen statistics Number of readings, η; Mean (average), x ; Standard deviation, σ; Highest reading, Hi; Lowest reading, Lo; Coefficient of variation, CV% High & low limits; definable audible & visual alarms Number above high limit; Number below low limit; ElcoMaster® software & USB cable Date and time stamp for each reading Replaceable screen protectors Protective case Plastic transit case On screen calibration instructions; in 30+ languages Measurement Range 0-500μm (0-20mils)0-500μm (0-20mils)Number of batches 2,500Gauge memory; number of readings Last 5150,000Delete last reading 6 Limits; user definable audible & visual pass/fail warnings Gauge (g) or gauge & batch specific (gb) limits gbBatch types; normal, counted average Review, clear & delete batches Copy batches and calibration settings Alpha-numeric batch names; user definable on the gauge Fixed Batch Size Mode; with batch linking Trend graph; last 20 readings Review batch graph 1 Up to 25 readings per minute for the convex probe

2 Applicable Patents: GB2505193, US9261345

3 The Elcometer 224 is supplied with a 1 year warranty against manufacturing defects. The warranty can be extended free of charge to 2 years within 60 days of purchase via www.elcometer.com. Elcometer 224 probes are covered by a 1 year warranty.

4 Internet connection required

5 Visit www.elcometer.com/sdk to find out how to integrate Elcometer’s MFi certified products to your App.

6 Up to the last 5 readings can be deleted (Model B)

Technical SpecificationElcometer 224 Digital Surface Profile GaugePart Number Description Certificate Integral Gauge Separate Gauge1 E224C-BI E224C-BS Elcometer 224 Model B Integral Digital Surface Profile Gauge

E224C-TI E224C-TS Elcometer 224 Model T Integral Digital Surface Profile Gauge

Display Information 2.4” (6cm) QVGA colour TFT display, 320 x 240 pixels Battery Type 2 x AA batteries, rechargeable batteries can also be used Battery Life Approximately 24 hours of continuous use at 1 reading per second2 Minimum Headroom Integral: 185mm (7.3”)

Separate: See probe technical specificationDimensions Integral: 168 x 73 x 37mm (5.61 x 2.87 x 1.46”)

Separate: 141 x 73 x 37mm (5.55 x 2.87 x 1.46”)Weight Integral Gauge (including batteries): 218g (7.69oz)

Separate Gauge (including batteries): 161g (5.68oz)Measurement Range 0-500μm (0-20mils) Probe Tip Tungsten carbide tip 60° angle Tip Radius 50μm (2mil) Operating Temperature -10 to 50°C (14 to 122°F) Storage Temperature -10 to 60°C (14 to 140°F) Accuracy3 ±5% or ±5μm (±0.2mil) Resolution 1μm (0.1mil); Packing List Elcometer 224 Digital Surface Profile Gauge, glass zero tile4, 2 x calibration foils4, wrist harness, plastic transit case (T), protective case, screen protector, probe protection cap4, 2 x AA batteries, test certificate, operating instructions, USB cable (T) & ElcoMaster® software (T) Integral Gauge Separate Gauge1 Description E224C-BI E224C-BS Elcometer 224 Model B Integral Digital Surface Profile Gauge Certificate

E224C-TI E224C-TS Elcometer 224 Model T Integral Digital Surface Profile Gauge Certificate

Display Information 2.4” (6cm) QVGA colour TFT display, 320 x 240 pixels Battery Type 2 x AA batteries, rechargeable batteries can also be used Battery Life Approximately 24 hours of continuous use at 1 reading per second2 Minimum Headroom Integral: 185mm (7.3”)

Separate: See probe technical specificationDimensions Integral: 168 x 73 x 37mm (5.61 x 2.87 x 1.46”)

Separate: 141 x 73 x 37mm (5.55 x 2.87 x 1.46”)Weight Integral Gauge (including batteries): 218g (7.69oz)

Separate Gauge (including batteries): 161g (5.68oz)Measurement Range 0-500μm (0-20mils) Probe Tip Tungsten carbide tip 60° angle Tip Radius 50μm (2mil) Operating Temperature -10 to 50°C (14 to 122°F) Storage Temperature -10 to 60°C (14 to 140°F) Accuracy3 ±5% or ±5μm (±0.2mil) Resolution 1μm (0.1mil); Packing List Elcometer 224 Digital Surface Profile Gauge, glass zero tile4, 2 x calibration foils4, wrist harness, plastic transit case (T), protective case, screen protector, probe protection cap4, 2 x AA batteries, test certificate, operating instructions, USB cable (T) & ElcoMaster® software (T) 1Probes are supplied separately

2Using default settings & lithium batteries, alkaline or rechargeable batteries may differ

3 Whichever is the greater

4 For separate gauges, the test foils, glass zero tile and probe protection cap are supplied with the separate probe.StandardsElcometer 224 Digital Surface Profile GaugeASTM D 4417-B, SANS 5772, SSPC PA 17, US Navy NSI 009-32, US Navy PPI 63101-000

Part NumbersElcometer 224 Digital Surface Profile GaugeNo data found!!-

Elcometer 224 Model B Integral Digital Surface Profile Gauge

Elcometer 224 Model B Integral Digital Surface Profile Gauge- Model: Model B

- Probe Tip: Tungsten carbide tip 60° angle

- Gauge Option: Integral

- Part Number : E224C-BI

-

Elcometer 224 Model B Integral Digital Surface Profile Gauge

Elcometer 224 Model B Integral Digital Surface Profile Gauge- Model: Model B

- Probe Tip: Tungsten carbide tip 60° angle

- Gauge Option: Integral

- Part Number : E224C-BIC

-

Elcometer 224 Model T Integral Digital Surface Profile Gauge

Elcometer 224 Model T Integral Digital Surface Profile Gauge- Model: Model T

- Probe Tip: Tungsten carbide tip 60° angle

- Gauge Option: Integral

- Part Number : E224C-TI

-

Elcometer 224 Model T Integral Digital Surface Profile Gauge

Elcometer 224 Model T Integral Digital Surface Profile Gauge- Model: Model T

- Probe Tip: Tungsten carbide tip 60° angle

- Gauge Option: Integral

- Part Number : E224C-TIC

-

Elcometer 224 Model B Separate Digital Surface Profile Gauge

Elcometer 224 Model B Separate Digital Surface Profile Gauge- Model: Model B

- Probe Tip: Tungsten carbide tip 60° angle

- Gauge Option: Separate

- Part Number : E224C-BS

-

Elcometer 224 Model B Separate Digital Surface Profile Gauge

Elcometer 224 Model B Separate Digital Surface Profile Gauge- Model: Model B

- Probe Tip: Tungsten carbide tip 60° angle

- Gauge Option: Separate

- Part Number : E224C-BSC

-

Elcometer 224 Model T Separate Digital Surface Profile Gauge

Elcometer 224 Model T Separate Digital Surface Profile Gauge- Model: Model T

- Probe Tip: Tungsten carbide tip 60° angle

- Gauge Option: Separate

- Part Number : E224C-TS

-

Elcometer 224 Model T Separate Digital Surface Profile Gauge

Elcometer 224 Model T Separate Digital Surface Profile Gauge- Model: Model T

- Probe Tip: Tungsten carbide tip 60° angle

- Gauge Option: Separate

- Part Number : E224C-TSC

Welcome to Elcometer.tv

Your ultimate training channelAccessoriesElcometer 224 Digital Surface Profile Gauge Part Number: T99921325

Part Number: T99921325 Part Number: T22419793

Part Number: T22419793 Part Number: T22420072

Part Number: T22420072 Part Number: T22421882C

Part Number: T22421882C Part Number: T99924797

Part Number: T99924797 Part Number: T99922341

Part Number: T99922341 Part Number: T22420053

Part Number: T22420053 Part Number: T22420095

Part Number: T22420095 Part Number: T45622371

Part Number: T45622371 Part Number: T224C500US

Part Number: T224C500US Part Number: T224C500UARM

Part Number: T224C500UARM Part Number: T224C500UX

Part Number: T224C500UX Part Number: T224C500UXARM

Part Number: T224C500UXARM

-

-