Elcometer AGV Automatic General Valve

The Elcometer AGV Automatic General Valve ensures precision abrasive control and fail-safe shut down of both the blast stream and media flow.

Elcometer AGV Automatic General Valve

The Elcometer AGV Automatic General Valve ensures precision abrasive control and fail-safe shut down of both the blast stream and media flow.

Summary

Elcometer AGV Automatic General Valve

The Elcometer AGV Automatic General Valve utilises all the benefits of our General Valve, including precision control of abrasive media, but features an advanced pneumatic control system which enables automatic media shut off from the blast nozzle.

The ability to immediately halt abrasive flow serves to reduce material wastage whilst minimising downtime by preventing blockages within the Blast Machine.

Tested to a maximum working pressure of 15bar (217psi), the valve's built-in fail-safe feature provides operators with peace of mind. What's more, its universal design ensures that it can be fitted onto most Blast Machines available on the market.

Visit our key features section below for more information on its how unique design enables improved abrasive blasting results.

Key Features

Elcometer AGV Automatic General Valve

Versatile

Ideal for metering fine, heavy or aggressive abrasive materials, such as shot, grit and aluminium oxide, the pinch valve style design prevents the valve body from coming into contact with the abrasive stream as it is protected by the hardwearing elcoTOUGH™ Rubber Liner which lasts up to three times longer than market alternatives.

Easy to Use

With a built-in media flow indicator, the Elcometer Automatic General Valve allows the operator to adjust the media flow even whilst blasting, ensuring precise abrasive metering for a smooth, regulated flow.

Fast to Service

The liner wear indicator provides feedback on when our long-lasting liners will need replacing. When the time comes, replacement can be done quickly, without training, as it does not have to be removed from the Blast Machine.

More Than a Standard Grit Valve: How the Elcometer AGV Works

As the Elcometer AGV Automatic General Valve works pneumatically, it is necessary to provide air to the valve and control it via the deadman's handle. Air is supplied via the yellow return hose of the deadman's handle which is connected to the frame of the Blast Machine.

The connector has a 'T' piece attached which allows returned air to enter the remote control valve and Automatic General Valve.

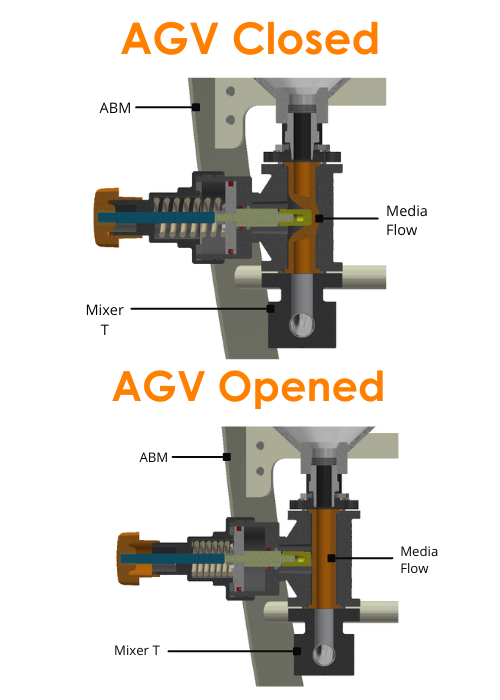

This means that when the deadman's handle is closed and blasting is ongoing, air will be fed into the AGV. When the blaster releases the handle, air escapes and is no longer fed to the valve.

When blasting is not in operation, the AGV will adopt a naturally closed position which ensures that grit doesn't feed into the mixer 'T'. This is achieved using a spring to ensure that a 'chisel' tool squeezes the abrasive liner shut.

Closing the deadman's handle allows air back into the valve which pushes against the spring to a predtermined position as set by the orange control indicator. Subsequently, grit begins to flow into the mixer 'T' at the rate required for the job in hand.

-

Elcometer AGV Automatic General Valve

Elcometer AGV Automatic General Valve- PED Part Number: AGV-B

- ASME Part Number: AGV-N

PED Part Number: MT28553ASME Part Number: MT28553N

PED Part Number: MT28553ASME Part Number: MT28553N PED Part Number: MT28552ASME Part Number: MT28552N

PED Part Number: MT28552ASME Part Number: MT28552N Part Number: GV-LINER1

Part Number: GV-LINER1 Part Number: GV-LINER5

Part Number: GV-LINER5 Part Number: GV-LINER20

Part Number: GV-LINER20