Abrasive Control - Precision at your Fingertips

The Elcometer Automatic General Valve (AGV) has all the advantages of the Elcometer GV - with features such as fine-tuning and long-life abrasive liners, but unlike a standard grit valve or the Elcometer GV, the Elcometer AGV uses a pneumatic control system that opens and closes the abrasive flow valve as soon as the deadman’s handle is pressed or released.

When the deadman's handle is released, the valve in the AGV is automatically closed, cutting off the flow of abrasive from the abrasive blast machine into the mixer 'T'. Stopping the flow of abrasive when the blast machine has been depressurised (following the release of the deadman's handle), helps to:

- save abrasive

- reduce wear in the mixer 'T'

- maximise the lifetime, minimise downtime

- reduce blockages from excessive blast material

- minimise the risk of choking the blast machine

So, how does it work?

As the AGV works pneumatically, it is necessary to provide air to the valve and control it via the deadman’s handle. The air is conveniently drawn off the yellow return hose of the deadman’s handle, connected to the ABM frame. The connector has a ‘T’ piece attached to allow the returned air from the deadman’s handle to go into the Remote-Control Valve and also into the AGV. Note that the hose connecting from the frame to the AGV is red in colour and not coloured blue since the air has not been filtered.

This essentially means that when the deadman’s handle is closed and the blaster is blasting then air is fed into the AGV. When the blaster releases the deadman’s handle then air escapes from the hole in the deadman’s handle and is no longer fed into the AGV. The AGV is termed ‘normally closed’ so that grit doesn’t feed into the mixer ‘T’ when it is not energised. The normally closed condition is achieved using a spring to ensure that a ‘chisel’ tool squeezes the abrasive liner shut.

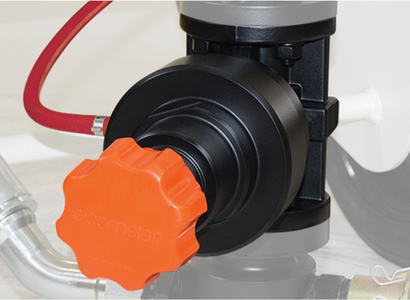

When the blaster closes the deadman’s handle air is fed into the AGV and pushed against the spring to a predetermined position as set by the orange control knob on the valve. This subsequently opens the liner to that set position and grit begins to feed into the mixer ‘T’.