How to Measure Gloss using a Gloss Meter

Gloss is an important aspect of our visual perception of objects. The perception of gloss can relate to a product’s finish, texture and how a sample is illuminated and viewed. Surfaces with high reflectance are perceived as glossy, shiny or lustrous, whilst less reflective surfaces are perceived as semi-gloss or matt.

Gloss can be measured by several different techniques. One of them is by using an optical instrument called a gloss meter. A glossmeter provides quantifiable gloss measurements, expressed as gloss units (GU).

How to Measure Gloss

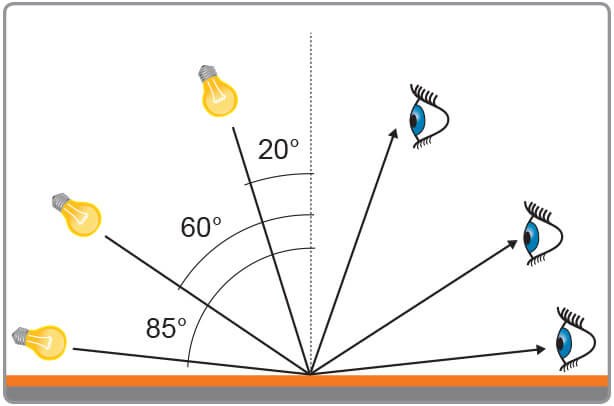

Gloss is measured by directing a constant intensity light beam, at a fixed angle, onto the test surface and then monitoring the amount of reflected light from the same angle. This specular reflectance is measured using a glossmeter. Different surfaces require different reflective angles.

High Gloss: Surfaces with a brilliant or highly polished finish reflect images clearly. This distinct reflection is caused by the incident light reflecting on the surface in a specular direction.

Semi & Matt Gloss: Semi and matt surfaces reflect images less distinctly and with reduced intensity. On semi or matt surfaces light not only reflects in a specular direction but also is scattered causing the reflected image to appear diffused.

Choosing the Correct Angle for Gloss Measurement

Gloss measurement is based on the amount of light reflected on the surface relative to a polished glass reference standard, measured in Gloss Units (GU). The amount of light that is reflected on the surface is dependent on the angle of incidence and the properties of the surface.

Gloss is categorised as either matt, semi or high gloss. In order to determine the most appropriate measurement angle start with a glossmeter set at a 60° angle of incidence.

If the result is between 10 - 70GU, the coating is termed 'semi-gloss' and should be measured using the 60° angle on the glossmeter. If the result is less than 10GU, the product is 'low gloss' and should be measured using the 85° angle on the glossmeter and if it is greater than 70GU, the product is known as 'high gloss' and should be measured using the 20° angle on the glossmeter.

All three angles should be recorded (20, 60 & 85°) when measuring gloss on anodised metals to ensure a complete understanding of the specular reflectance between the coating and the metal substrate.

| Gloss Range | 60° value | Measure with |

| High Gloss | > 70GU | 20° |

| Semi Gloss | 10 - 70GU | 60° |

| Low/ Matt | < 10GU | 85° |

% Reflectance

Whilst the Gloss Unit (GU) scale is linear, each angle of incidence has a different measurement range; 0 – 2000GU (20°), 0 – 1000GU (60°), 0 – 160GU (85°).

% Reflectance compares the amount of light energy transmitted and received by a gloss meter and expresses the value as a percentage of the angle of incident's full measurement range and the value is displayed as a percentage relative to the selected angle of incidence.

As the measurement range for a 20° gloss meter is 0 -2000GU; a value of 1000GU at 20° would be expressed as 50%20, and a value of 500GU would be expressed as 25%20. A value of 500GU at 60°, but would be expressed as 50%60 as the measurement range for the 60° is 0 – 1000GU. The shinier a surface is, the closer the value will be to 100%.

Materials with a high refractive index, such as clear plastics or varnishes, can have measurement values above 100GU. Highly reflective metals can have gloss values up to 2000GU. Furthermore, the measurement value can be increased for transparent materials due to multiple reflections in the bulk of the material. In all these cases, it is common to express the measurement results in % Reflectance.

Haze (HU)

Haze causes a drop in reflected contrast and causes 'halos' to appear around the reflected light sources, dramatically reducing the visual quality.

In accordance with ASTM D4039 Haze, within the Elcometer 480 Gloss Meter, is defined as the numeric difference between the specular reflectance at 60° and 20°.

This is expressed in Haze Units (HU).

Glossmeters (also Gloss Meters)

Elcometer offer a comprehensive range of single, dual & triple angle glossmeters and DOI meters, which provide Gloss, % Reflectance and Haze measurements on a wide range of surfaces.

The Elcometer 480 Glossmeter is available as either a simple entry-level 60° gloss meter or state-of-the-art Single, Dual or Triple Angle Glossmeter with % Reflectance and Haze measurement capability.

No two inspections are the same. It is for this reason that the Elcometer 480 is equipped with three gloss measurement modes: Standard Mode - to take an individual spot measurement, Auto Repeat Mode - which automatically takes individual gloss readings at a user-definable rate and Scan Mode - for measuring gloss on large surfaces providing the average, highest and lowest readings.

The Elcometer 480 gloss meter’s colour LCD display is fully customisable, and is scratch and solvent resistant. For more detailed gloss analysis, customise your screen to display statistics, display readings as a graph or use the differential screen for a quick pass/fail analysis.