Elcometer 266 DC (直流)电火花检漏仪

- 防护涂料

Elcometer266给高压直流测试涂层孔隙带来革命性的变化,检测比以往任何时候更加安全,方便,可靠。

- 概要

-

概要

-

界面友好

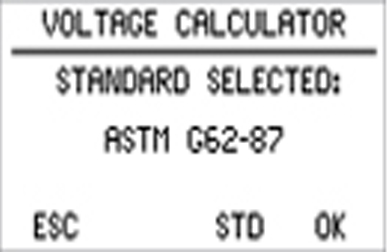

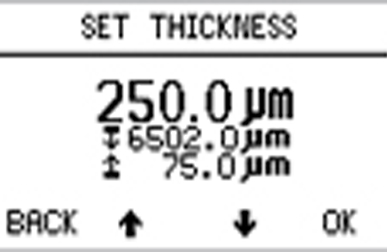

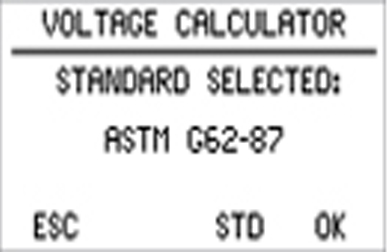

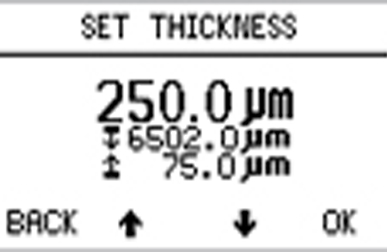

电压计算器根据涂层厚度值自动设置正确的电压。无需使用查找表。

安全

手柄上有一个双安全开关,可以避免意外接通和 专用的罗纹,提供卓越的保护。

万能

要更改最大电压范围,请选择其他手柄; 5kV,15kV或30kV DC或30kV DC连续。

易高266电火花检漏仪可以用来测试达7.5mm(300mils)厚的涂层孔隙, 是理想管道上涂层和其他保护涂层的检测.

这个检漏仪具有一个内置电压计算器, 确定和设置基于所述测试标准和被测试涂层的厚度正确的测试电压。

-

- 主要特点

-

主要特点

Elcometer 266 DC (直流)电火花检漏仪

- 电压计算器功能自动根据涂层厚度值来设定电压

- 可调电压:

- 0.5kV - 1kV:间隔50V

- 1kV - 30kV: 间隔100V

- 手柄上的双重安全开关, 以避免意外的开关(只有灰/橙探头手柄)

- 内部电压交验仪确保所选电压就是测试电压

- 可视和声音报警手柄上的LED和大声的报警,清晰提示检测到孔隙

- 要改变最大电压范围, 选择不同的手柄; 5kV, 15kV或30kVDC或30kV DC连续

- 多种探头刷和弹簧可使用

易高266 DC电火花检漏仪特点说明

电压计算器

电压计算功能自动根据涂层厚度值来设定电压。带内置式电压计算器,无需查看换算表。输入测试标准和涂层厚度,仪器会自动算出正确的电压。

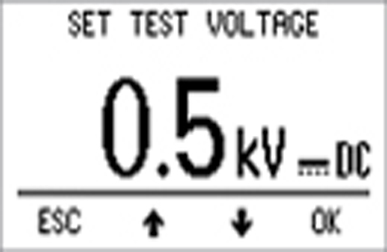

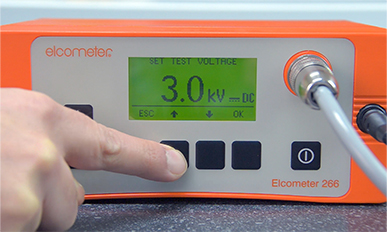

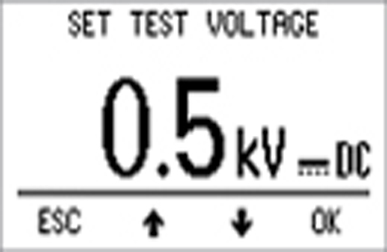

可调电压

用小键盘调节电压,不需螺丝刀:0.5kV - 1kV 间隔 50V, 1kV - 30kV 间隔 100V。用仪器上的小键盘来调节电压,无需螺丝刀。对于半导电的涂层,电流灵敏度可手工预设或由仪器自动调节。

内部电压表/电压交验装置

内部电压计/Jeep检验仪确保所选电压就是测试电压。内部校准的jeep检验仪和闭路系统保证测试电压经过了精确测试和持续控制,而不管气候条件如何。

可互换的探头手柄

可互换的探头手柄:, 5kV, 15kV和 and 30kV D C(直流)版本可供选择。

声音和可视警报

检测到裂缝后产生声音和可视报警。手柄带有明亮的 LED指示灯和大声的报警,清晰指示仪器处于工作状态(红灯)或者测到了火花(蓝灯)。

电池包

电池包可在主机内或主机外充电,以备连续使用。可充电电池包能在主机内或主机外充电。电池 4个小时即可冲完,每次充电后可连续使用长达40个小时。

通用探头适配器

使易高266能够与所有主要的电火花检测仪的附件配合使用。

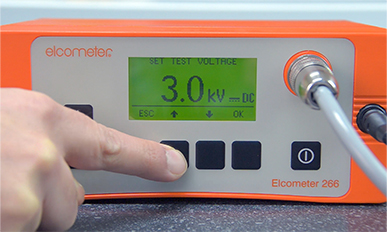

屏幕显示

大的背光显示即使暗黑环境也清晰可见。当检测到裂缝时背景光也会闪烁。

辅助手柄

可选项手柄适合于双手操作,安全性依然很高。适用于测试管道和水槽地面。

Elcometer 266 安全特性

- 手柄上有双重安全开关,可避免误开机。 两级安全开关确保当 266的手柄没有握在手中的时候,手柄是关机状态。

- 特制的螺纹手柄保护性更强,而可选项手柄适用于两手操作 加宽螺纹手柄可以保护使用者,是为满足EN61010标准而特殊设计的。做到了最安全的高压测试。

- 仪器的扬声器清晰地发出嘀嘀声,提示手柄处有电压。

- 检测到电火花时会有大音量的警报声发出来。报警音量可以调节,确保在嘈杂环境下也能听到。

-

- 技术信息

-

附件Elcometer 266 DC (直流)电火花检漏仪

产品描述 部件编号 证书 Elcometer 266* D266----4

高压输出精确度 ±5%或1000V以下是±50V 操作温度 0°C 至 50°C (32°F至 120°F) 电源 充电电池包;电池4小时内充满电 测到的电流精确度 全部范围的±5% 输出电流: 0 - 100µA最大 典型电池寿命——背光关闭(开启) DC5: 40 (20) 小时

DC15: 20 (15) 小时

DC30: 10 (8) 小时仪器包装箱、尺寸 防水,ABS材质包装箱;520 x 370 x 125mm (20.5 x 14.5 x 5”) 重量 主机(含电池包):1.2kg (2.7lb), 手柄 :0.6kg(1.3lb) 包装清单 易高266直流电火花检测仪主机, 电池包, 高压手柄的卷曲连线, 10m (32’) 接地 信号反馈线, 电池充电器带英国, 欧洲, 美国和澳大利亚插头, 带状刷,肩带,坚 硬的塑料手提箱和操作手册 * Elcometer 266 标配不包含探头手柄。点击附件选项卡, 了解更多信息。

○ 可选择提供校准证书

-

- 标准

-

标准Elcometer 266 DC (直流)电火花检漏仪

ANSI/AWWA C213, AS 3894.1, ASTM C 536, ASTM C 537, ASTM D 4787, ASTM D 5162-B, ASTM G 62-B, BS1344-11, DIN 55670, EN 14430, ISO 2746, ISO 29601, JIS K 6766, NACE RP0274, NACE RP0188, NACE RP0190, NACE RP0490, NACE SP0188, NACE SP0490

灰色是已经被取代但在一些行业内仍被认可的标准。

-

- 下载

-

下载

- 部件编号

-

部件编号Elcometer 266 DC (直流)电火花检漏仪No data found!!

-

Elcometer 266 DC (直流)电火花检漏仪

Elcometer 266 DC (直流)电火花检漏仪- 部件编号 : D266----4

-

Elcometer 266 Holiday Detector

Elcometer 266 Holiday Detector- 部件编号 : D266----4C

- 技术规格

-

技术规格Elcometer 266 DC (直流)电火花检漏仪

部件编号: T26620033-1

部件编号: T26620033-1 部件编号: T26620033-2

部件编号: T26620033-2 部件编号: T26620033-3

部件编号: T26620033-3 部件编号: T26620033-4

部件编号: T26620033-4 部件编号: T26620081

部件编号: T26620081 部件编号: T26620033-1C

部件编号: T26620033-1C 部件编号: T26620033-2C

部件编号: T26620033-2C 部件编号: T26620033-3C

部件编号: T26620033-3C 部件编号: T26620033-4C

部件编号: T26620033-4C

-

- Home

- Elcometer 266 DC (直流)电火花检漏仪

Elcometer 266 DC (直流)电火花检漏仪

- 防护涂料

Elcometer266给高压直流测试涂层孔隙带来革命性的变化,检测比以往任何时候更加安全,方便,可靠。

- 概要

- 产品特点

- Package Selector

- 技术信息

- Application Guides

- 标准

- 部件编号

- 视频

- 技术规格

- 下载

- Elcometer 266

界面友好

电压计算器根据涂层厚度值自动设置正确的电压。无需使用查找表。

安全

手柄上有一个双安全开关,可以避免意外接通和 专用的罗纹,提供卓越的保护。

万能

要更改最大电压范围,请选择其他手柄; 5kV,15kV或30kV DC或30kV DC连续。

概要

Elcometer 266 DC (直流)电火花检漏仪

易高266电火花检漏仪可以用来测试达7.5mm(300mils)厚的涂层孔隙, 是理想管道上涂层和其他保护涂层的检测.

这个检漏仪具有一个内置电压计算器, 确定和设置基于所述测试标准和被测试涂层的厚度正确的测试电压。

主要特点

Elcometer 266 DC (直流)电火花检漏仪

- 电压计算器功能自动根据涂层厚度值来设定电压

- 可调电压:

- 0.5kV - 1kV:间隔50V

- 1kV - 30kV: 间隔100V

- 手柄上的双重安全开关, 以避免意外的开关(只有灰/橙探头手柄)

- 内部电压交验仪确保所选电压就是测试电压

- 可视和声音报警手柄上的LED和大声的报警,清晰提示检测到孔隙

- 要改变最大电压范围, 选择不同的手柄; 5kV, 15kV或30kVDC或30kV DC连续

- 多种探头刷和弹簧可使用

易高266 DC电火花检漏仪特点说明

电压计算器

电压计算功能自动根据涂层厚度值来设定电压。带内置式电压计算器,无需查看换算表。输入测试标准和涂层厚度,仪器会自动算出正确的电压。

可调电压

用小键盘调节电压,不需螺丝刀:0.5kV - 1kV 间隔 50V, 1kV - 30kV 间隔 100V。用仪器上的小键盘来调节电压,无需螺丝刀。对于半导电的涂层,电流灵敏度可手工预设或由仪器自动调节。

内部电压表/电压交验装置

内部电压计/Jeep检验仪确保所选电压就是测试电压。内部校准的jeep检验仪和闭路系统保证测试电压经过了精确测试和持续控制,而不管气候条件如何。

可互换的探头手柄

可互换的探头手柄:, 5kV, 15kV和 and 30kV D C(直流)版本可供选择。

声音和可视警报

检测到裂缝后产生声音和可视报警。手柄带有明亮的 LED指示灯和大声的报警,清晰指示仪器处于工作状态(红灯)或者测到了火花(蓝灯)。

电池包

电池包可在主机内或主机外充电,以备连续使用。可充电电池包能在主机内或主机外充电。电池 4个小时即可冲完,每次充电后可连续使用长达40个小时。

通用探头适配器

使易高266能够与所有主要的电火花检测仪的附件配合使用。

屏幕显示

大的背光显示即使暗黑环境也清晰可见。当检测到裂缝时背景光也会闪烁。

辅助手柄

可选项手柄适合于双手操作,安全性依然很高。适用于测试管道和水槽地面。

Elcometer 266 安全特性

- 手柄上有双重安全开关,可避免误开机。 两级安全开关确保当 266的手柄没有握在手中的时候,手柄是关机状态。

- 特制的螺纹手柄保护性更强,而可选项手柄适用于两手操作 加宽螺纹手柄可以保护使用者,是为满足EN61010标准而特殊设计的。做到了最安全的高压测试。

- 仪器的扬声器清晰地发出嘀嘀声,提示手柄处有电压。

- 检测到电火花时会有大音量的警报声发出来。报警音量可以调节,确保在嘈杂环境下也能听到。

附件Elcometer 266 DC (直流)电火花检漏仪产品描述 部件编号 证书 Elcometer 266* D266----4

高压输出精确度 ±5%或1000V以下是±50V 操作温度 0°C 至 50°C (32°F至 120°F) 电源 充电电池包;电池4小时内充满电 测到的电流精确度 全部范围的±5% 输出电流: 0 - 100µA最大 典型电池寿命——背光关闭(开启) DC5: 40 (20) 小时

DC15: 20 (15) 小时

DC30: 10 (8) 小时仪器包装箱、尺寸 防水,ABS材质包装箱;520 x 370 x 125mm (20.5 x 14.5 x 5”) 重量 主机(含电池包):1.2kg (2.7lb), 手柄 :0.6kg(1.3lb) 包装清单 易高266直流电火花检测仪主机, 电池包, 高压手柄的卷曲连线, 10m (32’) 接地 信号反馈线, 电池充电器带英国, 欧洲, 美国和澳大利亚插头, 带状刷,肩带,坚 硬的塑料手提箱和操作手册 * Elcometer 266 标配不包含探头手柄。点击附件选项卡, 了解更多信息。

○ 可选择提供校准证书标准Elcometer 266 DC (直流)电火花检漏仪ANSI/AWWA C213, AS 3894.1, ASTM C 536, ASTM C 537, ASTM D 4787, ASTM D 5162-B, ASTM G 62-B, BS1344-11, DIN 55670, EN 14430, ISO 2746, ISO 29601, JIS K 6766, NACE RP0274, NACE RP0188, NACE RP0190, NACE RP0490, NACE SP0188, NACE SP0490

灰色是已经被取代但在一些行业内仍被认可的标准。

部件编号Elcometer 266 DC (直流)电火花检漏仪No data found!!-

Elcometer 266 DC (直流)电火花检漏仪

Elcometer 266 DC (直流)电火花检漏仪- 部件编号 : D266----4

-

Elcometer 266 Holiday Detector

Elcometer 266 Holiday Detector- 部件编号 : D266----4C

技术规格Elcometer 266 DC (直流)电火花检漏仪 部件编号: T26620033-1

部件编号: T26620033-1 部件编号: T26620033-2

部件编号: T26620033-2 部件编号: T26620033-3

部件编号: T26620033-3 部件编号: T26620033-4

部件编号: T26620033-4 部件编号: T26620081

部件编号: T26620081 部件编号: T26620033-1C

部件编号: T26620033-1C 部件编号: T26620033-2C

部件编号: T26620033-2C 部件编号: T26620033-3C

部件编号: T26620033-3C 部件编号: T26620033-4C

部件编号: T26620033-4C

- 部件编号

-