Why Measure Wet Film Thickness?

The ability to measure the wet film thickness is important for financial, logistical and quality reasons. The immediate benefit is that the operative applying the coating is provided with instant feedback on the quality of the job they are doing. This enables any corrections to be made as and when they become necessary.

70% of the total cost of re-painting a structure is gaining access to that structure with hoists, scaffolding etc. (mobilisation). As the total cost would be incurred again if the painters are required to re-coat the structure, or parts of it, it is more efficient to check the thickness of paint applied and make any necessary adjustment before they leave.

Too much or too little coating can cause quality issues. If the coating is too thin because not enough paint has been applied, then profile peaks may remain exposed and instant corrosion can take place. This is known as rust rash.

Even if the profile peaks are covered, reduced protection will be given by a thin coating. This will happen particularly in service applications where the coating has eroded during its lifetime, resulting in either premature failure or reduced wear resistance. This is common in ship hulls, pipelines and internal coatings.

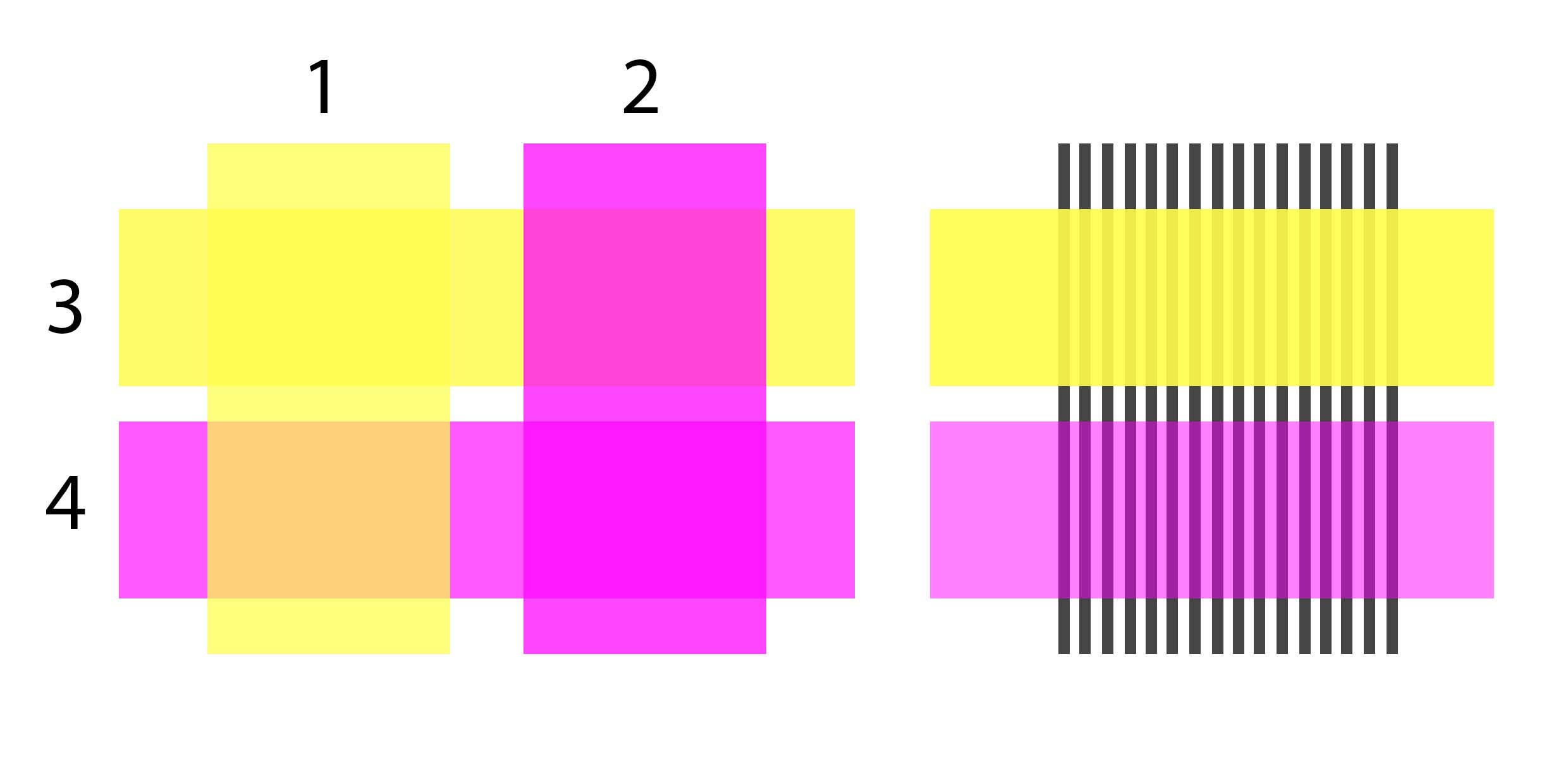

Additionally, if the paint applied is too thin, the surface will not be covered sufficiently and the original surface may be visible through it. The ability of a coating to cover the surface is known as the hiding power.

Figure 7 shows the relative hiding power of the two paints. In the left-hand diagram, the pink hides the yellow better than yellow covers the pink. However, the yellow hides the black lines better than the pink does.

If the paint is applied too thickly, then more paint than necessary is being used, thus increasing cost. The top surface of the paint will dry more quickly than that below the surface, as it is easier for the volatile components to evaporate off the surface. If the paint is too thick, enough of the volatile component will have evaporated for a skin to form whilst the paint below the surface is still uncured.

This skin will then prevent the remaining volatile component from evaporating easily, leaving much of the paint uncured. This will reduce the adhesion and therefore the performance of the coating. This is called solvent entrapment. Furthermore, as a coating dries, it shrinks, which may cause the skin to crack. This can lead to moisture ingress and subsequent premature coating failure.

Measuring the wet film thickness, therefore, gives an early indication of the quality of the coating application. This enables correction at the most convenient and cost-effective time. It is important to measure the wet film thickness immediately after the coating is applied.

Knowing the wet film thickness also enables us to predict the dry film thickness.

How Elcometer Can Help With Wet Film Thickness

If you've read our guide on measuring wet film thickness and are looking to start measuring, browse our ranges of wet film thickness tools.

Alternatively, if you've got any questions around taking your own wet film thickness measurements, you can get in touch with our team of experts for support.