How to choose the correct Dry Film Thickness probe for your application

When measuring dry film thickness using a digital coating thickness gauge, incorrect probe choice can result in measurement failure and possible inaccurate results.

Choosing the correct probe to ensure accurate and repeatable results is not difficult – although there are several factors to consider with many different probe designs and ranges available. The choice, however, is highly dependent on the job that is being undertaken.

Ferrous or Non Ferrous

The first major consideration is the material of the substrate being measured and the dry film gauge being used.

Digital coating thickness gauges are designed to measure on ferrous or non-ferrous metal substrates– meaning they will only measure the thickness of coatings on these materials. As might be expected, ferrous probes (F) measure coatings on ferrous metal substrates and non-ferrous probes (N) on non-ferrous metal substrates. There are also FNF probes which will measure on either.

Scales

The next factor to consider is the coating thickness range of the probe. Coating thickness probes are designed to measure specific thicknesses, making them more accurate. For example, the Elcometer dry film thickness probe range uses the following scales:

- Scale 0.5: 0-500μm / 0-20mils

- Scale 1: 0-1500μm / 0-60mils

- Scale 2: 0-5mm / 0-200mils

- Scale 3: 0-13mm / 0-500mils

- Scale 6: F: 0-25mm / 0-980mils N: 0-30mm / 0-1,200mils

- Scale 7: 0-31mm / 0-1,220mils

All Elcometer paint meter probes are supplied with a Test Certificate and a set of calibration foils, appropriate to the scale range of the probe.

Probe Shape

The most commonly used probe is the Standard Straight probe which is suitable for measuring on flat or curved surfaces - ideal for inspecting easily accessible areas with plenty of headroom.

However, if the measurement location has restricted clearance, such as inside pipes, an angled probe would be a better choice. Elcometer’s range of coating thickness probes include 90° and 45° options.

When measuring edges or narrow areas, a probe with a smaller sample diameter may be necessary. Elcometer’s range of mini probes require a minimum sample diameter of just 3mm, enabling the accurate inspection of small, tight spaces.

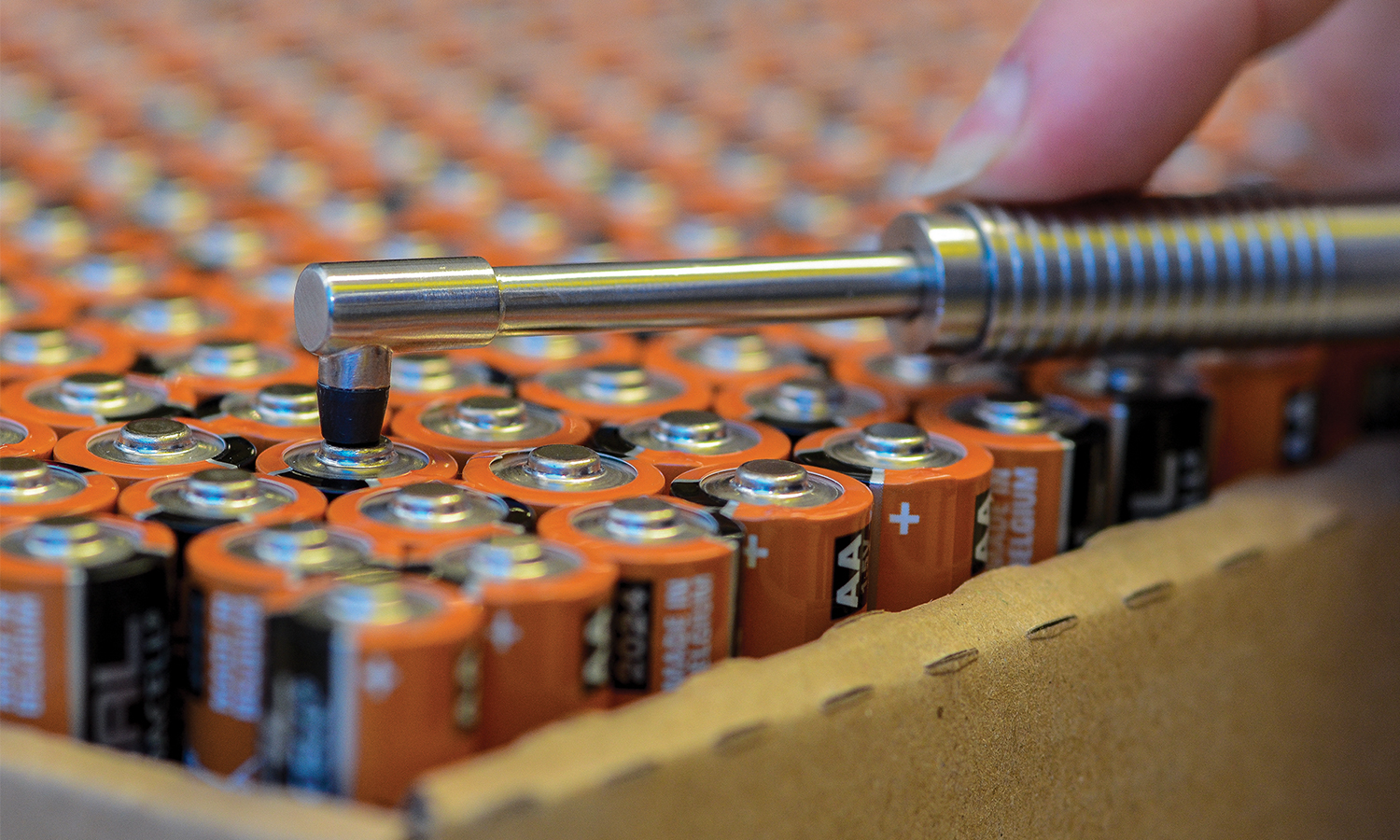

When measuring areas with restricted access, Elcometer’s telescopic probes provide a safe solution. They can be extended to a length of up to 122cm (48”).

For jobs that require single-handed inspection, when using rope access for example, the PINIP™ probe is ideal. PINIP™ probes are plug-in probes that convert a separate coating thickness gauge into an integral gauge. High temperature PINIP™s also exist for measurement on hot surfaces up to 250°C (480°F), which would otherwise damage the probe.

Scan Probes

Scan probes significantly reduce dry film thickness inspection times without affecting accuracy. They enable users to rapidly scan large surface areas - without damaging the probe or coating. The Elcometer 456 Scan Probe can take in excess of 140 readings every minute.

As well as the standard scan probe, Elcometer also offer a ‘Roller Bearing Scan Probe’ which is ideal for the measurement of abrasive coatings and pre-construction primers on large structures.

Specialised Probes

Elcometer offer a range of specialist probes uniquely suited to specific applications. The range includes anodising probes which can be dismantled for easy cleaning, ideal for the anodising environment.

Waterproof probes are also available from Elcometer; these probes are sealed for use underwater, for accurate and easy thickness measurements, even when using diving gloves.

The soft coating probes for soft materials are HVCA approved and designed for controlling ducting deposits and monitoring their build-up - essential for maintaining hygiene standards and reducing fire risks in heating and ventilation systems.

Elcometer’s range of film thickness probes are also available with heavy duty armoured cables to reduce the risk of cable damage when being used in hazardous areas.

Probe Choice

Elcometer provide a range of over 60 different fully interchangeable probes for the Elcometer 456 Coating Thickness Gauge, available in a number of designs and scale ranges to provide a solution for all inspection requirements, whatever and wherever they might be.

The team at Elcometer are on-hand to provide expert technical advice to assist in making the best choice for the application. And with a global network of offices, training centres, distribution centres and distributors, all expertly trained, Elcometer are able to provide full after sales service and support, worldwide.

For more information on the Elcometer Range of Coating Thickness Probes

For more information on the Elcometer 456 Separate Coating Thickness Gauge