Pulsed DC Holiday Detection

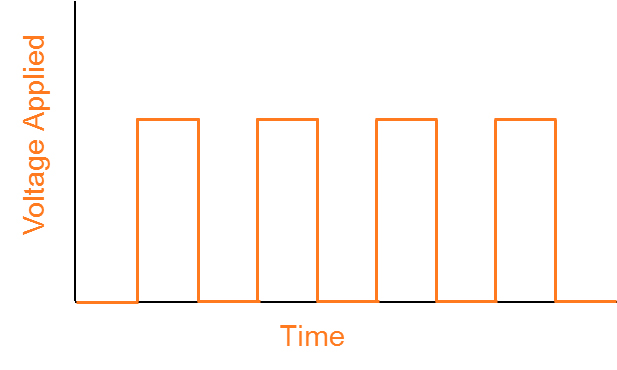

An alternative to continuous DC is pulsed DC. Pulsed DC (voltage) is a time dependent voltage signal with defined periods of when a specified voltage is applied, alternated with periods of no applied voltage. Effectively, the applied voltage is repeatedly turned on and off, many times per second.

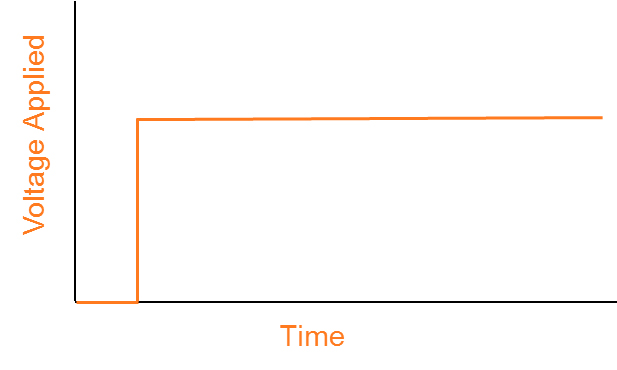

Continuous DC (voltage) is a voltage level of unvarying, time independent nature caused by direct current (DC) flow. The word ‘continuous’ is used to reinforce the unchanging character and so differentiated from Pulsed DC.

Direct substrate to ground contact is not required

As a pulsed DC system does not need the direct substrate to ground contact that a continuous DC system requires, it can be used with a trailing lead.

This means that you do not always need to connect the earth cable to the component substrate – ideal in many test situations such as testing on large surface areas, on pipelines or inside tanks.

Pulsed DC systems can be used on damp or dirty surfaces

Using pulsed DC technology, the Elcometer 280 Pulsed DC Holiday Detector is designed to ensure that the energy is contained within very short pulses, each pulse having more energy than an equivalent continuous DC system. This means that the Elcometer 280 can be used to test for holidays over slightly conductive coatings, or dirty or damp surfaces. Since the technique is pulsed, telegraphing is often prevented.

As pipeline coatings are mainly applied in thick, continuous layers on new pipelines in the field, the use of a pulsed DC holiday detector to detect flaws in coatings applied to new pipeline constructions is preferred to the continuous DC system.

The signal return cable for the pulsed DC method does not have to be connected directly to the conductive substrate as is the case with the continuous DC holiday detectors.

It is also necessary to survey the condition of the coating during the service life of a pipeline and the pulsed DC method also offers some advantages for testing coatings that have been in service, whereas the continuous DC technique is mainly limited to newly applied coatings.