Measuring Temperature, Relative Humidity & Dewpoint

Along with surface temperature (Ts) and air temperature (Ta), it’s also important to measure the liquid temperature to establish if the coating has been stored at the appropriate temperature and it’s at the correct viscosity for application. There are many types of thermometers to measure liquid temperature, and some have been modified for specific measuring applications.

Measuring Liquid Temperature

To ensure the coating is at the right temperature for application, liquid thermometers like the Elcometer 210 Paint Thermometer should be used. Unlike the traditional liquid-filled glass thermometers, the Elcometer 210 Paint Thermometer is constructed out of metal, making it ideal for on-site measurements.

Other available thermometers range from a simple pocket-sized liquid thermometer, such as the Elcometer 212 which has an integrated needle probe that folds into the case of the thermometer; to gauges which have a k-type thermocouple connection, such as the Elcometer 213, allowing any k-type thermocouple probe to be attached.

Measuring Surface Temperature (Ts)

When measuring the surface temperature on steel, magnetic thermometers like the Elcometer 113 Magnetic Thermometers, can provide a continuous indication of the surface temperature. These thermometers incorporate a bi-metallic strip and therefore require time to adjust to the temperature.

More advanced gauges, like the Elcometer 319 Dewpoint Meter, not only measure the full range of key climate parameters but also have a k-type connection to allow for external probes (Te), such as liquid or surface temperature probes, to be connected.

Gauges using k-type thermocouple-based thermometers for measuring liquid temperatures can also be used to measure the surface temperature – when a surface temperature probe is fitted. It’s important to note that, with all thermocouple-based thermometers, there is a short period of time required to allow the temperature to stabilise. Care should be taken to ensure that the gauge reading has settled before removing the temperature sensor. Some gauges have a digital indicator to help determine when the temperature reading has stabilised.

Non-contact thermometers, such as the Elcometer 214L Infrared Digital Laser Thermometer are also available. These IR (infrared) laser thermometers enable surface temperature to be measured very quickly with no contact required.

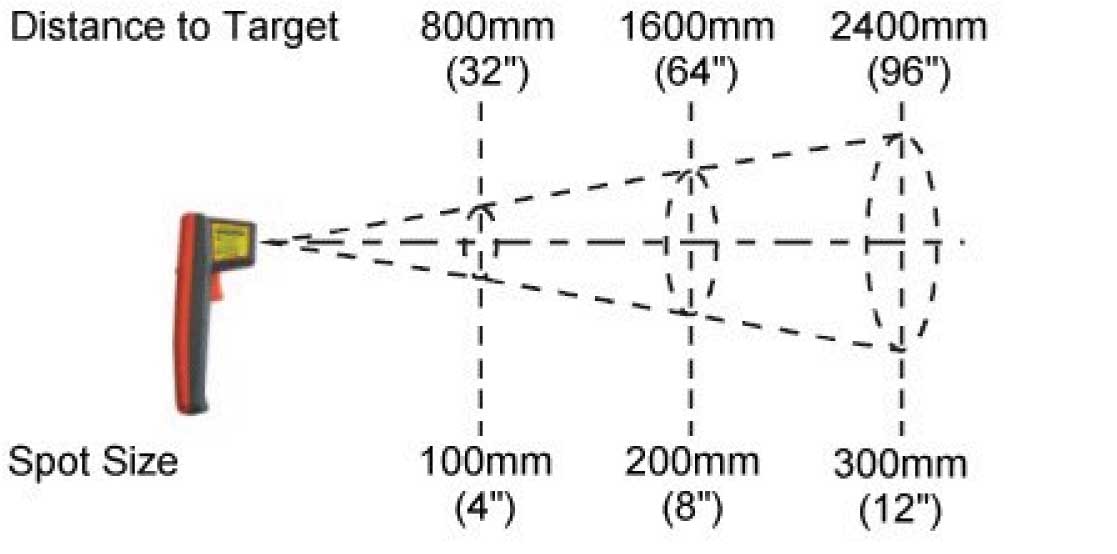

The Elcometer 214L Digital Laser Thermometer has a laser pointer which displays the centre of the point of measurement. It’s very important to note that IR thermometers provide the average temperature over a measured area – it is not a spot measurement device. The measured area is determined by the distance the gauge is away from the surface being measured and the distance to target ratio of the gauge itself.

The Elcometer 214L IR Digital Laser Thermometer has a D/T (Distance-to-Target) ratio of 8:1. This means that it measures the emitted energy (surface temperature) from a target spot, one-eighth the size of the working distance. As can be seen in the diagram, if the distance from the sensor optics to the target is 200mm (8”), the diameter of the measured area is 25mm (1”). However, if the IR thermometer is 2.4m (96”) away, the ‘spot’ size (the area which the gauge provides the average temperature over) is greatly increased to 300mm (12”).

IR thermometers are ideal for a quick, approximate answer in situations where the item being measured is moving and contact measurement is not possible. When it is required to establish the surface temperature of a localised area, either a contact thermometer should be used, or the IR thermometer should be moved closer to the assessment surface.

Measuring the Air Temperature (Ta)

It’s very easy to establish the temperature of the air. Simply hold a thermometer and measure the temperature. Although it sounds simple, inaccuracies can occur as your body (or hand) may generate heat and sunlight can cause the gauge to provide a different temperature to the actual air temperature.

Air temperature can either be measured with a special air temperature probe connected to a digital gauge or by using a whirling hygrometer (often referred to as a sling psychrometer). Special air temperature probes, such as the Elcometer 319 Dewpoint Meter, have digital sensors which are designed to minimise the effects of external heat by being positioned away from the hand or on a separate sensor. The sensors are also typically protected by a perforated white cap to reflect solar heat.

Whirling hygrometers consist of two liquid-filled thermometers positioned side by side in a rotating frame. One is covered with a fabric “sock” while the other is uncovered. The operator rotates the whirling hygrometer at a defined, uniform speed. The uncovered thermometer reading is the air temperature (Ta).

Care should be taken using this method to determine Ta as there could be a variation (particularly in high humidity environments) between the static air temperature and the whirling hygrometer uncovered thermometer.

Measuring Wet Bulb (Twb) and Dry Bulb (Tdb) Temperatures

Whirling hygrometers are more typically used to measure wet bulb (Twb) and dry bulb (Tdb) temperatures. These two temperatures can then be used to determine the relative humidity (RH). These gauges consist of two liquid-filled thermometers, one with and one without a fabric ‘sock’ or ‘wick’.

The fabric sock is saturated with distilled water and the gauge is whirled (spun around) for 20-40 seconds. The thermometer is quickly read, and the gauge is spun again. Once again, the themometer is read. This is repeated until there are two consecutive readings that are the same.

Once two consecutive wet bulb temperatures are recorded as the same, then this consistent measurement is the wet bulb temperature (Twb). The dry bulb temperature (Tdb) is recorded in the same way with the uncovered thermometer. The wet bulb depression can then be calculated. This is the difference between Tdb and Twb.

Measuring Relative Humidity (RH) & Dewpoint (Td) Temperature

Relative humidity and dewpoint are calculated from other connected parameters. As the hygrometer whirls through the air, the water on the fabric evaporates, cooling the thermometer bulb. This works in the same way as perspiration cools the skin when it evaporates. The rate at which the water evaporates, and the amount of cooling is defined by the level of humidity in the air.

The lower the humidity, the faster the evaporation rate and the greater the cooling of the bulb. The higher the humidity, the slower the evaporation rate hence the bulb is cooled to a lesser degree. The wet bulb will register a lower temperature than the dry bulb in air that has a relative humidity (RH) between 0% -100%.

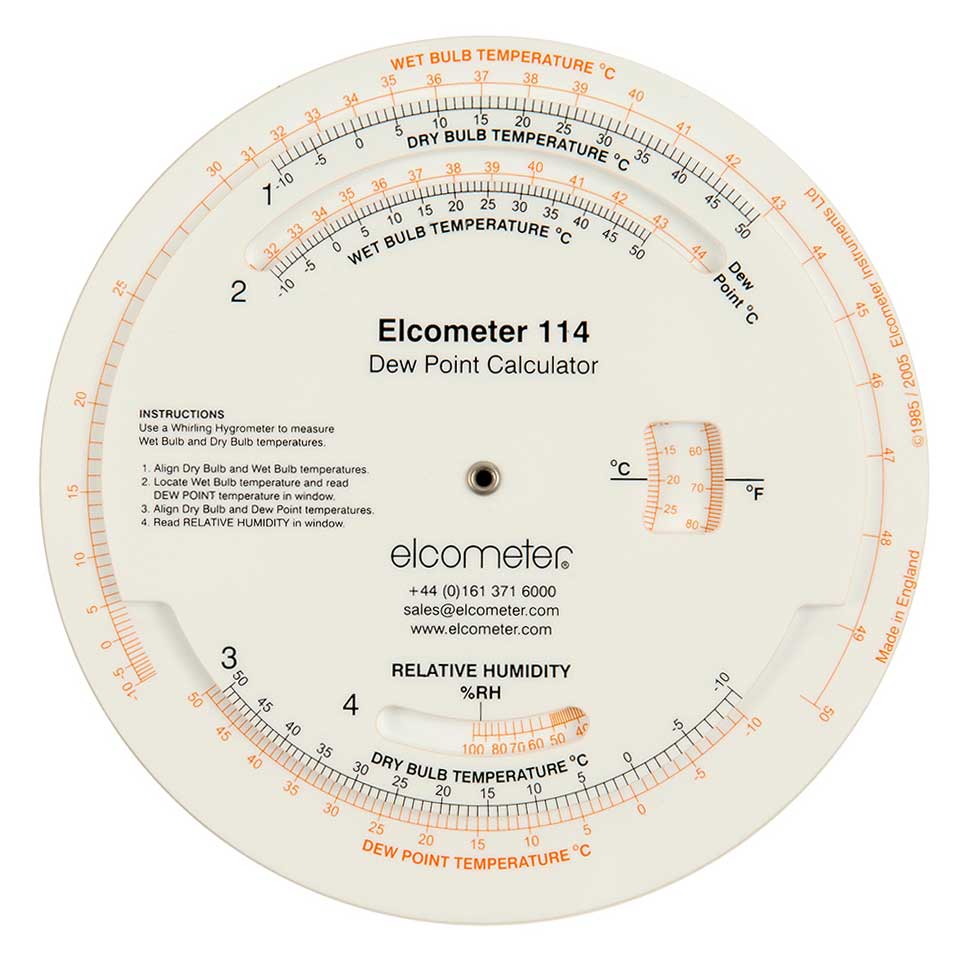

Whilst tables can be used to determine the %RH, conversion discs, like the Elcometer 114 Dewpoint Calculator not only provide the %RH, but can also provide the dewpoint temperature (Td).

Determining the %RH using an Elcometer 114 Dewpoint Calculator:

- Align the wet bulb temperature (Twb) to the dry bulb temperature (Tdb).

- Read the measurement off the 'dewpoint temperature' (Td) at the point identified by the wet bulb temperature.

Having determined the dewpoint temperature (Td), using the lower part of the calculator:

- Align the dewpoint temperature (Td) determined in step 2, with the dry bulb temperature (Tdb).

- Read off the relative humidity (%RH).

Note: Typically, dewpoint calculators are designed to use temperatures in degrees Celcius (°C). To help calculate the dewpoint and relative humidity whilst using degrees Fahrenheit (°F) there is a temperature convertor in the middle of the calculator.

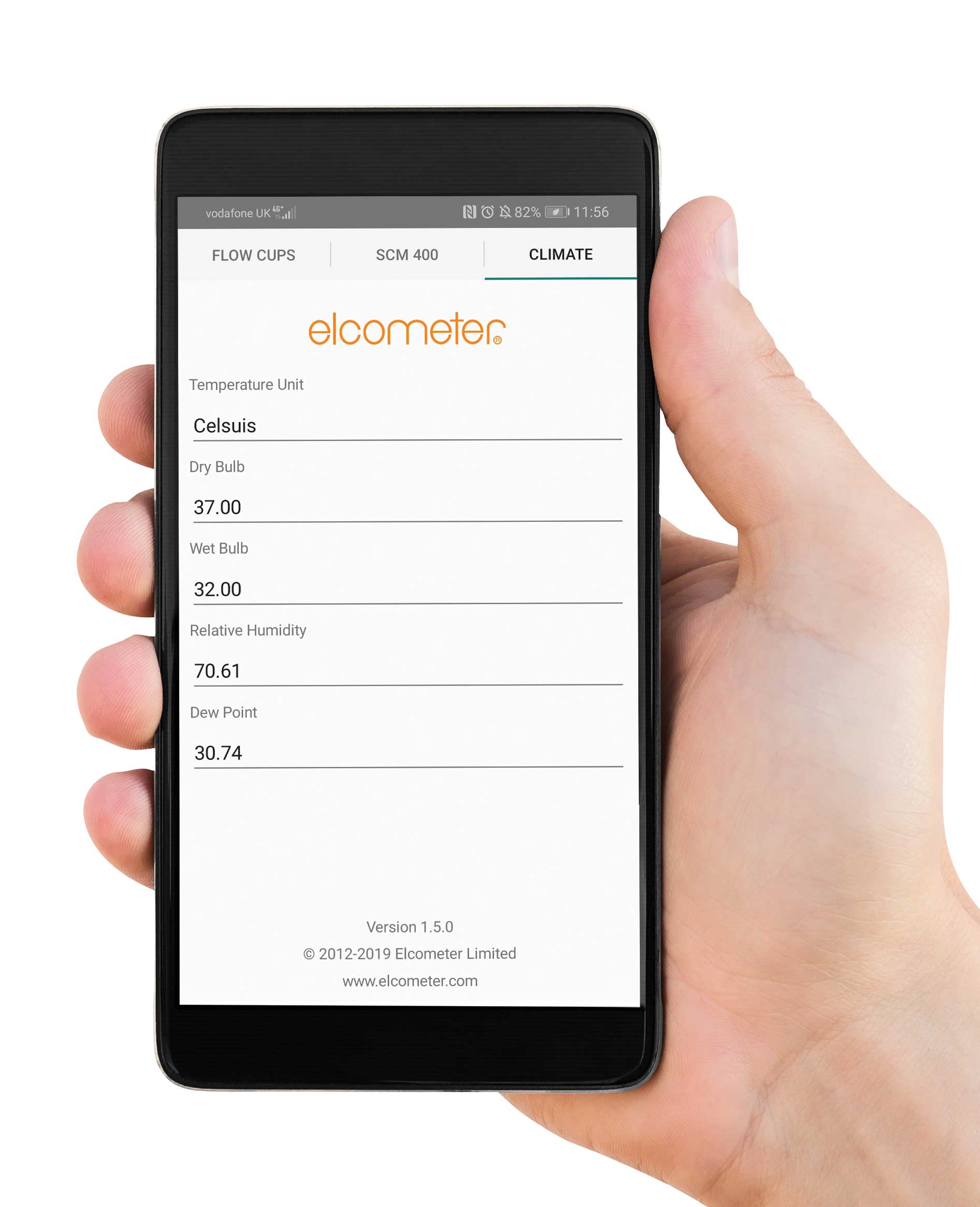

Determining the %RH using ElcoCalc:

To save time, the ElcoCalc app can be installed on to a smart phone. ElcoCalc allows you to input the dry bulb and bet bulb measurements and the relative humidity and dewpoint results will instantly appear. Temperatures can be inputted in either degrees Celsius (°C) or degrees Fahrenheit (°F). The app is free to download on Android and Apple devices and can be found in the Play Store and App Store.

Whilst whirling hygrometers provide a good indication of the atmospheric conditions, due to their design, they do not provide the coating inspector with the localised data of the conditions at the surface of the substrate which is to be coated.

Delta T (TΔ) is the primary climate parameter within the coatings industry.

This means that the dewpoint temperature should be determined as close to the surface temperature measurement (taken on the substrate to be coated). Whirling a hygrometer in the general area may be “good enough” but could provide the inspector with a false positive – allowing the coating to be applied when it shouldn’tbe.

Historically, whirling hygrometers used mercury-filled thermometers to determine Twb and Tdb. Due to international laws banning the use of mercury in thermometers, spirit thermometers are now used.

Unlike mercury thermometers, spirit thermometers are more susceptible to pressure and other atmospheric conditions. This means whirling hygrometers today are not as accurate as they once were.

Instead of using hygrometers’ conversion discs and charts, there are gauges on the market which will take all the measurements and perform all the calculations for us – like the Elcometer 319 Dewpoint Meter for example. These simple to use digital gauges will measure and often record climatic parameters such as:

- RH – % Relative Humidity

- Ts – Surface Temperature

- Ta – Ambient Air Temperature

- Td – Dewpoint Temperature

- TΔ – Delta T (difference between Td & Ts)

- Tdb – Dry Bulb Temperature

- Twb – Wet Bulb Temperature

The Elcometer 319 Dewpoint Meter is equipped with an air temperature and humidity probe, a surface temperature probe and an external k-type socket. The socket enables a connection of k-type accessories, like a Magnetic Surface Temperature Probe, allowing the user to continuously monitor and record the key climatic parameters required by a coating inspector.

A typical coating application specification may require the temperature of the surface to be coated be at least 3°C (5°F) above the dewpoint temperature and the relative humidity should not exceed 85%. Furthermore, the temperature of the substrate and the air should be between -5°C (23°F) and +40°C (104°F).

All these values are presented on the display of the Elcometer 319 Dewpoint Meter and, for the example given, the coating may be applied in accordance with the manufacturer’s recommendations.

Remote Climate Monitoring

The Elcometer 319 Dewpoint Meter can also be used as a remote device, mounted magnetically on the substrate, logging data at pre-programmed intervals.

This data can be downloaded to a PC or mobile device via USB or Bluetooth for further analysis. It can also be used to allow remote real-time monitoring using the versatile ElcoMaster software package.

On the gauge display, the trend of the parameter values is displayed using up and down arrows. With each parameter that the gauge measures or calculates, it is possible to set upper and lower alarm limits. If the measured or calculated value exceeds the set limit, then an audible alarm sounds and a visible alarm, a red light, flashes on the unit. In the display, the icon of the parameter that has exceeded the limit flashes.

Specialised Gauges for Specific Regions

Whilst the parameters discussed above will always be relevant to the application of a coating, some users may only be interested in knowing the value of one or two of these parameters.

As discussed earlier,the two key climatic parameters for most coatings inspectors are delta T (TΔ) and relative humidity (RH) as these are the two values that are typically quoted on a coating’s datasheet. For these users, the Elcometer 309 Delta T Hygrometer has been developed.

If the user is in a particularly hot climate, then, in addition to the relative humidity, it is the surface temperature (Ts) which is often of more importance than the dewpoint temperature as the coating should not be applied to a surface that is too hot. The Elcometer 308 Hygrometer provides these two key measurement parameters.

For Support with Measuring Climatic Conditions

As world leaders in providing inspection equipment to the protective and industrial coatings industries, accuracy, reliability and efficiency is at the heart of every single piece of our equipment.

To find out more about our complete range of dewpoint and relative humidity meters, thermometers, dataloggers, moisture meters and anemometers, visit our Coating Inspection Division page.