Elcometer 3230 Coil Coating Wet Film Wheels

- Protective Coatings

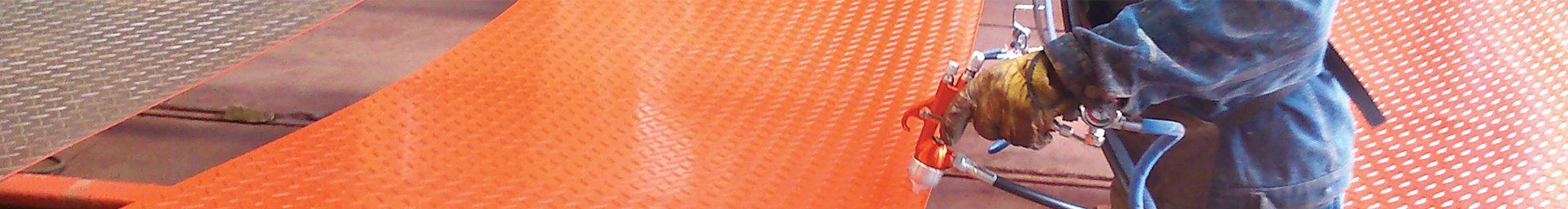

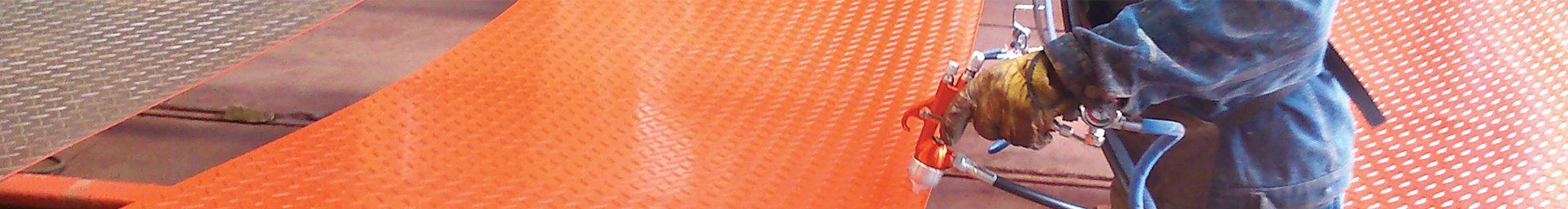

These Elcometer 3230 Coil Coating Wet Film Wheels are high precision, accurate and easy to use instruments that are designed for use in the coil coating process.

- Summary

-

Summary

-

The outer wheels are knurled to allow measurements to be taken on slippery coatings or on fast moving substrates.

By rolling the gauge through a wet coating, the centre wheel eventually touches the film. This point on the scale indicates the thickness.

When the volume to solids ratio of the coating is known (generally found on the product data sheet supplied by the manufacturer), the wet film thickness can be used to predict the dry film thickness.

-

- Technical Information

-

Technical SpecificationElcometer 3230 Coil Coating Wet Film Wheels

Part Number Range Graduations Certificate Metric Film Wheels K0003230M017 0 - 50μm 2.5μm

K0003230M018 0 - 100μm 5.0μm

Imperial Film Wheels K0US3230M017 0 - 2mils 0.1mils

K0US3230M018 0 - 4mils 0.2mils

Dimensions 50 x 30mm (1.97 x 1.18”) Weight 220g (7.76oz) Packing List Coil Coating Wet Film Wheel, storage case and operating instructions Part Number Dimensions Certificate Metric Film Wheels K0003230M017 0 - 50μm

Weight 2.5μm K0003230M018 0 - 100μm

Weight 5.0μm Imperial Film Wheels K0US3230M017 0 - 2mils

Weight 0.1mils K0US3230M018 0 - 4mils

Weight 0.2mils Dimensions 50 x 30mm (1.97 x 1.18”) Weight 220g (7.76oz) Packing List Coil Coating Wet Film Wheel, storage case and operating instructions ○ Optional Calibration Certificate available.

-

- Standards

-

StandardsElcometer 3230 Coil Coating Wet Film Wheels

ASTM D 1212-A, AS/NZS 1580.107.3, BS 3900-C5-7A, ISO 2808-1B, ISO 2808-7A, JIS K 5600-1-7, NF T30-125

Standards in grey have been superseded but are still recognised in some industries.

-

- Downloads

-

Downloads

- Part Numbers

-

Part NumbersElcometer 3230 Coil Coating Wet Film WheelsNo data found!!

-

Elcometer 3230 Coil Coating Wet Film Wheel

Elcometer 3230 Coil Coating Wet Film Wheel- Range: 0 - 50μm

- Part Number : K0003230M017

-

Elcometer 3230 Coil Coating Wet Film Wheel

Elcometer 3230 Coil Coating Wet Film Wheel- Range: 0 - 100μm

- Part Number : K0003230M018

-

Elcometer 3230 Coil Coating Wet Film Wheel

Elcometer 3230 Coil Coating Wet Film Wheel- Range: 0 - 2mils

- Part Number : K0US3230M017

-

Elcometer 3230 Coil Coating Wet Film Wheel

Elcometer 3230 Coil Coating Wet Film Wheel- Range: 0 - 4mils

- Part Number : K0US3230M018

- Accessories

-

AccessoriesElcometer 3230 Coil Coating Wet Film Wheels

Part Number: KT003230N003

Part Number: KT003230N003 Part Number: KT003230N002

Part Number: KT003230N002

Welcome to Elcometer.tv

Your ultimate training channel

- Home

- Coatings Inspection

- Coatings Inspection Division

- Wet Film & Powder Thickness

- Elcometer 3230 Coil Coating Wet Film Wheels

Elcometer 3230 Coil Coating Wet Film Wheels

- Protective Coatings

These Elcometer 3230 Coil Coating Wet Film Wheels are high precision, accurate and easy to use instruments that are designed for use in the coil coating process.

Summary

Elcometer 3230 Coil Coating Wet Film Wheels

The outer wheels are knurled to allow measurements to be taken on slippery coatings or on fast moving substrates.

By rolling the gauge through a wet coating, the centre wheel eventually touches the film. This point on the scale indicates the thickness.

When the volume to solids ratio of the coating is known (generally found on the product data sheet supplied by the manufacturer), the wet film thickness can be used to predict the dry film thickness.

Technical SpecificationElcometer 3230 Coil Coating Wet Film WheelsPart Number Range Graduations Certificate Metric Film Wheels K0003230M017 0 - 50μm 2.5μm

K0003230M018 0 - 100μm 5.0μm

Imperial Film Wheels K0US3230M017 0 - 2mils 0.1mils

K0US3230M018 0 - 4mils 0.2mils

Dimensions 50 x 30mm (1.97 x 1.18”) Weight 220g (7.76oz) Packing List Coil Coating Wet Film Wheel, storage case and operating instructions Part Number Dimensions Certificate Metric Film Wheels K0003230M017 0 - 50μm

Weight 2.5μm K0003230M018 0 - 100μm

Weight 5.0μm Imperial Film Wheels K0US3230M017 0 - 2mils

Weight 0.1mils K0US3230M018 0 - 4mils

Weight 0.2mils Dimensions 50 x 30mm (1.97 x 1.18”) Weight 220g (7.76oz) Packing List Coil Coating Wet Film Wheel, storage case and operating instructions ○ Optional Calibration Certificate available.StandardsElcometer 3230 Coil Coating Wet Film WheelsASTM D 1212-A, AS/NZS 1580.107.3, BS 3900-C5-7A, ISO 2808-1B, ISO 2808-7A, JIS K 5600-1-7, NF T30-125

Standards in grey have been superseded but are still recognised in some industries.

Part NumbersElcometer 3230 Coil Coating Wet Film WheelsNo data found!!-

Elcometer 3230 Coil Coating Wet Film Wheel

Elcometer 3230 Coil Coating Wet Film Wheel- Range: 0 - 50μm

- Part Number : K0003230M017

-

Elcometer 3230 Coil Coating Wet Film Wheel

Elcometer 3230 Coil Coating Wet Film Wheel- Range: 0 - 100μm

- Part Number : K0003230M018

-

Elcometer 3230 Coil Coating Wet Film Wheel

Elcometer 3230 Coil Coating Wet Film Wheel- Range: 0 - 2mils

- Part Number : K0US3230M017

-

Elcometer 3230 Coil Coating Wet Film Wheel

Elcometer 3230 Coil Coating Wet Film Wheel- Range: 0 - 4mils

- Part Number : K0US3230M018

Welcome to Elcometer.tv

Your ultimate training channelAccessoriesElcometer 3230 Coil Coating Wet Film Wheels Part Number: KT003230N003

Part Number: KT003230N003 Part Number: KT003230N002

Part Number: KT003230N002

- Part Numbers

-