Elcometer 213/2 Digital Waterproof Thermometer

- Protective Coatings

- Industrial Finishing

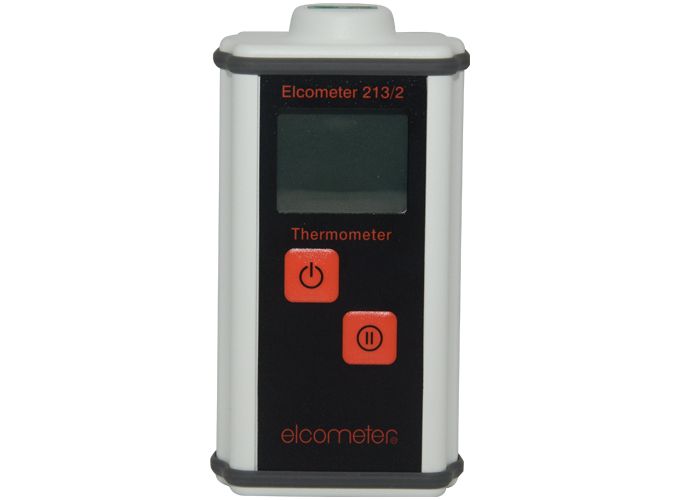

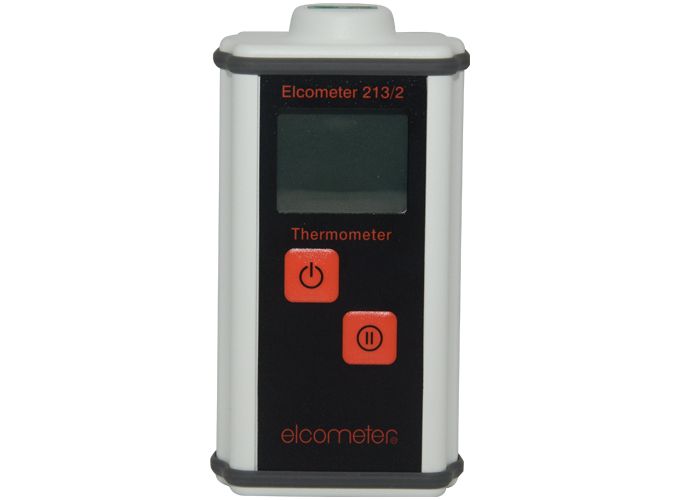

The Elcometer 213/2 Digital Waterproof Thermometer is simple and easy-to-use for quick and easy measurements of the surface, air and liquid temperature as well as the temperature of soft materials.

- Summary

-

Summary

-

The Elcometer 213/2 Digital Waterproof Thermometer offers the latest microprocessor technology, superior durability and is designed for reliability and ease of use.

Features:

- Rubber bumper seals for impact resistance

- Waterproof case (IP66 & IP67 protection)

- Extruded aluminium case for superior durability

- °C/°F switchable

- Easy to read LCD display

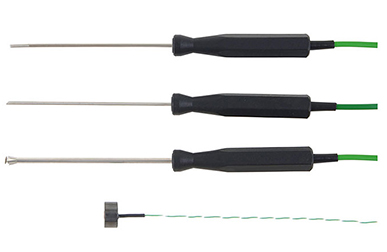

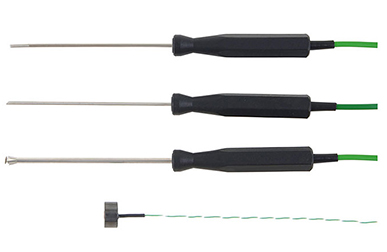

Probes are available to purchase separately.

-

- Technical Information

-

Technical SpecificationElcometer 213/2 Digital Waterproof Thermometer

Part Number Description Certificate G213----2 Elcometer 213/2 Digital Waterproof Thermometer1

Operating Range -49°C to +1372°C (-56°F to 2500°F) 2 Accuracy ±1% of the reading ±1 digit Resolution 0.1°C (0.1°F) up to 299.9°C (572°F), 1°C (1°F) above 299.9°C (599.9°F) Battery Life 5,000 hours Power Supply 3 x AAA (LR03) 1.5V Dimensions 35 x 60 x 115mm (1.4 x 2.4 x 4.5”) Weight 194g (0.42lb) Packing List Elcometer 213/2 Digital Waterproof Thermometer, battery, carry case and operating instructions 1 Probes are not supplied as standard with the Elcometer 213/2; please select from accessories

2 Operating range is dependent on probe used

○ Optional Calibration Certificate available.

-

- Downloads

-

Downloads

- Part Numbers

-

Part NumbersElcometer 213/2 Digital Waterproof ThermometerNo data found!!

-

Elcometer 213/2 Digital Waterproof Thermometer

Elcometer 213/2 Digital Waterproof Thermometer- Part Number : G213----2

-

Elcometer 213/2 Digital Waterproof Thermometer

Elcometer 213/2 Digital Waterproof Thermometer- Part Number : G213----2C

- Accessories

-

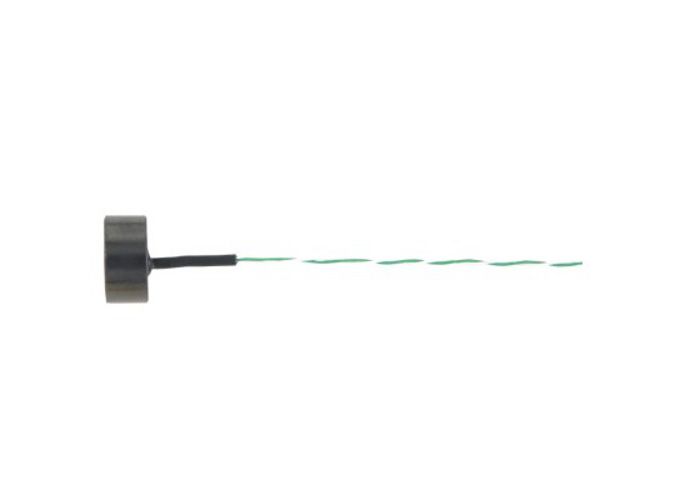

AccessoriesElcometer 213/2 Digital Waterproof Thermometer

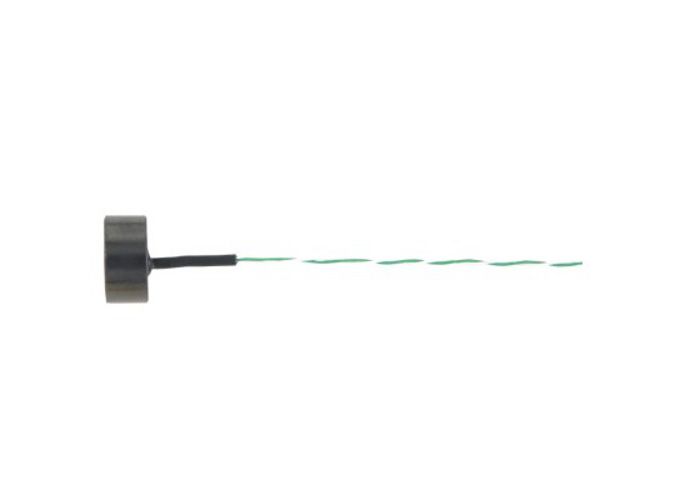

Part Number: T9996390-

Part Number: T9996390- Part Number: T99911728

Part Number: T99911728 Part Number: T2136069-

Part Number: T2136069- Part Number: T2136391

Part Number: T2136391

Welcome to Elcometer.tv

Your ultimate training channel -

- Home

- Coatings Inspection

- Coatings Inspection Division

- Climate, Dewpoint & Relative Humidity

- Elcometer 213/2 Digital Waterproof Thermometer

Elcometer 213/2 Digital Waterproof Thermometer

- Protective Coatings

- Industrial Finishing

The Elcometer 213/2 Digital Waterproof Thermometer is simple and easy-to-use for quick and easy measurements of the surface, air and liquid temperature as well as the temperature of soft materials.

Summary

Elcometer 213/2 Digital Waterproof Thermometer

The Elcometer 213/2 Digital Waterproof Thermometer offers the latest microprocessor technology, superior durability and is designed for reliability and ease of use.

Features:

- Rubber bumper seals for impact resistance

- Waterproof case (IP66 & IP67 protection)

- Extruded aluminium case for superior durability

- °C/°F switchable

- Easy to read LCD display

Probes are available to purchase separately.

Technical SpecificationElcometer 213/2 Digital Waterproof ThermometerPart Number Description Certificate G213----2 Elcometer 213/2 Digital Waterproof Thermometer1

Operating Range -49°C to +1372°C (-56°F to 2500°F) 2 Accuracy ±1% of the reading ±1 digit Resolution 0.1°C (0.1°F) up to 299.9°C (572°F), 1°C (1°F) above 299.9°C (599.9°F) Battery Life 5,000 hours Power Supply 3 x AAA (LR03) 1.5V Dimensions 35 x 60 x 115mm (1.4 x 2.4 x 4.5”) Weight 194g (0.42lb) Packing List Elcometer 213/2 Digital Waterproof Thermometer, battery, carry case and operating instructions 1 Probes are not supplied as standard with the Elcometer 213/2; please select from accessories

2 Operating range is dependent on probe used

○ Optional Calibration Certificate available.Part NumbersElcometer 213/2 Digital Waterproof ThermometerNo data found!!-

Elcometer 213/2 Digital Waterproof Thermometer

Elcometer 213/2 Digital Waterproof Thermometer- Part Number : G213----2

-

Elcometer 213/2 Digital Waterproof Thermometer

Elcometer 213/2 Digital Waterproof Thermometer- Part Number : G213----2C

Welcome to Elcometer.tv

Your ultimate training channelAccessoriesElcometer 213/2 Digital Waterproof Thermometer Part Number: T9996390-

Part Number: T9996390- Part Number: T99911728

Part Number: T99911728 Part Number: T2136069-

Part Number: T2136069- Part Number: T2136391

Part Number: T2136391

- Part Numbers

-