Elcometer 319 Dewpoint Meter

- Protective Coatings

- Industrial Finishing

The rugged Elcometer 319 Dew Point Meter is designed to measure and record all relevant climatic parameters required to determine whether the conditions are suitable for painting.

- Summary

-

Summary

-

Accurate

- The Elcometer 319 Dewpoint Meter meets International Standards including ISO 8502-4

- Supplied with a Calibration Certificate

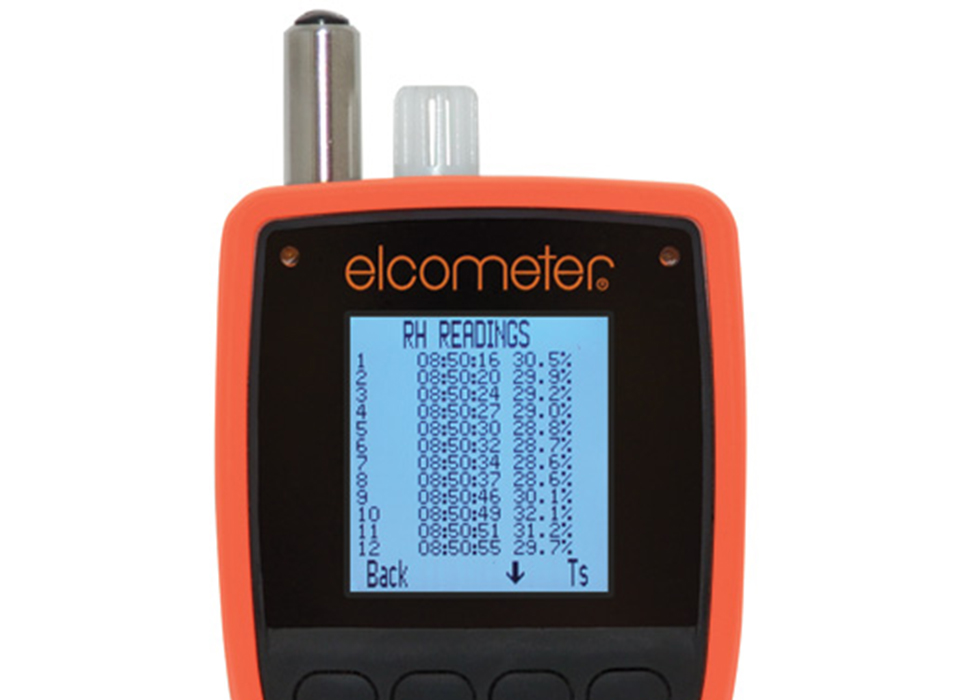

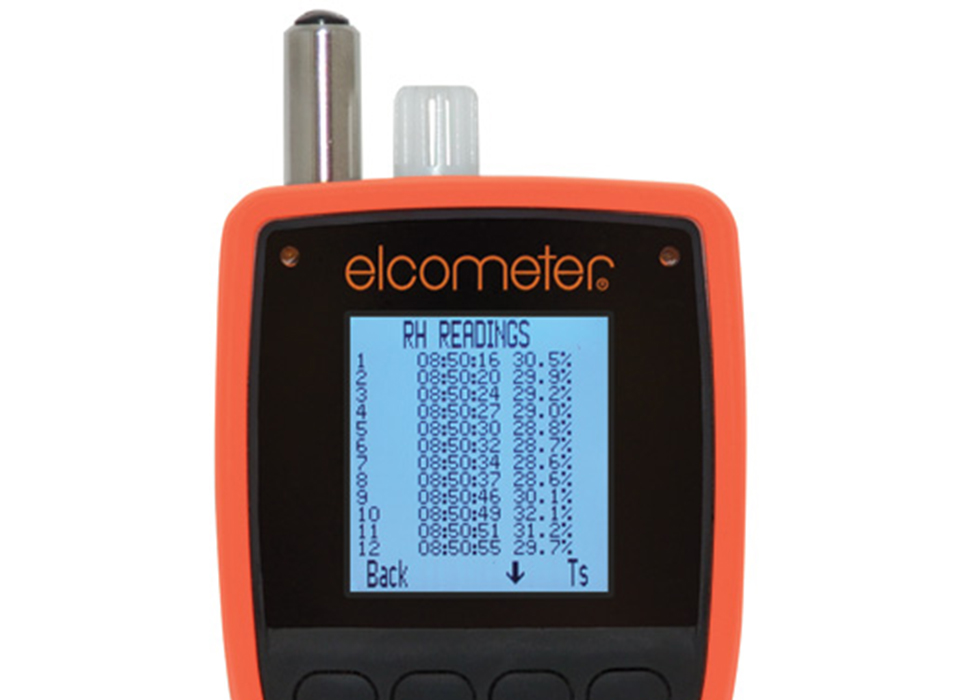

- All readings are time & date stamped

Simple

- The Elcometer 319 Dew Point Meter has an easy to use menu-driven user interface in multiple languages

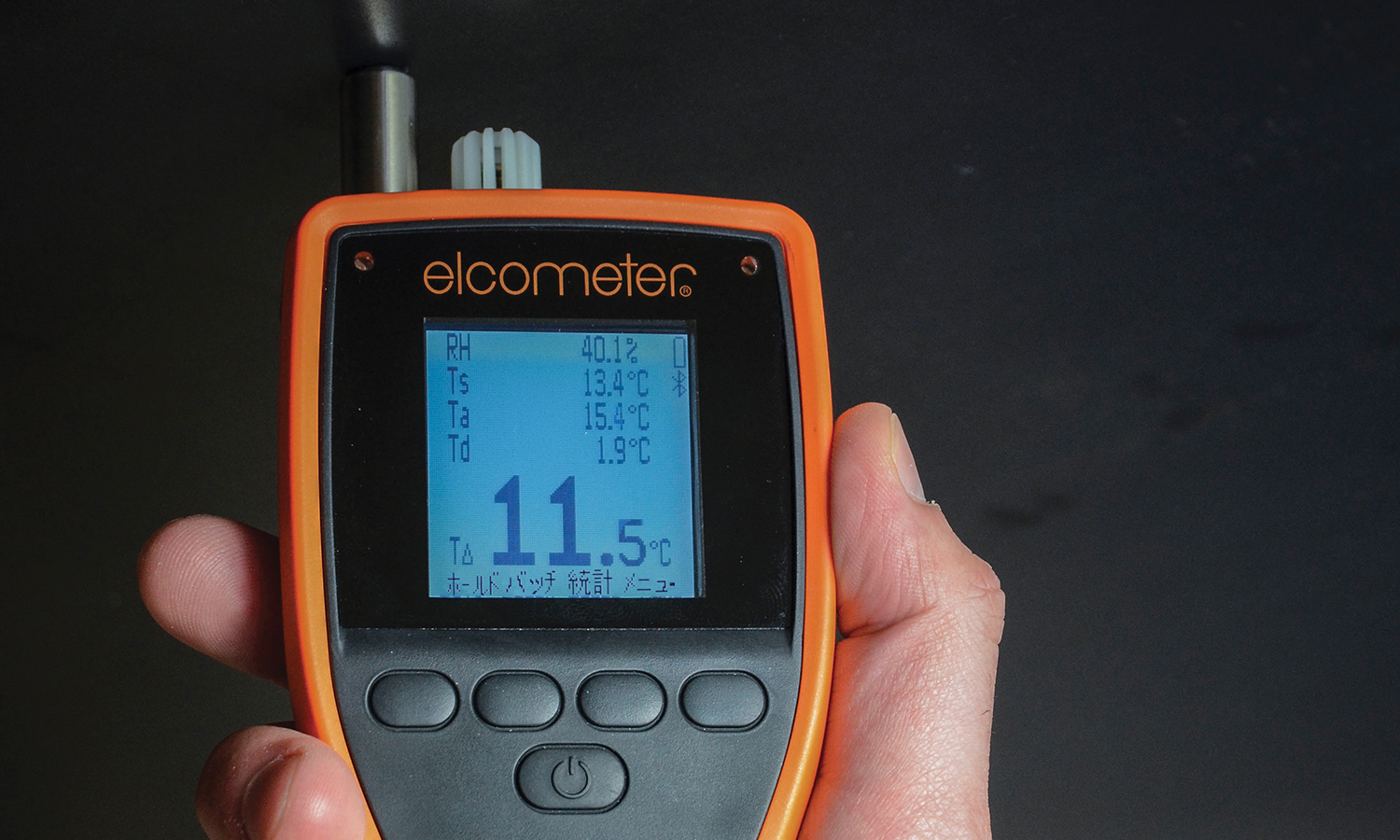

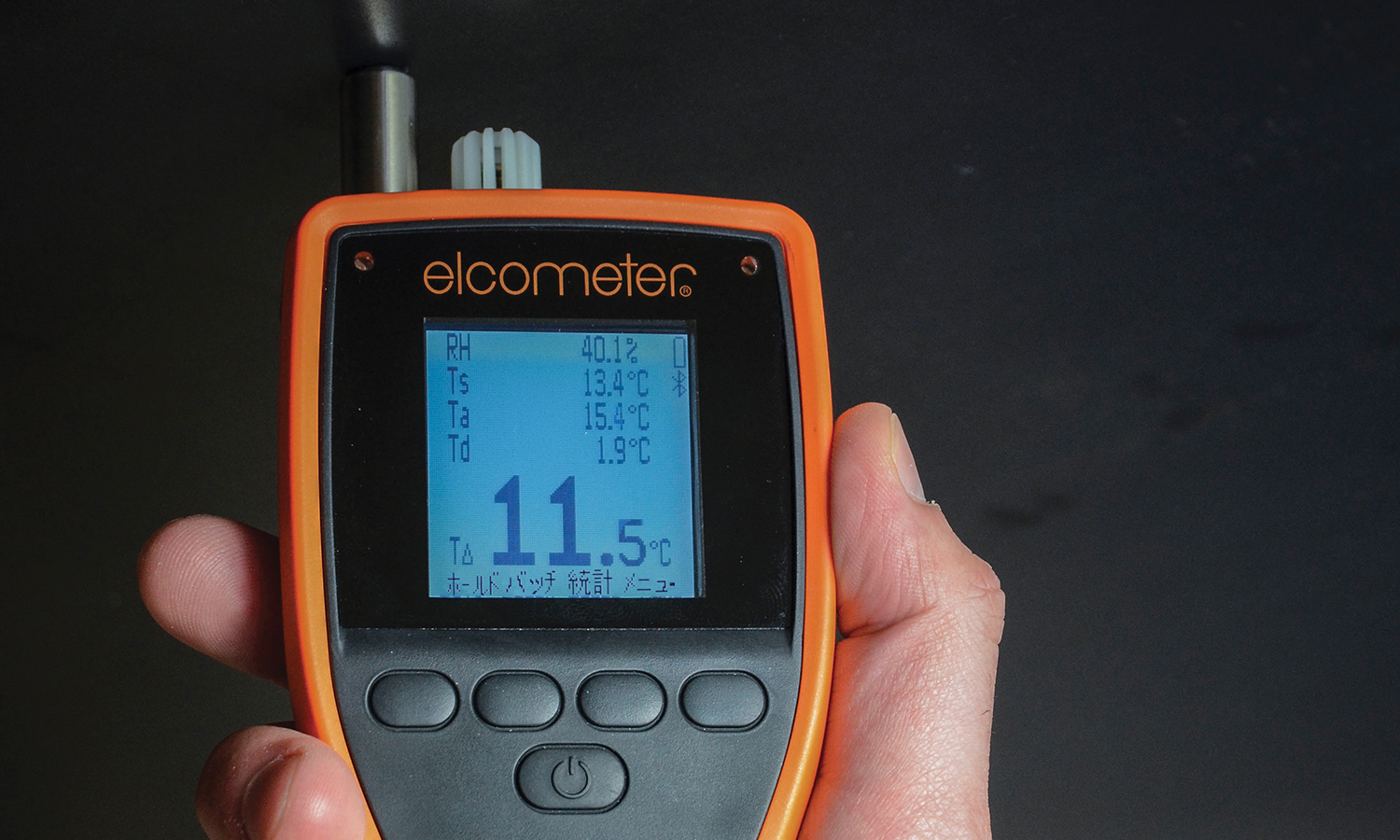

- Clear, illuminated display showing up to five user-defined parameters

- Arrow indicators show temperature trends

- Hold/freeze function allows manual readings to be reviewed before being added into the memory

Flexible

- The Elcometer 319 Dewpoint Meter - Model T can be used as a hand-held dewpoint meter or as a remote data logging monitor

- Magnetic Surface Temperature Probe allows measurement of surface temperature during remote logging

- Liquid temperature probe transforms the gauge into a thermometer

The versatile Elcometer 319 Dew Point Meter is able to measure and record the following climatic parameters:

• Relative humidity

• Air temperature

• Surface temperature

• Dewpoint temperature

• TΔ (the difference between surface temperature and dewpoint)

• Dry Bulb temperature

• Wet Bulb temperature

• External temperature correction (K-type)

• Specific humidityElcoMaster® Data Management Software

Inspectors can spend up to 30% of their working week producing reports. ElcoMaster® Software saves time and money by producing professional bespoke reports - even when out on site.

-

- Key Features

-

Key Features

Elcometer 319 Dewpoint Meter

Durable

- The Elcometer 319 Dewpoint Meter is safe to use in climates ranging between -20°C (-4°F) and +80°C (+176°F)

- Water-resistant and dustproof with fully sealed sensors - rating equivalent to IP66

- Re-engineered sensors have greater durability for an extended life

Powerful

- Data can be downloaded from the Elcometer 319 Dew Point Meter to a PC via USB or Bluetooth® and evaluated using ElcoMaster® Software1

- Powered by either two AA batteries (for up to 400 hours2 use) or directly via the USB cable

- Intelligent memory calculates total available logging time when using batches

- Stores 25,000 records in up to 999 batches1

Quick, Simple and Easy-to-Use Dewpoint Meter

The Elcometer 319 Dew Point Meter features both manual and automatic data logging in one gauge1, with integrated magnets allowing the gauge to be attached to a substrate during remote logging. Its rapid response time and intuitive menu structure make measuring climatic conditions quick and easy.

Adjustable limits can be set for each measurement parameter which triggers visual and audible alarms whenever a limit is exceeded, ideal for use in paint booths.

Flexible and Versatile

Using external probes, the versatile gauge can also be used as a thermometer - ideal for measuring temperature of paint prior to application and to measure surface temperature during remote logging.

It's what you do with the data that counts

Via Bluetooth® or USB, the Elcometer 319 Dewpoint Meter can be connected to a PC, Android™ or iOS mobile device to download data into an inspection application or ElcoMaster®. Data can then be sent to colleagues and clients in real-time and instant professional inspection reports can be generated at the press of a button.

Large easy to read measurements in degrees °C or °F

View up to five user selectable statistics on screen

Review individual readings

1 Model T only

2 Based on one reading every 10 minutes in logging mode.Elcometer 319 Model T: Made for iPhone 6 Plus, iPhone 6, iPhone 5s, iPhone 5c, iPhone 5, iPhone 4s, iPhone 4, iPad Air 2, iPad mini 3, iPad Air, iPad mini 2, iPad (3rd and 4th generation), iPad mini, iPad 2, and iPod touch (4th and 5th generation).

“Made for iPod,” “Made for iPhone,” and “Made for iPad” mean that an electronic accessory has been designed to connect specifically to iPod, iPhone, or iPad, respectively, and has been certified by the developer to meet Apple performance standards. Apple is not responsible for the operation of this device or its compliance with safety and regulatory standards. Please note that the use of this accessory with iPod, iPhone, or iPad may affect wireless performance.

iPad, iPhone, and iPod touch are trademarks of Apple Inc., registered in the U.S. and other countries. App Store is a trademark of Apple Inc., registered in the U.S. and other countries. Suitable for mobile devices running Android™ software version 2.1 and upwards. Android™ and Google Play are trademarks of Google Inc.

-

- Technical Information

-

Technical SpecificationElcometer 319 Dewpoint Meter

Model Model S Model T Certificate Part Number G319----S G319----T

Reading Parameters - RH, Ta, Ts (Te6), Td, TΔ, Tdb, Twb1, SH1 Statistics - number of readings, standard deviation, mean, coefficient of variation, minimum, maximum Dustproof & waterproof with fully sealed sensors - equivalent to IP66 Integral Magnets - secure the gauge during logging High/Low Limits - audible, visual, red/green LED alarms can be set against any or all parameters Multilingual Menus Backlight - user selectable K-Type Connector for external probes Memory - with reading and statistic review Last 10 records 25,000 records in 999 batches Manual Logging Interval Logging2 Adjustable between 1 second and 24 hours *Data Output* USB Bluetooth® to computer, Android™ & iOS4 devices ElcoMaster® software & USB cable Temperature Range Accuracy Resolution Gauge5 -20 to +80°C (-4 to +176°F) ±0.5°C (±1°F) 0.1°C (0.1°F) Air Temperature (Ta) -20 to +80°C (-4 to +176°F) ±0.5°C (±1°F)7 0.1°C (0.1°F) Surface Temperature (TS) -20 to +80°C (-4 to +176°F) ±0.5°C (±1°F) 0.1°C (0.1°F) External K-Type Thermocouple (Te) -40 to +200°C (-40 to+392°F) ±0.5°C (±1°F)6 0.1°C (0.1°F) Relative Humidity (RH) 0 to 100%RH ±3%RH3 0.1% Gauge & LCD Operating Range -20°C to +80°C (-4°F to +176°F) Power Supply 2 x AA batteries or via USB Cable Battery Life Manual Mode: Greater than 40 hours (Backlight Off)

Interval Logging: up to 400 hours (1 reading every 10 minutes)Dimensions 180 x 75 x 35mm (7 x 3 x 1.4”) Weight 300g (0.66lb) Packing List Elcometer 319 Dewpoint Meter, 2 x AA batteries, wrist strap, carry case, calibration certificate, USB cable8, ElcoMaster®8 and operating instructions Model Model S Model T Part Number G319----S G319----T Certificate

Reading Parameters - RH, Ta, Ts (Te6), Td, TΔ, Tdb, Twb1, SH1 Statistics - number of readings, standard deviation, mean, coefficient of variation, minimum, maximum Dustproof & waterproof with fully sealed sensors - equivalent to IP66 Integral Magnets - secure the gauge during logging High/Low Limits - audible, visual, red/green LED alarms can be set against any or all parameters Multilingual Menus Backlight - user selectable K-Type Connector for external probes Memory - with reading and statistic review Last 10 records 25,000 records in 999 batches Manual Logging Interval Logging2 Adjustable between 1 second and 24 hours USB Bluetooth® to computer, Android™ & iOS4 devices ElcoMaster® software & USB cable Gauge5 Temperature Range Accuracy Resolution -20 to +80°C (-4 to +176°F) ±0.5°C (±1°F) 0.1°C (0.1°F) Air Temperature (Ta) Temperature Range Accuracy Resolution -20 to +80°C (-4 to +176°F) ±0.5°C (±1°F)7 0.1°C (0.1°F) Surface Temperature (TS) Temperature Range Accuracy Resolution -20 to +80°C (-4 to +176°F) ±0.5°C (±1°F) 0.1°C (0.1°F) External K-Type Thermocouple (Te) Temperature Range Accuracy Resolution -40 to +200°C (-40 to+392°F) ±0.5°C (±1°F)6 0.1°C (0.1°F) Relative Humidity (RH) Temperature Range Accuracy Resolution 0 to 100%RH ±3%RH3 0.1% Gauge & LCD Operating Range -20°C to +80°C (-4°F to +176°F) Power Supply 2 x AA batteries or via USB Cable Battery Life Manual Mode: Greater than 40 hours (Backlight Off)

Interval Logging: up to 400 hours (1 reading every 10 minutes)Dimensions 180 x 75 x 35mm (7 x 3 x 1.4”) Weight 300g (0.66lb) Packing List Elcometer 319 Dewpoint Meter, 2 x AA batteries, wrist strap, carry case, calibration certificate, USB cable8, ElcoMaster®8 and operating instructions 1 Calculated Value

2 With Part Number T31920162

3at 1m/s

4Visit www.elcometer.com/sdk to find out how to integrate Elcometer’s MFi certified products to your App.

5 Do not expose the gauge to temperatures outside the gauge and LCD operating range

6Accuracy ±2°C (4°F) with K Type probes supplied by Elcometer. Gauge tested with voltage input

7 Accuracy ±0.75°C below 10°C (±1.35°F below 50°F)

8 Model T only.

●Certificate supplied as standard.

-

- Standards

-

StandardsElcometer 319 Dewpoint Meter

BS 7079-B4, IMO MSC.215(82), IMO MSC.244(83), ISO 8502-4, US Navy NSI 009-32, US Navy PPI 63101-000

Standards in grey have been superseded but are still recognised in some industries.

-

- Downloads

-

Downloads

-

Elcometer 319 Dewpoint Meter - Instruction Manual

-

Elcometer 319 Dewpoint Meter - Datasheet

-

Elcometer 319 Dewpoint Meter Model S CE Declaration of Conformity

-

Elcometer 319 Model S Dewpoint Meter UKCA Declaration of Conformity

-

Elcometer 319 Dewpoint Meter Model T CE Declaration of Conformity

-

Elcometer 319 Model T Dewpoint Meter UKCA Declaration of Conformity

- Part Numbers

-

Part NumbersElcometer 319 Dewpoint MeterNo data found!!

-

Elcometer 319 Dewpoint Meter (Model S)

Elcometer 319 Dewpoint Meter (Model S)- Model: Model S

- Memory - with reading and statistic review: Last 10 records

- Part Number : G319----S

-

Elcometer 319 Dewpoint Meter (Model T)

Elcometer 319 Dewpoint Meter (Model T)- Model: Model T

- Memory - with reading and statistic review: 25,000 records in 999 batches

- Part Number : G319----T

- Accessories

-

AccessoriesElcometer 319 Dewpoint Meter

Part Number: T31920162

Part Number: T31920162 Part Number: T9996390-

Part Number: T9996390- Part Number: T99921325

Part Number: T99921325 Part Number: T99916063

Part Number: T99916063 Part Number: T99923480

Part Number: T99923480

Welcome to Elcometer.tv

Your ultimate training channel

- Home

- Coatings Inspection

- Coatings Inspection Division

- Climate, Dewpoint & Relative Humidity

- Elcometer 319 Dewpoint Meter

Elcometer 319 Dewpoint Meter

- Protective Coatings

- Industrial Finishing

The rugged Elcometer 319 Dew Point Meter is designed to measure and record all relevant climatic parameters required to determine whether the conditions are suitable for painting.

Accurate

- The Elcometer 319 Dewpoint Meter meets International Standards including ISO 8502-4

- Supplied with a Calibration Certificate

- All readings are time & date stamped

Simple

- The Elcometer 319 Dew Point Meter has an easy to use menu-driven user interface in multiple languages

- Clear, illuminated display showing up to five user-defined parameters

- Arrow indicators show temperature trends

- Hold/freeze function allows manual readings to be reviewed before being added into the memory

Flexible

- The Elcometer 319 Dewpoint Meter - Model T can be used as a hand-held dewpoint meter or as a remote data logging monitor

- Magnetic Surface Temperature Probe allows measurement of surface temperature during remote logging

- Liquid temperature probe transforms the gauge into a thermometer

Summary

Elcometer 319 Dewpoint Meter

The versatile Elcometer 319 Dew Point Meter is able to measure and record the following climatic parameters:

• Relative humidity

• Air temperature

• Surface temperature

• Dewpoint temperature

• TΔ (the difference between surface temperature and dewpoint)

• Dry Bulb temperature

• Wet Bulb temperature

• External temperature correction (K-type)

• Specific humidityElcoMaster® Data Management Software

Inspectors can spend up to 30% of their working week producing reports. ElcoMaster® Software saves time and money by producing professional bespoke reports - even when out on site.

Downloads-

Elcometer 319 Dewpoint Meter - Instruction Manual

-

Elcometer 319 Dewpoint Meter - Datasheet

-

Elcometer 319 Dewpoint Meter Model S CE Declaration of Conformity

-

Elcometer 319 Model S Dewpoint Meter UKCA Declaration of Conformity

-

Elcometer 319 Dewpoint Meter Model T CE Declaration of Conformity

-

Elcometer 319 Model T Dewpoint Meter UKCA Declaration of Conformity

Key Features

Elcometer 319 Dewpoint Meter

Durable

- The Elcometer 319 Dewpoint Meter is safe to use in climates ranging between -20°C (-4°F) and +80°C (+176°F)

- Water-resistant and dustproof with fully sealed sensors - rating equivalent to IP66

- Re-engineered sensors have greater durability for an extended life

Powerful

- Data can be downloaded from the Elcometer 319 Dew Point Meter to a PC via USB or Bluetooth® and evaluated using ElcoMaster® Software1

- Powered by either two AA batteries (for up to 400 hours2 use) or directly via the USB cable

- Intelligent memory calculates total available logging time when using batches

- Stores 25,000 records in up to 999 batches1

Quick, Simple and Easy-to-Use Dewpoint Meter

The Elcometer 319 Dew Point Meter features both manual and automatic data logging in one gauge1, with integrated magnets allowing the gauge to be attached to a substrate during remote logging. Its rapid response time and intuitive menu structure make measuring climatic conditions quick and easy.

Adjustable limits can be set for each measurement parameter which triggers visual and audible alarms whenever a limit is exceeded, ideal for use in paint booths.

Flexible and Versatile

Using external probes, the versatile gauge can also be used as a thermometer - ideal for measuring temperature of paint prior to application and to measure surface temperature during remote logging.

It's what you do with the data that counts

Via Bluetooth® or USB, the Elcometer 319 Dewpoint Meter can be connected to a PC, Android™ or iOS mobile device to download data into an inspection application or ElcoMaster®. Data can then be sent to colleagues and clients in real-time and instant professional inspection reports can be generated at the press of a button.

Large easy to read measurements in degrees °C or °F

View up to five user selectable statistics on screen

Review individual readings

1 Model T only

2 Based on one reading every 10 minutes in logging mode.Elcometer 319 Model T: Made for iPhone 6 Plus, iPhone 6, iPhone 5s, iPhone 5c, iPhone 5, iPhone 4s, iPhone 4, iPad Air 2, iPad mini 3, iPad Air, iPad mini 2, iPad (3rd and 4th generation), iPad mini, iPad 2, and iPod touch (4th and 5th generation).

“Made for iPod,” “Made for iPhone,” and “Made for iPad” mean that an electronic accessory has been designed to connect specifically to iPod, iPhone, or iPad, respectively, and has been certified by the developer to meet Apple performance standards. Apple is not responsible for the operation of this device or its compliance with safety and regulatory standards. Please note that the use of this accessory with iPod, iPhone, or iPad may affect wireless performance.

iPad, iPhone, and iPod touch are trademarks of Apple Inc., registered in the U.S. and other countries. App Store is a trademark of Apple Inc., registered in the U.S. and other countries. Suitable for mobile devices running Android™ software version 2.1 and upwards. Android™ and Google Play are trademarks of Google Inc.

Technical SpecificationElcometer 319 Dewpoint MeterModel Model S Model T Certificate Part Number G319----S G319----T

Reading Parameters - RH, Ta, Ts (Te6), Td, TΔ, Tdb, Twb1, SH1 Statistics - number of readings, standard deviation, mean, coefficient of variation, minimum, maximum Dustproof & waterproof with fully sealed sensors - equivalent to IP66 Integral Magnets - secure the gauge during logging High/Low Limits - audible, visual, red/green LED alarms can be set against any or all parameters Multilingual Menus Backlight - user selectable K-Type Connector for external probes Memory - with reading and statistic review Last 10 records 25,000 records in 999 batches Manual Logging Interval Logging2 Adjustable between 1 second and 24 hours *Data Output* USB Bluetooth® to computer, Android™ & iOS4 devices ElcoMaster® software & USB cable Temperature Range Accuracy Resolution Gauge5 -20 to +80°C (-4 to +176°F) ±0.5°C (±1°F) 0.1°C (0.1°F) Air Temperature (Ta) -20 to +80°C (-4 to +176°F) ±0.5°C (±1°F)7 0.1°C (0.1°F) Surface Temperature (TS) -20 to +80°C (-4 to +176°F) ±0.5°C (±1°F) 0.1°C (0.1°F) External K-Type Thermocouple (Te) -40 to +200°C (-40 to+392°F) ±0.5°C (±1°F)6 0.1°C (0.1°F) Relative Humidity (RH) 0 to 100%RH ±3%RH3 0.1% Gauge & LCD Operating Range -20°C to +80°C (-4°F to +176°F) Power Supply 2 x AA batteries or via USB Cable Battery Life Manual Mode: Greater than 40 hours (Backlight Off)

Interval Logging: up to 400 hours (1 reading every 10 minutes)Dimensions 180 x 75 x 35mm (7 x 3 x 1.4”) Weight 300g (0.66lb) Packing List Elcometer 319 Dewpoint Meter, 2 x AA batteries, wrist strap, carry case, calibration certificate, USB cable8, ElcoMaster®8 and operating instructions Model Model S Model T Part Number G319----S G319----T Certificate

Reading Parameters - RH, Ta, Ts (Te6), Td, TΔ, Tdb, Twb1, SH1 Statistics - number of readings, standard deviation, mean, coefficient of variation, minimum, maximum Dustproof & waterproof with fully sealed sensors - equivalent to IP66 Integral Magnets - secure the gauge during logging High/Low Limits - audible, visual, red/green LED alarms can be set against any or all parameters Multilingual Menus Backlight - user selectable K-Type Connector for external probes Memory - with reading and statistic review Last 10 records 25,000 records in 999 batches Manual Logging Interval Logging2 Adjustable between 1 second and 24 hours USB Bluetooth® to computer, Android™ & iOS4 devices ElcoMaster® software & USB cable Gauge5 Temperature Range Accuracy Resolution -20 to +80°C (-4 to +176°F) ±0.5°C (±1°F) 0.1°C (0.1°F) Air Temperature (Ta) Temperature Range Accuracy Resolution -20 to +80°C (-4 to +176°F) ±0.5°C (±1°F)7 0.1°C (0.1°F) Surface Temperature (TS) Temperature Range Accuracy Resolution -20 to +80°C (-4 to +176°F) ±0.5°C (±1°F) 0.1°C (0.1°F) External K-Type Thermocouple (Te) Temperature Range Accuracy Resolution -40 to +200°C (-40 to+392°F) ±0.5°C (±1°F)6 0.1°C (0.1°F) Relative Humidity (RH) Temperature Range Accuracy Resolution 0 to 100%RH ±3%RH3 0.1% Gauge & LCD Operating Range -20°C to +80°C (-4°F to +176°F) Power Supply 2 x AA batteries or via USB Cable Battery Life Manual Mode: Greater than 40 hours (Backlight Off)

Interval Logging: up to 400 hours (1 reading every 10 minutes)Dimensions 180 x 75 x 35mm (7 x 3 x 1.4”) Weight 300g (0.66lb) Packing List Elcometer 319 Dewpoint Meter, 2 x AA batteries, wrist strap, carry case, calibration certificate, USB cable8, ElcoMaster®8 and operating instructions 1 Calculated Value

2 With Part Number T31920162

3at 1m/s

4Visit www.elcometer.com/sdk to find out how to integrate Elcometer’s MFi certified products to your App.

5 Do not expose the gauge to temperatures outside the gauge and LCD operating range

6Accuracy ±2°C (4°F) with K Type probes supplied by Elcometer. Gauge tested with voltage input

7 Accuracy ±0.75°C below 10°C (±1.35°F below 50°F)

8 Model T only.

●Certificate supplied as standard.StandardsElcometer 319 Dewpoint MeterBS 7079-B4, IMO MSC.215(82), IMO MSC.244(83), ISO 8502-4, US Navy NSI 009-32, US Navy PPI 63101-000

Standards in grey have been superseded but are still recognised in some industries.

Part NumbersElcometer 319 Dewpoint MeterNo data found!!-

Elcometer 319 Dewpoint Meter (Model S)

Elcometer 319 Dewpoint Meter (Model S)- Model: Model S

- Memory - with reading and statistic review: Last 10 records

- Part Number : G319----S

-

Elcometer 319 Dewpoint Meter (Model T)

Elcometer 319 Dewpoint Meter (Model T)- Model: Model T

- Memory - with reading and statistic review: 25,000 records in 999 batches

- Part Number : G319----T

Welcome to Elcometer.tv

Your ultimate training channelAccessoriesElcometer 319 Dewpoint Meter Part Number: T31920162

Part Number: T31920162 Part Number: T9996390-

Part Number: T9996390- Part Number: T99921325

Part Number: T99921325 Part Number: T99916063

Part Number: T99916063 Part Number: T99923480

Part Number: T99923480

-

-