Elcometer 500 Coating Thickness Gauge - Cementitious Substrates

- Protective Coatings

The Elcometer 500 Coating Thickness Gauge accurately measures the thickness of coatings on concrete and other similar substrates* - non destructively.

- Summary

-

Summary

-

Fast

Measuring over 60 readings per minute in standard mode and over 140 readings per minute in scan mode, the Elcometer 500 Coating Thickness Gauge can significantly reduce your inspection times.

Intelligent

The Elcometer 500 Coatings on Concrete Gauge measurement probes are supplied with user replaceable probe tips. If the tip is damaged or wears during use you can replace it and carry on.

The gauge even informs you when you need to change the probe tip, maximising inspection time.

Reliable

The Elcometer 500 Coating Thickness Gauge will only display the coating thickness reading if the signal strength indicator turns green, preventing false or incorrect readings.

If the coating thickness is outside the measurement range, the Elcometer 500 Concrete Coating Thickness Gauge tells you on the display.

Fast and accurate, the Elcometer 500 Coating Thickness Gauge takes repeatable and reproducible dry film thickness measurements of coatings on concrete up to 10mm‡ thick – without damaging the coating.

Taking over 60 readings per minute in standard mode and 140+ readings per minute in scan mode; the Elcometer 500 Coating Thickness Gauge allows users to inspect more coatings in less time. With a choice of intelligent, ergonomic probes, designed for continuous use and field replaceable probe tips you can inspect all day, everyday.

The built in signal strength indicator on the Elcometer 500 Coatings on Concrete Gauge prevents false or incorrect readings, as the gauge only displays the coating thickness measurement if the signal strength indicator goes green.

Robust, ergonomic and sealed against dirt and water, equivalent to a rating of IP54, the Elcometer 500 Concrete Coating Thickness Gauge has been designed to work in harsh environments.

Incredibly easy to use, the Elcometer 500 Coating Thickness Gauge for concrete can be used in accordance with ASTM D6132, SSPC PA9 & ISO 2808 Method 10.

Compatible with ElcoMaster® software and ElcoMaster® Mobile App, individual coating thickness measurements can be transferred via USB or Bluetooth® to PC or a mobile device for analysis and instant report generation.

-

- Key Features

-

Key Features

Elcometer 500 Coating Thickness Gauge - Cementitious Substrates

Easy to Use

There is no need to set up gates, range values or know the thickness of the coating, simply select the coating material from the gauge library and start measuring.

Ergonomic

The Elcometer 500 Coatings on Concrete Thickness Gauge and intelligent probes have all been ergonomically designed for continuous use. No force is required to take a reading.

Rugged

Robust, ergonomic and sealed against dirt and water, equivalent to a rating of IP54, the Elcometer 500 Coating Thickness Gauge has been designed to work in harsh environments, making it the ideal gauge for the laboratory or the job site.

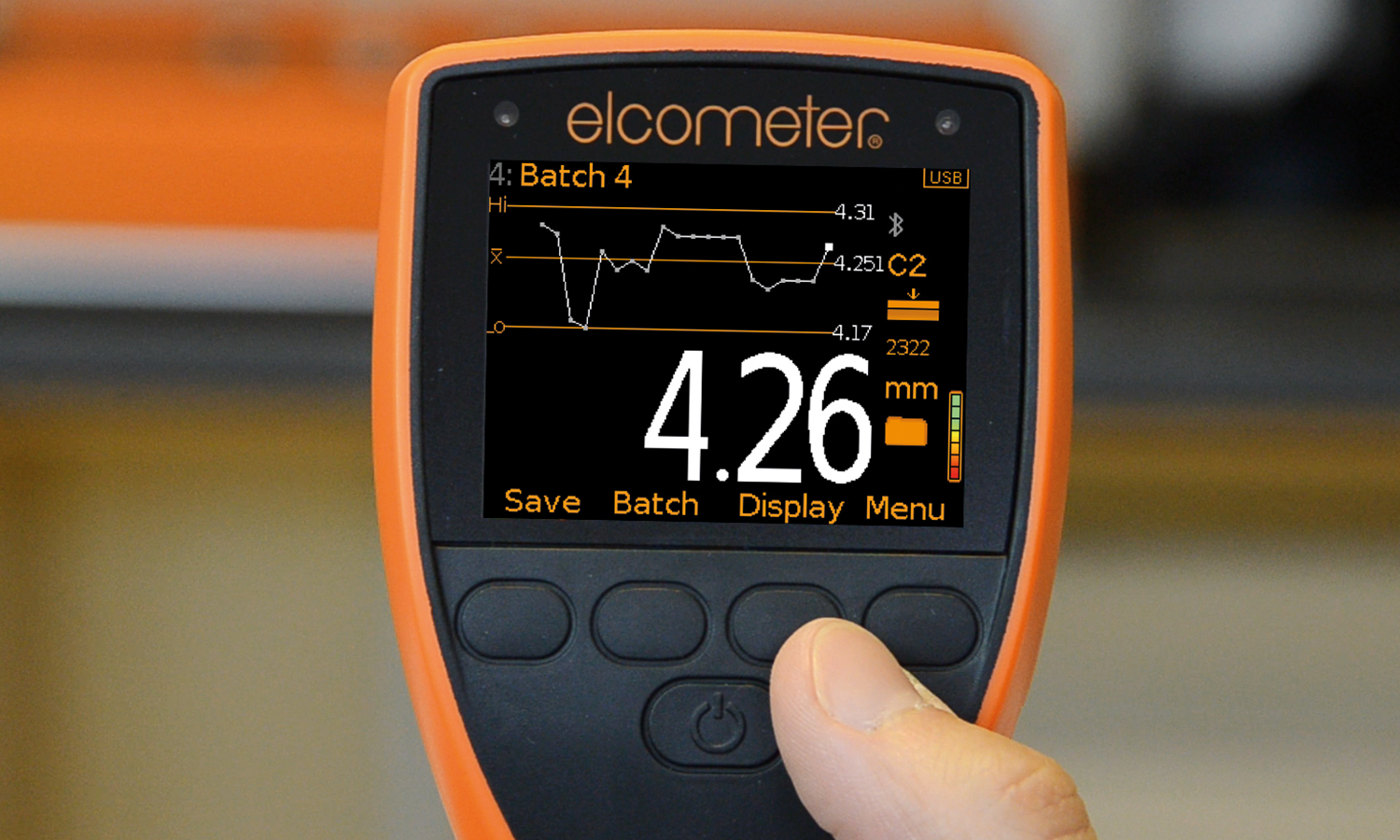

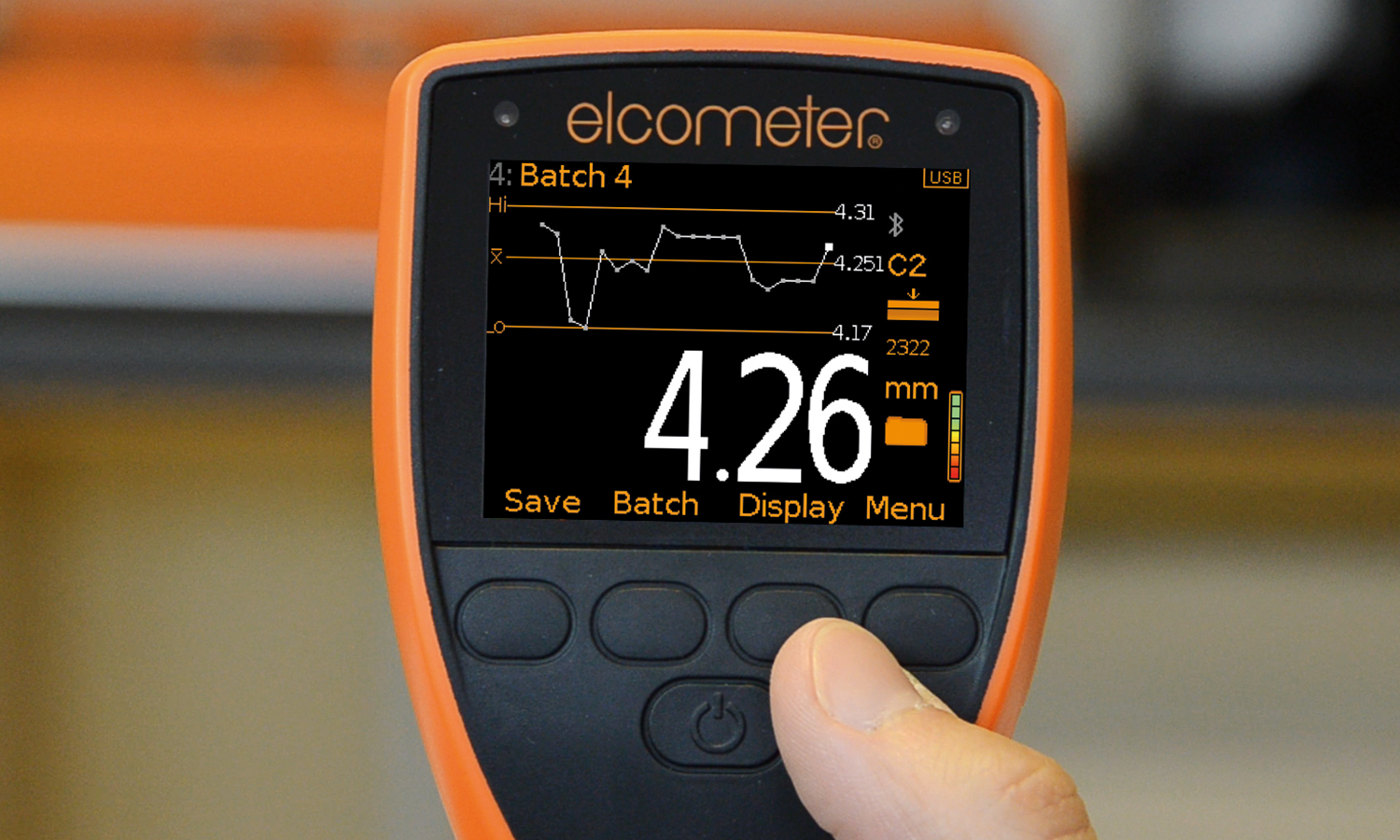

Create Instant Reports with ElcoMaster

It’s not just taking measurements but what you do with the collected data that matters.ElcoMaster Data Management Software, data reporting and graphsAs inspectors can spend up to 30% of their working week producing reports, ElcoMaster® saves time and money by producing professional bespoke reports in seconds - even when out on site.The Different Modes of Calibration

The Elcometer 500's user calibration adjustment procedures are fully traceable to National and International Standards.

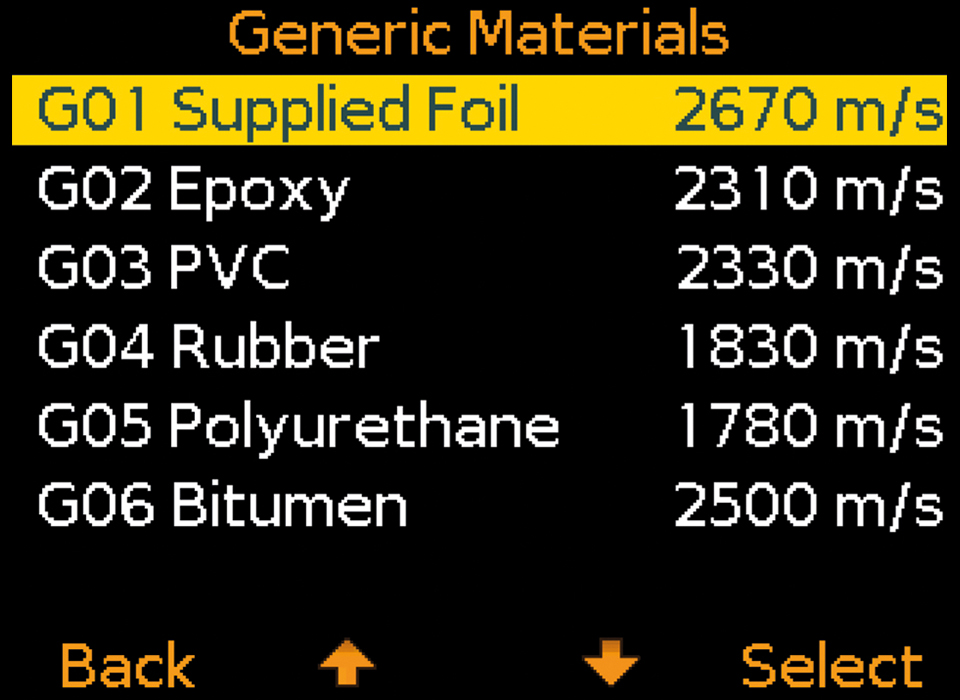

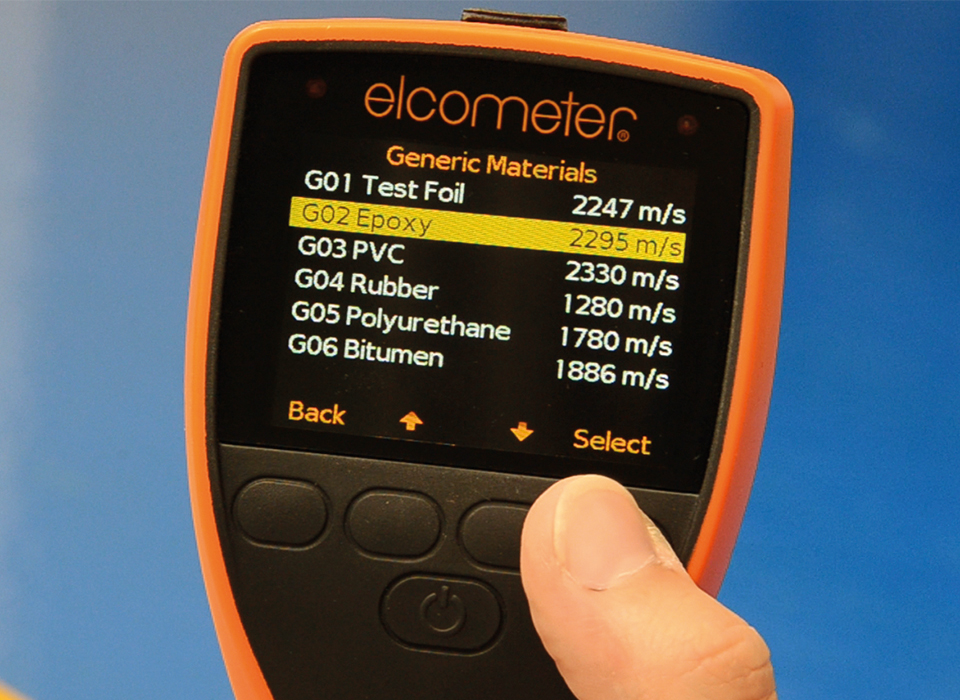

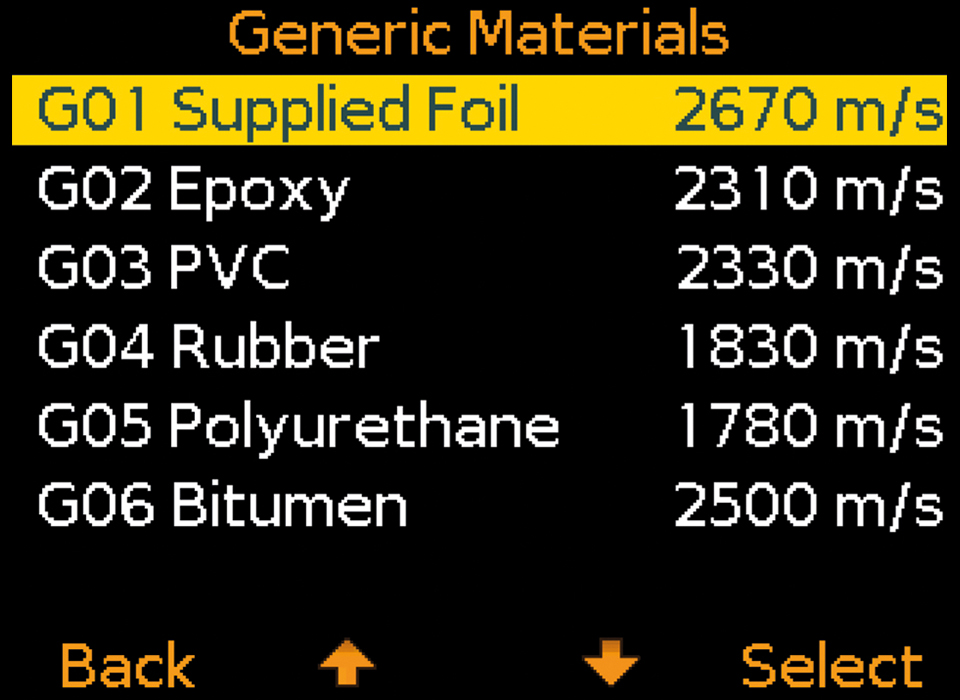

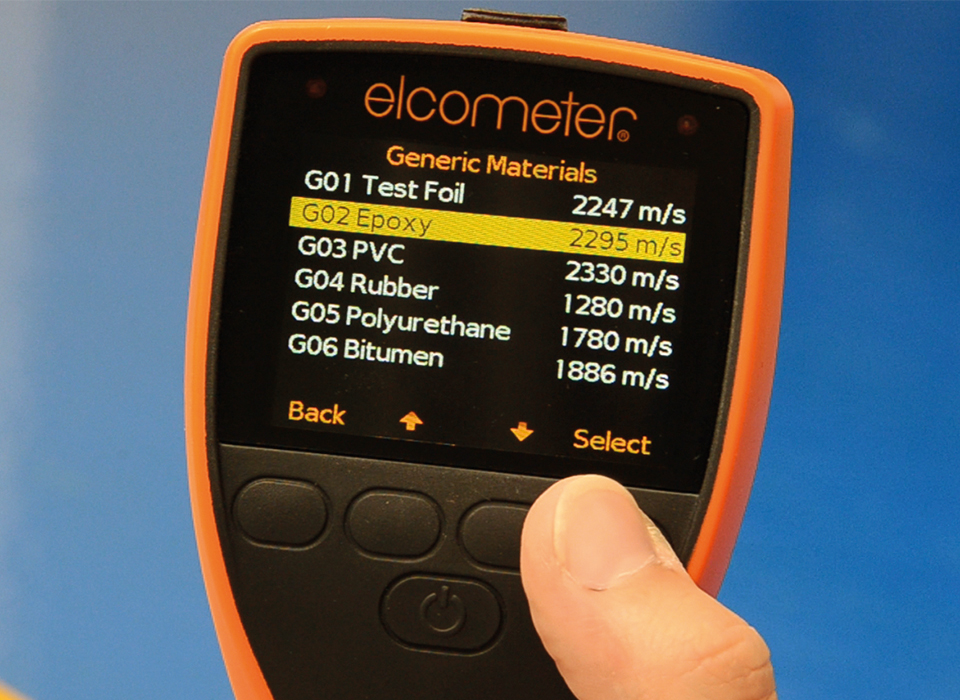

1. Coating Material Library

1. Coating Material LibraryThe Elcometer 500’s advanced measurement technology means that you no longer need to know how thick the coating should be before taking a reading, and you don’t need to set any measurement gates. Simply switch on the gauge, select the coating from the calibration library, and take a reading – it is that easy.

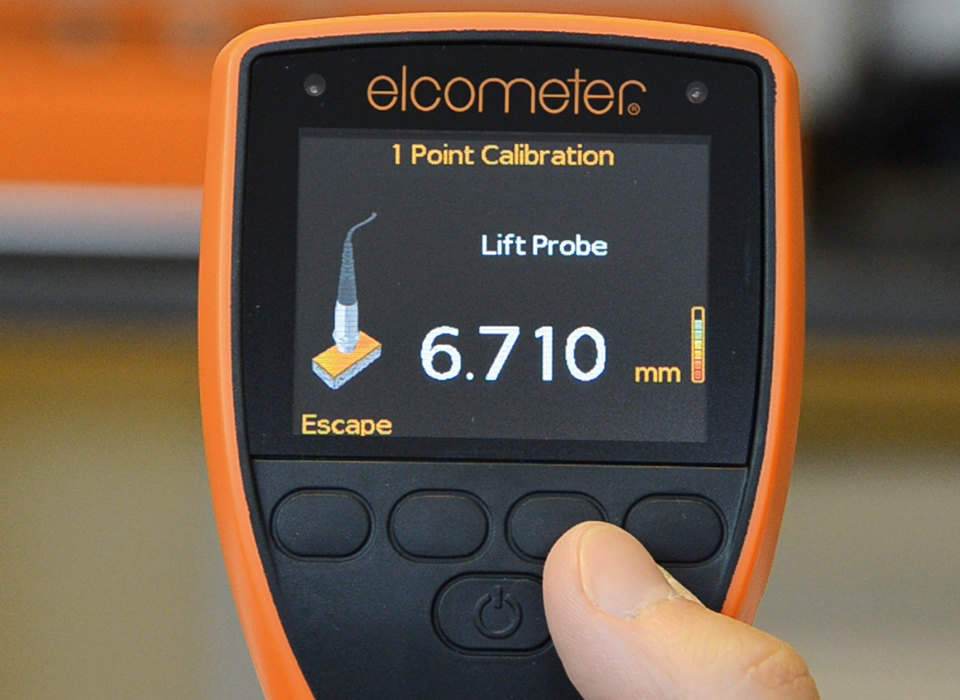

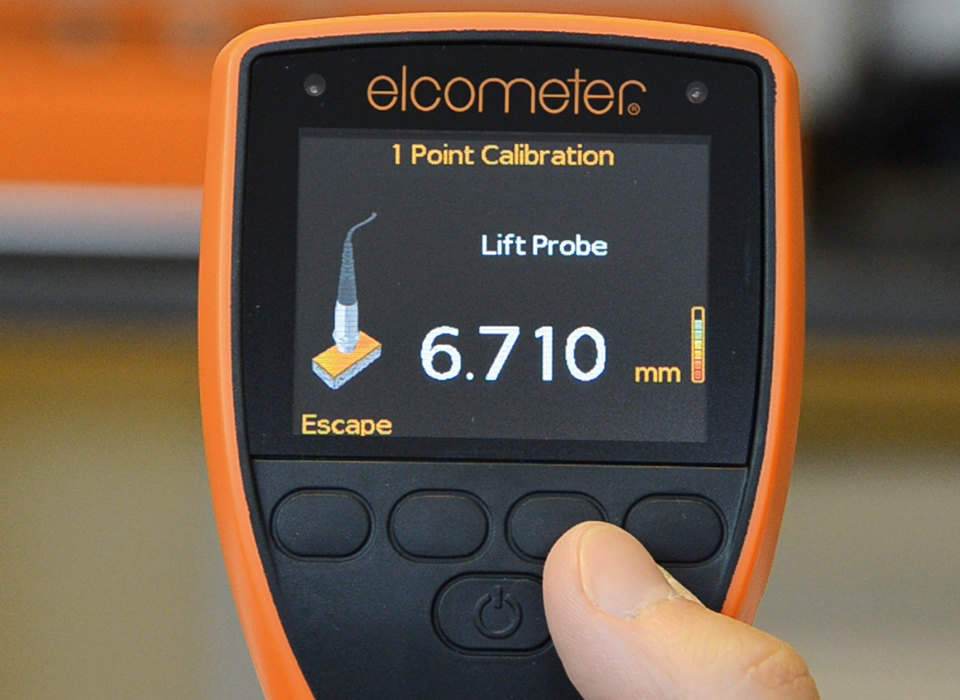

2. Material Thickness Calibration

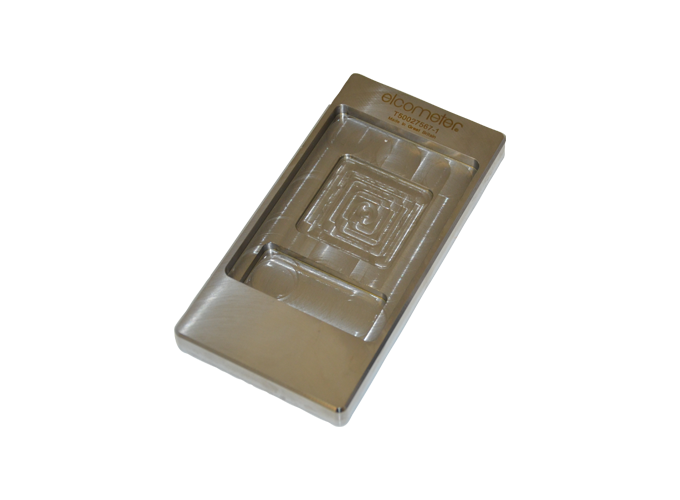

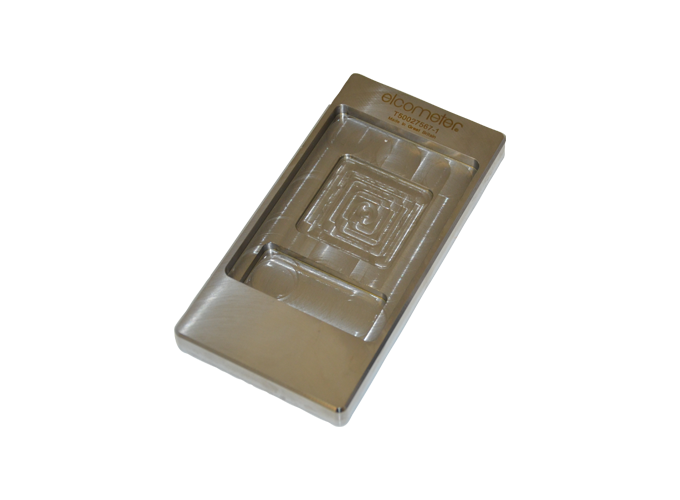

2. Material Thickness CalibrationTo obtain the greatest measurement accuracy, the Elcometer 500 can be calibrated using the known thickness of the coating to be measured. If a sample of known thickness is not available, the Elcometer 500 Coating Calibration Mould (CCM) can be used to create a coating of known thickness which is traceable to both National and International Standards.

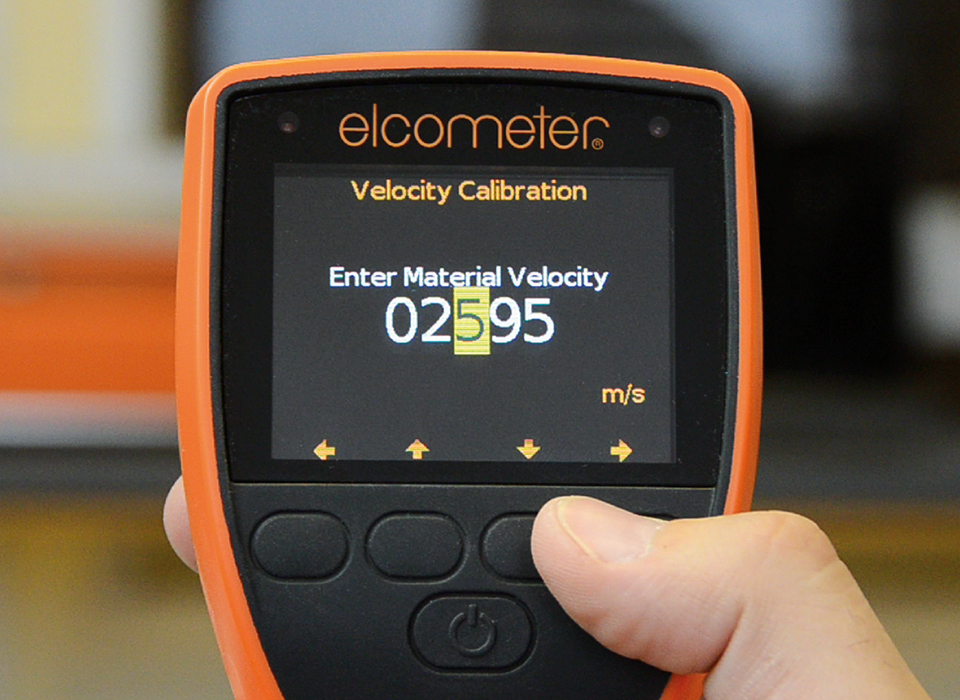

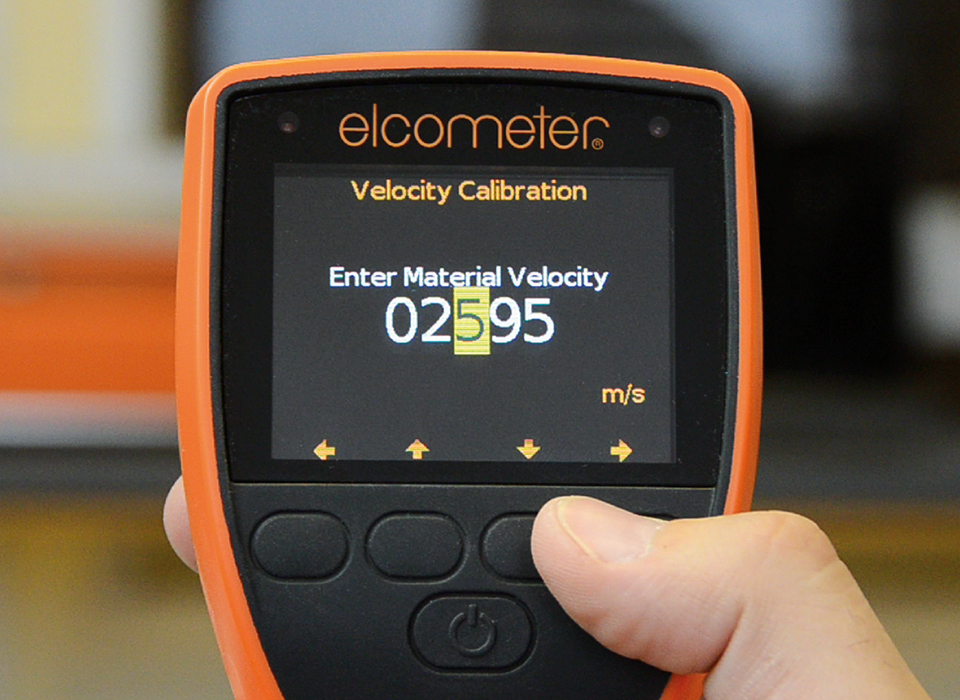

3. Sound Velocity Calibration

3. Sound Velocity CalibrationThe Elcometer 500 can be calibrated by entering the speed of sound from the Product Datasheet available from the coating manufacturer.

* Similar substrates include plasterboard, drywall, concrete block, brick etc.

‡Epoxy coatings, thickness on other materials may vary

*Compatible with iPod, iPhone and iPad.

-

- Product Features

-

Product FeaturesElcometer 500 Coating Thickness Gauge - Cementitious Substrates

Product Feature Standard Optional Model B Model T Fast, accurate reading rate; 60+ readings per minute Repeatable & reproducible measurements Easy to use menu structure; in 30+ languages Tough, impact, waterproof & dust resistant; equivalent to IP54 Bright colour screen; with automatic rotating display (0°, 90°, 180° & 270°) Scratch & solvent resistant display; 2.4” (6cm) TFT USB power supply; via PC Test certificate & 2 year gauge warranty1 Ambient light sensor; with adjustable auto brightness Automatic probe recognition Gauge software updates2; via ElcoMaster® software Data Output USB; to computer Bluetooth®; to computer, Android™ & iOS3 devices Measurement units; μm, mm, mils, inch Signal strength indicator User selectable reading resolution; Low & High reading resolution Display modes; user selectable Readings Readings & differential; reading and the offset from a set nominal difference Bar Graph Live reading trend graph; in Batch Mode Run chart; trend graph of last 20 readings User Selectable Statistics; Number of readings; η, Mean (average); x,Number of readings; η, Mean (average); x, Standard deviation; σ, Highest reading; Hi, Lowest reading; Lo, Coefficient of variation; CV% Nominal dry film thickness; NDFT, High & low limits; definable audible & visual alarms, Number of readings above high limit; Number of readings below low limit; Range; I Multiple calibration methods with on screen instructions; in 30+ languages Material selection; preset choice of materials or create own user defined materials Velocity entry; direct entry of a material’s sound-velocity 1 Point; using a coating sample of known thickness Calibration lock; with optional PIN Code Unlock Gauge memory; number of readings 100,000Number of batches; with unique calibrations 1,000Alpha-numeric batch names; user definable on the gauge Fixed Batch Size Mode; with batch linking Batch review graph Delete last reading Limits; 40 user definable audible & visual pass/fail warnings Live Reading Mode; transfer of individual readings to external device USBUSB & Bluetooth®Reading save function Date & time stamp Scan Mode ElcoMaster® software & USB cable Protective case Plastic transit case 1 The Elcometer 500 is supplied with a 1 year warranty against manufacturing defects. The warranty can be extended free of charge to 2 years within 60 days of purchase

2 Internet connection required

3 Visit www.elcometer.com/sdk to find out how to integrate Elcometer’s MFi certified products to your App.

-

- Technical Information

-

Technical SpecificationElcometer 500 Coating Thickness Gauge - Cementitious Substrates

Part Number Description Certificate A500C-B Elcometer 500 Coating Thickness Gauge Model B

A500C-T Elcometer 500 Coating Thickness Gauge Model T

A500-KIT1 Elcometer 500 Coatings on Concrete Inspection Kit

Operating Temperature -10 to 50°C (14 to 122°F) Power Supply 2 x AA batteries (rechargeable batteries can be used) Battery Life Alkaline: Approx. 15 hours Lithium: Approx. 28 hours Gauge Dimensions (h x w x d) 141 x 73 x 37mm (5.55 x 2.87 x 1.46”) without transducer Gauge Weight 161g (5.68oz) including batteries, without transducer Packing List Elcometer 500 Coating Thickness Gauge Model B / Model T

Elcometer 500 Coating Thickness Gauge, 4ml (0.14fl oz) bottle of probe tip oil, 120ml (4fl oz) bottle of ultrasonic couplant, 2 x AA batteries, protective case, transit case (Model T), wrist harness, 3 x screen protectors, ElcoMaster® software (Model T), USB cable (Model T), test certificate

Elcometer 500 Coatings on Concrete Inspection Kit

Elcometer 500 Model T Coating Thickness Gauge, C1 & C2 coating thickness probes, C1 & C2 probe measurement foils: 1, 2, 3 & 8mm (40, 80, 120 & 310mils), Elcometer 456 Model B Ferrous Integral Gauge, Elcometer 456 calibration foils: 0.5 & 1.5mm (20 & 60mils), 2 x coating calibration moulds, 120ml (4fl oz) bottle of ultrasonic couplant, 4ml (0.14fl oz) bottle of probe tip oil, transit case, ElcoMaster® software & USB cableProbe Range Scale C1 T500-C1 Elcometer 500 Scale C1 Probe

Range1 150 - 2,500μm (6 - 98mils) Accuracy2 ±2% or ±10μm (±2% or ±0.4mil) Resolution Low: 10μm, 0.01mm, 1mil or 0.001”

High: 1μm, 0.001mm, 0.1mil or 0.0001”Scale C2 T500-C2 Elcometer 500 Scale C2 Probe

Range1 750 - 9,000μm (30 - 355mils) Accuracy2 ±2% or ±10μm (±2% or ±0.4mil) Resolution Low: 10μm, 0.01mm, 1mil or 0.001”

High: 1μm, 0.001mm, 0.1mil or 0.0001”● Test Certificate supplied as standard

1 Epoxy coatings, thickness on other materials may vary

2 Whichever is greater

-

- Standards

-

StandardsElcometer 500 Coating Thickness Gauge - Cementitious Substrates

ASTM D6132, SSPC-PA 9, ISO 2808 Method 10

-

- Downloads

-

Downloads

-

Elcometer 500 Coatings on Concrete Multi-Lingual Instruction Manual

-

Elcometer 500 Coatings on Concrete Datasheet

-

Elcometer Probe Tip Oil Material Safety Data Sheet

-

Elcometer Ultrasonic Couplant (Clear) Material Safety Data Sheet

-

Elcometer Ultrasonic Couplant (Blue) Material Safety Data Sheet

-

Elcometer 500 Model B Concrete Coating Thickness Gauge Declaration of Conformity

-

Elcometer 500 Model B Coating Thickness Gauge - Concrete Substrates UKCA Declaration of Conformity

-

Elcometer 500 Model T Concrete Coating Thickness Gauge Declaration of Conformity

-

Elcometer 500 Model T Coating Thickness Gauge - Concrete Substrates UKCA Declaration of Conformity

- Part Numbers

-

Part NumbersElcometer 500 Coating Thickness Gauge - Cementitious SubstratesNo data found!!

-

Elcometer 500 Coating Thickness Gauge Model B

Elcometer 500 Coating Thickness Gauge Model B- Model: Model B

- Probe Option: Supplied Separately

- Part Number : A500C-B

-

Elcometer 500 Coating Thickness Gauge Model T

Elcometer 500 Coating Thickness Gauge Model T- Model: Model T

- Probe Option: Supplied Separately

- Part Number : A500C-T

-

Elcometer 500 Coatings on Concrete Inspection Kit

Elcometer 500 Coatings on Concrete Inspection Kit- Part Number : A500-KIT1

-

Elcometer 500 Scale C1 Probe

Elcometer 500 Scale C1 Probe- Part Number : T500-C1

-

Elcometer 500 Scale C2 Probe

Elcometer 500 Scale C2 Probe- Part Number : T500-C2

- Accessories

-

AccessoriesElcometer 500 Coating Thickness Gauge - Cementitious Substrates

Part Number: T50027602-1

Part Number: T50027602-1 Part Number: T50027602-2

Part Number: T50027602-2 Part Number: T50027604

Part Number: T50027604 Part Number: T92015701

Part Number: T92015701 Part Number: T99022255-13

Part Number: T99022255-13 Part Number: T99022255-13C

Part Number: T99022255-13C Part Number: T99022255-14

Part Number: T99022255-14 Part Number: T99022255-14C

Part Number: T99022255-14C Part Number: T50027567-1

Part Number: T50027567-1

Welcome to Elcometer.tv

Your ultimate training channel

- Home

- Coatings Inspection

- Coatings Inspection Division

- Dry Film Thickness

- Digital Coating Thickness Gauges

- Elcometer 500 Coating Thickness Gauge - Cementitious Substrates

Elcometer 500 Coating Thickness Gauge - Cementitious Substrates

- Protective Coatings

The Elcometer 500 Coating Thickness Gauge accurately measures the thickness of coatings on concrete and other similar substrates* - non destructively.

Fast

Measuring over 60 readings per minute in standard mode and over 140 readings per minute in scan mode, the Elcometer 500 Coating Thickness Gauge can significantly reduce your inspection times.

Intelligent

The Elcometer 500 Coatings on Concrete Gauge measurement probes are supplied with user replaceable probe tips. If the tip is damaged or wears during use you can replace it and carry on.

The gauge even informs you when you need to change the probe tip, maximising inspection time.

Reliable

The Elcometer 500 Coating Thickness Gauge will only display the coating thickness reading if the signal strength indicator turns green, preventing false or incorrect readings.

If the coating thickness is outside the measurement range, the Elcometer 500 Concrete Coating Thickness Gauge tells you on the display.

Summary

Elcometer 500 Coating Thickness Gauge - Cementitious Substrates

Fast and accurate, the Elcometer 500 Coating Thickness Gauge takes repeatable and reproducible dry film thickness measurements of coatings on concrete up to 10mm‡ thick – without damaging the coating.

Taking over 60 readings per minute in standard mode and 140+ readings per minute in scan mode; the Elcometer 500 Coating Thickness Gauge allows users to inspect more coatings in less time. With a choice of intelligent, ergonomic probes, designed for continuous use and field replaceable probe tips you can inspect all day, everyday.

The built in signal strength indicator on the Elcometer 500 Coatings on Concrete Gauge prevents false or incorrect readings, as the gauge only displays the coating thickness measurement if the signal strength indicator goes green.

Robust, ergonomic and sealed against dirt and water, equivalent to a rating of IP54, the Elcometer 500 Concrete Coating Thickness Gauge has been designed to work in harsh environments.

Incredibly easy to use, the Elcometer 500 Coating Thickness Gauge for concrete can be used in accordance with ASTM D6132, SSPC PA9 & ISO 2808 Method 10.

Compatible with ElcoMaster® software and ElcoMaster® Mobile App, individual coating thickness measurements can be transferred via USB or Bluetooth® to PC or a mobile device for analysis and instant report generation.

Downloads-

Elcometer 500 Coatings on Concrete Multi-Lingual Instruction Manual

-

Elcometer 500 Coatings on Concrete Datasheet

-

Elcometer Probe Tip Oil Material Safety Data Sheet

-

Elcometer Ultrasonic Couplant (Clear) Material Safety Data Sheet

-

Elcometer Ultrasonic Couplant (Blue) Material Safety Data Sheet

-

Elcometer 500 Model B Concrete Coating Thickness Gauge Declaration of Conformity

-

Elcometer 500 Model B Coating Thickness Gauge - Concrete Substrates UKCA Declaration of Conformity

-

Elcometer 500 Model T Concrete Coating Thickness Gauge Declaration of Conformity

-

Elcometer 500 Model T Coating Thickness Gauge - Concrete Substrates UKCA Declaration of Conformity

Key Features

Elcometer 500 Coating Thickness Gauge - Cementitious Substrates

Easy to Use

There is no need to set up gates, range values or know the thickness of the coating, simply select the coating material from the gauge library and start measuring.

Ergonomic

The Elcometer 500 Coatings on Concrete Thickness Gauge and intelligent probes have all been ergonomically designed for continuous use. No force is required to take a reading.

Rugged

Robust, ergonomic and sealed against dirt and water, equivalent to a rating of IP54, the Elcometer 500 Coating Thickness Gauge has been designed to work in harsh environments, making it the ideal gauge for the laboratory or the job site.

Create Instant Reports with ElcoMaster

It’s not just taking measurements but what you do with the collected data that matters.ElcoMaster Data Management Software, data reporting and graphsAs inspectors can spend up to 30% of their working week producing reports, ElcoMaster® saves time and money by producing professional bespoke reports in seconds - even when out on site.The Different Modes of Calibration

The Elcometer 500's user calibration adjustment procedures are fully traceable to National and International Standards.

1. Coating Material Library

1. Coating Material LibraryThe Elcometer 500’s advanced measurement technology means that you no longer need to know how thick the coating should be before taking a reading, and you don’t need to set any measurement gates. Simply switch on the gauge, select the coating from the calibration library, and take a reading – it is that easy.

2. Material Thickness Calibration

2. Material Thickness CalibrationTo obtain the greatest measurement accuracy, the Elcometer 500 can be calibrated using the known thickness of the coating to be measured. If a sample of known thickness is not available, the Elcometer 500 Coating Calibration Mould (CCM) can be used to create a coating of known thickness which is traceable to both National and International Standards.

3. Sound Velocity Calibration

3. Sound Velocity CalibrationThe Elcometer 500 can be calibrated by entering the speed of sound from the Product Datasheet available from the coating manufacturer.

* Similar substrates include plasterboard, drywall, concrete block, brick etc.

‡Epoxy coatings, thickness on other materials may vary

*Compatible with iPod, iPhone and iPad.

Product FeaturesElcometer 500 Coating Thickness Gauge - Cementitious SubstratesProduct Feature Standard Optional Model B Model T Fast, accurate reading rate; 60+ readings per minute Repeatable & reproducible measurements Easy to use menu structure; in 30+ languages Tough, impact, waterproof & dust resistant; equivalent to IP54 Bright colour screen; with automatic rotating display (0°, 90°, 180° & 270°) Scratch & solvent resistant display; 2.4” (6cm) TFT USB power supply; via PC Test certificate & 2 year gauge warranty1 Ambient light sensor; with adjustable auto brightness Automatic probe recognition Gauge software updates2; via ElcoMaster® software Data Output USB; to computer Bluetooth®; to computer, Android™ & iOS3 devices Measurement units; μm, mm, mils, inch Signal strength indicator User selectable reading resolution; Low & High reading resolution Display modes; user selectable Readings Readings & differential; reading and the offset from a set nominal difference Bar Graph Live reading trend graph; in Batch Mode Run chart; trend graph of last 20 readings User Selectable Statistics; Number of readings; η, Mean (average); x,Number of readings; η, Mean (average); x, Standard deviation; σ, Highest reading; Hi, Lowest reading; Lo, Coefficient of variation; CV% Nominal dry film thickness; NDFT, High & low limits; definable audible & visual alarms, Number of readings above high limit; Number of readings below low limit; Range; I Multiple calibration methods with on screen instructions; in 30+ languages Material selection; preset choice of materials or create own user defined materials Velocity entry; direct entry of a material’s sound-velocity 1 Point; using a coating sample of known thickness Calibration lock; with optional PIN Code Unlock Gauge memory; number of readings 100,000Number of batches; with unique calibrations 1,000Alpha-numeric batch names; user definable on the gauge Fixed Batch Size Mode; with batch linking Batch review graph Delete last reading Limits; 40 user definable audible & visual pass/fail warnings Live Reading Mode; transfer of individual readings to external device USBUSB & Bluetooth®Reading save function Date & time stamp Scan Mode ElcoMaster® software & USB cable Protective case Plastic transit case 1 The Elcometer 500 is supplied with a 1 year warranty against manufacturing defects. The warranty can be extended free of charge to 2 years within 60 days of purchase

2 Internet connection required

3 Visit www.elcometer.com/sdk to find out how to integrate Elcometer’s MFi certified products to your App.Technical SpecificationElcometer 500 Coating Thickness Gauge - Cementitious SubstratesPart Number Description Certificate A500C-B Elcometer 500 Coating Thickness Gauge Model B

A500C-T Elcometer 500 Coating Thickness Gauge Model T

A500-KIT1 Elcometer 500 Coatings on Concrete Inspection Kit

Operating Temperature -10 to 50°C (14 to 122°F) Power Supply 2 x AA batteries (rechargeable batteries can be used) Battery Life Alkaline: Approx. 15 hours Lithium: Approx. 28 hours Gauge Dimensions (h x w x d) 141 x 73 x 37mm (5.55 x 2.87 x 1.46”) without transducer Gauge Weight 161g (5.68oz) including batteries, without transducer Packing List Elcometer 500 Coating Thickness Gauge Model B / Model T

Elcometer 500 Coating Thickness Gauge, 4ml (0.14fl oz) bottle of probe tip oil, 120ml (4fl oz) bottle of ultrasonic couplant, 2 x AA batteries, protective case, transit case (Model T), wrist harness, 3 x screen protectors, ElcoMaster® software (Model T), USB cable (Model T), test certificate

Elcometer 500 Coatings on Concrete Inspection Kit

Elcometer 500 Model T Coating Thickness Gauge, C1 & C2 coating thickness probes, C1 & C2 probe measurement foils: 1, 2, 3 & 8mm (40, 80, 120 & 310mils), Elcometer 456 Model B Ferrous Integral Gauge, Elcometer 456 calibration foils: 0.5 & 1.5mm (20 & 60mils), 2 x coating calibration moulds, 120ml (4fl oz) bottle of ultrasonic couplant, 4ml (0.14fl oz) bottle of probe tip oil, transit case, ElcoMaster® software & USB cableProbe Range Scale C1 T500-C1 Elcometer 500 Scale C1 Probe

Range1 150 - 2,500μm (6 - 98mils) Accuracy2 ±2% or ±10μm (±2% or ±0.4mil) Resolution Low: 10μm, 0.01mm, 1mil or 0.001”

High: 1μm, 0.001mm, 0.1mil or 0.0001”Scale C2 T500-C2 Elcometer 500 Scale C2 Probe

Range1 750 - 9,000μm (30 - 355mils) Accuracy2 ±2% or ±10μm (±2% or ±0.4mil) Resolution Low: 10μm, 0.01mm, 1mil or 0.001”

High: 1μm, 0.001mm, 0.1mil or 0.0001”● Test Certificate supplied as standard

1 Epoxy coatings, thickness on other materials may vary

2 Whichever is greaterStandardsElcometer 500 Coating Thickness Gauge - Cementitious SubstratesASTM D6132, SSPC-PA 9, ISO 2808 Method 10

Part NumbersElcometer 500 Coating Thickness Gauge - Cementitious SubstratesNo data found!!-

Elcometer 500 Coating Thickness Gauge Model B

Elcometer 500 Coating Thickness Gauge Model B- Model: Model B

- Probe Option: Supplied Separately

- Part Number : A500C-B

-

Elcometer 500 Coating Thickness Gauge Model T

Elcometer 500 Coating Thickness Gauge Model T- Model: Model T

- Probe Option: Supplied Separately

- Part Number : A500C-T

-

Elcometer 500 Coatings on Concrete Inspection Kit

Elcometer 500 Coatings on Concrete Inspection Kit- Part Number : A500-KIT1

-

Elcometer 500 Scale C1 Probe

Elcometer 500 Scale C1 Probe- Part Number : T500-C1

-

Elcometer 500 Scale C2 Probe

Elcometer 500 Scale C2 Probe- Part Number : T500-C2

Welcome to Elcometer.tv

Your ultimate training channelAccessoriesElcometer 500 Coating Thickness Gauge - Cementitious Substrates Part Number: T50027602-1

Part Number: T50027602-1 Part Number: T50027602-2

Part Number: T50027602-2 Part Number: T50027604

Part Number: T50027604 Part Number: T92015701

Part Number: T92015701 Part Number: T99022255-13

Part Number: T99022255-13 Part Number: T99022255-13C

Part Number: T99022255-13C Part Number: T99022255-14

Part Number: T99022255-14 Part Number: T99022255-14C

Part Number: T99022255-14C Part Number: T50027567-1

Part Number: T50027567-1

-

-