Elcometer 266 Holiday Detector

- Protective Coatings

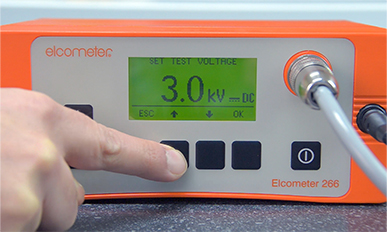

The Elcometer 266 Holiday Detector revolutionises high voltage DC testing of coatings porosity detection making it safer, easier and more reliable than ever before.

- Summary

-

Summary

-

User Friendly

The voltage calculator automatically sets the correct voltage from your coating thickness value. No need to use look up tables.

Safe

Featuring a dual safety switch on the handle to avoid accidental switch on and specialised ribbing, the Elcometer 266 Holiday Detector provides superior protection.

Versatile

To change the maximum voltage range, select a different handle; 5kV, 15kV or 30kV DC or 30kV DC continuous.

The Elcometer 266 holiday detector can be used to test porosity on coatings up to 7.5mm (300 mils) thick and is ideal for inspecting coatings on pipelines and other protective coatings.

This holiday tester features a built-in voltage calculator which will determine and set the correct test voltage based upon the test standard and the thickness of the coating being tested.

-

- Key Features

-

Key Features

Elcometer 266 Holiday Detector

- the voltage calculator automatically sets the correct voltage from your coating thickness value

- Adjustable Voltage:

- 0.5kV - 1kV in 50V steps

- 1kV to 30kV in 100V steps

- Dual safety switch on the handle to avoid accidental switch on (Grey/orange probe handles only)

- Internal Voltmeter/ Jeep tester ensures that the test voltage equals the selected voltage

- Visual and audible alarms, Bright LEDs on the handle, as well as a loud buzzer, clearly indicate when a holiday is detected

- To change the maximum voltage range, select a different handle; 5kV, 15kV or 30kV DC or 30kV DC continuous

- A wide range of probe brushes and rolling springs available

Elcometer 266 DC Holiday Detector Features Explained

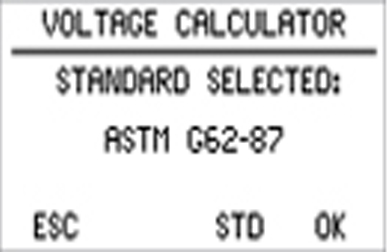

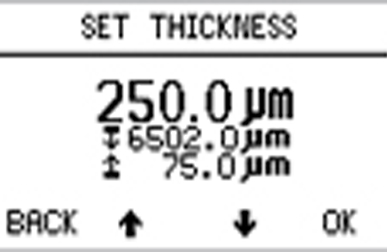

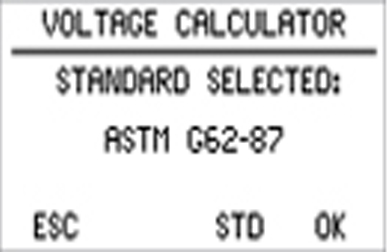

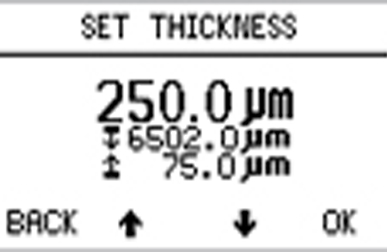

Voltage Calculator

Automatically sets the correct voltage from your coating thickness value. No need to use lookup tables. Enter the test standard and the coating thickness and the gauge will automatically programme the correct voltage.

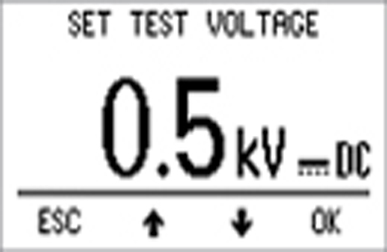

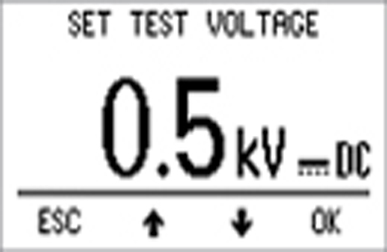

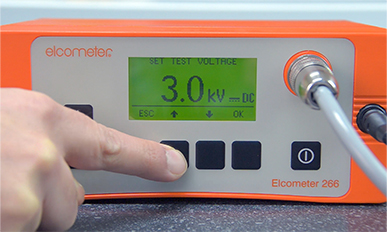

Adjustable Voltage

No need for screwdriver: 0.5kV - 1kV in 50V steps, 1kV to 30kV in 100V steps. Sensitivity to current can be manually preset or automatically adjusted by the gauge for partially conductive coatings.

Internal Voltmeter/ Jeep tester

Ensures that the test voltage equals the selected voltage. The closed loop system ensures that the generated test voltage is accurately measured and continuously controlled, regardless of climatic conditions.

Interchangeable probe handles

Available, 5kV, 15kV and 30kV DC and DC continuous versions.

Audible and visual alarms

Visual and audible alarms are activated when a flaw is detected. Bright LEDs on the handle, as well as a loud audible alarm, clearly indicate if the gauge is on (Red) and when a spark is detected (Blue).

Battery pack

Can be recharged inside or outside the gauge for continued use. Batteries are fully charged within 4 hours and provide up to 40 hours continuous use between charges.

Universal probe adaptors

Enables the Elcometer 266 Holiday Tester to work with all major holiday detector accessories.

Screen display

A large, backlit display enables easy viewing even in dark environments. When a flaw is detected the backlight also flashes.

Second hand grip

The optional second handgrip is designed for two handed use without compromising its safety. Ideal for testing pipes and tank floors.

Elcometer 266 DC Holiday Detector Safety Features

- Dual safety switches on handle to avoid accidental switch on. 2-stage safety switch ensures that if the Elcometer 266 Holiday Detector handle is not gripped, the handle will switch off.

- Specialised ribbing provides superior protection while an optional second hand grip is ideal for two handed use. This holiday detector has been specifically designed to meet standard EN61010.

- The speaker on the holiday tester clearly emits a ticking noise to indicate that there is a voltage at the handle.

- A loud audible alarm is activated when a spark is detected. The beep volume can also be adjusted to ensure it can be heard - even in noisy environments.

-

- Technical Information

-

Technical SpecificationElcometer 266 Holiday Detector

Description Part Number Certificate Elcometer 266* D266----4

High Voltage Output Accuracy ±5% or ±50V below 1000 Volts Operating Temperature 0°C to 50°C (32°F to 120°F) Power Supply Rechargeable Battery Pack: battery fully charged within 4 hours Measured Current Flow Accuracy ±5% of full scale ; 0 - 100μA maximum Output Current Typical Battery Life - Backlight Off (On) DC5: 40 (20) hours

DC15: 20 (15) hours

DC30: 10 (8) hoursInstrument Case Dimensions Waterproof, ABS case: 520 x 370 x 125mm (20.5 x 14.5 x 5”) Weight Base unit (including battery pack): 1.2kg (2.7lb), Handle: 0.6kg (1.3lb) Packing List Elcometer 266 DC Holiday Detector, battery pack, curly connection cable for high voltage handle, 10m (32") signal return lead, battery charger with UK, EUR, US and AUS plugs, band brush, shoulder strap, tough plastic carry case and operating instructions * The Elcometer 266 does not include the probe handle; please select the required handle from the accessories

○ Optional Calibration Certificate available.

-

- Standards

-

StandardsElcometer 266 Holiday Detector

ANSI/AWWA C213, AS 3894.1, ASTM C 536, ASTM C 537, ASTM D 4787, ASTM D 5162-B, ASTM G 62-B, BS1344-11, DIN 55670, EN 14430, ISO 2746, ISO 29601, JIS K 6766, NACE RP0274, NACE RP0188, NACE RP0190, NACE RP0490, NACE SP0188, NACE SP0490

Standards in grey have been superseded but are still recognised in some industries.

-

- Downloads

-

Downloads

- Part Numbers

-

Part NumbersElcometer 266 Holiday DetectorNo data found!!

-

Elcometer 266 Holiday Detector

Elcometer 266 Holiday Detector- Part Number : D266----4

-

Elcometer 266 Holiday Detector

Elcometer 266 Holiday Detector- Part Number : D266----4C

- Accessories

-

AccessoriesElcometer 266 Holiday Detector

Part Number: T26620033-1

Part Number: T26620033-1 Part Number: T26620033-2

Part Number: T26620033-2 Part Number: T26620033-3

Part Number: T26620033-3 Part Number: T26620033-4

Part Number: T26620033-4 Part Number: T26620081

Part Number: T26620081 Part Number: T26620033-1C

Part Number: T26620033-1C Part Number: T26620033-2C

Part Number: T26620033-2C Part Number: T26620033-3C

Part Number: T26620033-3C Part Number: T26620033-4C

Part Number: T26620033-4C

-

- Home

- Elcometer 266 Holiday Detector

Elcometer 266 Holiday Detector

- Protective Coatings

The Elcometer 266 Holiday Detector revolutionises high voltage DC testing of coatings porosity detection making it safer, easier and more reliable than ever before.

User Friendly

The voltage calculator automatically sets the correct voltage from your coating thickness value. No need to use look up tables.

Safe

Featuring a dual safety switch on the handle to avoid accidental switch on and specialised ribbing, the Elcometer 266 Holiday Detector provides superior protection.

Versatile

To change the maximum voltage range, select a different handle; 5kV, 15kV or 30kV DC or 30kV DC continuous.

Summary

Elcometer 266 Holiday Detector

The Elcometer 266 holiday detector can be used to test porosity on coatings up to 7.5mm (300 mils) thick and is ideal for inspecting coatings on pipelines and other protective coatings.

This holiday tester features a built-in voltage calculator which will determine and set the correct test voltage based upon the test standard and the thickness of the coating being tested.

Key Features

Elcometer 266 Holiday Detector

- the voltage calculator automatically sets the correct voltage from your coating thickness value

- Adjustable Voltage:

- 0.5kV - 1kV in 50V steps

- 1kV to 30kV in 100V steps

- Dual safety switch on the handle to avoid accidental switch on (Grey/orange probe handles only)

- Internal Voltmeter/ Jeep tester ensures that the test voltage equals the selected voltage

- Visual and audible alarms, Bright LEDs on the handle, as well as a loud buzzer, clearly indicate when a holiday is detected

- To change the maximum voltage range, select a different handle; 5kV, 15kV or 30kV DC or 30kV DC continuous

- A wide range of probe brushes and rolling springs available

Elcometer 266 DC Holiday Detector Features Explained

Voltage Calculator

Automatically sets the correct voltage from your coating thickness value. No need to use lookup tables. Enter the test standard and the coating thickness and the gauge will automatically programme the correct voltage.

Adjustable Voltage

No need for screwdriver: 0.5kV - 1kV in 50V steps, 1kV to 30kV in 100V steps. Sensitivity to current can be manually preset or automatically adjusted by the gauge for partially conductive coatings.

Internal Voltmeter/ Jeep tester

Ensures that the test voltage equals the selected voltage. The closed loop system ensures that the generated test voltage is accurately measured and continuously controlled, regardless of climatic conditions.

Interchangeable probe handles

Available, 5kV, 15kV and 30kV DC and DC continuous versions.

Audible and visual alarms

Visual and audible alarms are activated when a flaw is detected. Bright LEDs on the handle, as well as a loud audible alarm, clearly indicate if the gauge is on (Red) and when a spark is detected (Blue).

Battery pack

Can be recharged inside or outside the gauge for continued use. Batteries are fully charged within 4 hours and provide up to 40 hours continuous use between charges.

Universal probe adaptors

Enables the Elcometer 266 Holiday Tester to work with all major holiday detector accessories.

Screen display

A large, backlit display enables easy viewing even in dark environments. When a flaw is detected the backlight also flashes.

Second hand grip

The optional second handgrip is designed for two handed use without compromising its safety. Ideal for testing pipes and tank floors.

Elcometer 266 DC Holiday Detector Safety Features

- Dual safety switches on handle to avoid accidental switch on. 2-stage safety switch ensures that if the Elcometer 266 Holiday Detector handle is not gripped, the handle will switch off.

- Specialised ribbing provides superior protection while an optional second hand grip is ideal for two handed use. This holiday detector has been specifically designed to meet standard EN61010.

- The speaker on the holiday tester clearly emits a ticking noise to indicate that there is a voltage at the handle.

- A loud audible alarm is activated when a spark is detected. The beep volume can also be adjusted to ensure it can be heard - even in noisy environments.

Technical SpecificationElcometer 266 Holiday DetectorDescription Part Number Certificate Elcometer 266* D266----4

High Voltage Output Accuracy ±5% or ±50V below 1000 Volts Operating Temperature 0°C to 50°C (32°F to 120°F) Power Supply Rechargeable Battery Pack: battery fully charged within 4 hours Measured Current Flow Accuracy ±5% of full scale ; 0 - 100μA maximum Output Current Typical Battery Life - Backlight Off (On) DC5: 40 (20) hours

DC15: 20 (15) hours

DC30: 10 (8) hoursInstrument Case Dimensions Waterproof, ABS case: 520 x 370 x 125mm (20.5 x 14.5 x 5”) Weight Base unit (including battery pack): 1.2kg (2.7lb), Handle: 0.6kg (1.3lb) Packing List Elcometer 266 DC Holiday Detector, battery pack, curly connection cable for high voltage handle, 10m (32") signal return lead, battery charger with UK, EUR, US and AUS plugs, band brush, shoulder strap, tough plastic carry case and operating instructions * The Elcometer 266 does not include the probe handle; please select the required handle from the accessories

○ Optional Calibration Certificate available.StandardsElcometer 266 Holiday DetectorANSI/AWWA C213, AS 3894.1, ASTM C 536, ASTM C 537, ASTM D 4787, ASTM D 5162-B, ASTM G 62-B, BS1344-11, DIN 55670, EN 14430, ISO 2746, ISO 29601, JIS K 6766, NACE RP0274, NACE RP0188, NACE RP0190, NACE RP0490, NACE SP0188, NACE SP0490

Standards in grey have been superseded but are still recognised in some industries.

Part NumbersElcometer 266 Holiday DetectorNo data found!!-

Elcometer 266 Holiday Detector

Elcometer 266 Holiday Detector- Part Number : D266----4

-

Elcometer 266 Holiday Detector

Elcometer 266 Holiday Detector- Part Number : D266----4C

AccessoriesElcometer 266 Holiday Detector Part Number: T26620033-1

Part Number: T26620033-1 Part Number: T26620033-2

Part Number: T26620033-2 Part Number: T26620033-3

Part Number: T26620033-3 Part Number: T26620033-4

Part Number: T26620033-4 Part Number: T26620081

Part Number: T26620081 Part Number: T26620033-1C

Part Number: T26620033-1C Part Number: T26620033-2C

Part Number: T26620033-2C Part Number: T26620033-3C

Part Number: T26620033-3C Part Number: T26620033-4C

Part Number: T26620033-4C

- Part Numbers

-