Elcometer 456 Coating Thickness Gauge - Separate

- Protective Coatings

- Industrial Finishing

The Elcometer 456 Coating Thickness Gauge is available with a wide range of separate interchangeable probes; providing greater coating thickness measurement flexibility on metal substrates.

- Summary

-

Summary

-

Fast Coating Thickness Measurements

The Elcometer 456 Coating Thickness Gauge enhances efficiency by providing 70+ dry film thickness readings per minute (140+ per minute when using a scan probe). The Elcometer 456 mil gage has multiple calibration memories and alpha numeric batch identification.

An Accurate Coating Thickness Gauge

Accuracy is key when taking coating thickness measurements, that's why the Elcometer 456 paint meter is designed to measure dry film thickness on smooth, rough, thin and curved surfaces to ±1% in accordance with National & International Standards.

Powerful Memory & Data Output

The Elcometer 456 Coating Thickness Gauge stores up to 150,000 readings in 2,500 batches and has the ability to measure up to 31mm (1,220mils) of coating on metal substrates. Its USB and Bluetooth® data output make it compatible with ElcoMaster® Data Management Software for fast and accurate coating inspection reporting.

The Elcometer 456 Coating Thickness Gauge is available in three different models. Each coating thickness gauge provides the user with increasing functionality - from the entry level Elcometer 456 Paint Thickness Gauge Model B, to the top of the range Elcometer 456 Film Thickness Gauge Model T.

Separate coating thickness gauge models, with their wide range of probes, provide even greater dry film thickness measurement flexibility.

Compatible with ElcoMaster® software and ElcoMaster® Mobile App, individual coating thickness measurements can be transferred via USB or Bluetooth® to PC or a mobile device for analysis and instant report generation.

For more information on What is a Coating Thickness Gauge, click here

Elcometer 456 Integral Coating Thickness Gauge

Integral dry film thickness gauges are ideal for single handed operation as the wide footprint of the Bigfoot™ internal probe provides greater stability during coating thickness measurement

ElcoMaster® Data Management Software

Inspectors can spend up to 30% of their working week producing reports. ElcoMaster® Software saves time and money by producing professional bespoke reports - even when out on site.

-

- Key Features

-

Key Features

Elcometer 456 Coating Thickness Gauge - Separate

An easy to use Coating Thickness Gauge

Designed with large buttons and a colour screen, the Elcometer 456 Coating Thickness Gauge allows easy measurements thanks to its enhanced usability. The paint gauge features an LCD screen with auto rotate and is factory calibrated with high and low reading limit indicators in multiple languages.

Reliablilty You Can Trust

Designed to last, this heavy duty, impact resistant Coating Thickness Gauge is supplied with fully traceable test certificates and an Elcometer 2 year gauge warranty*.

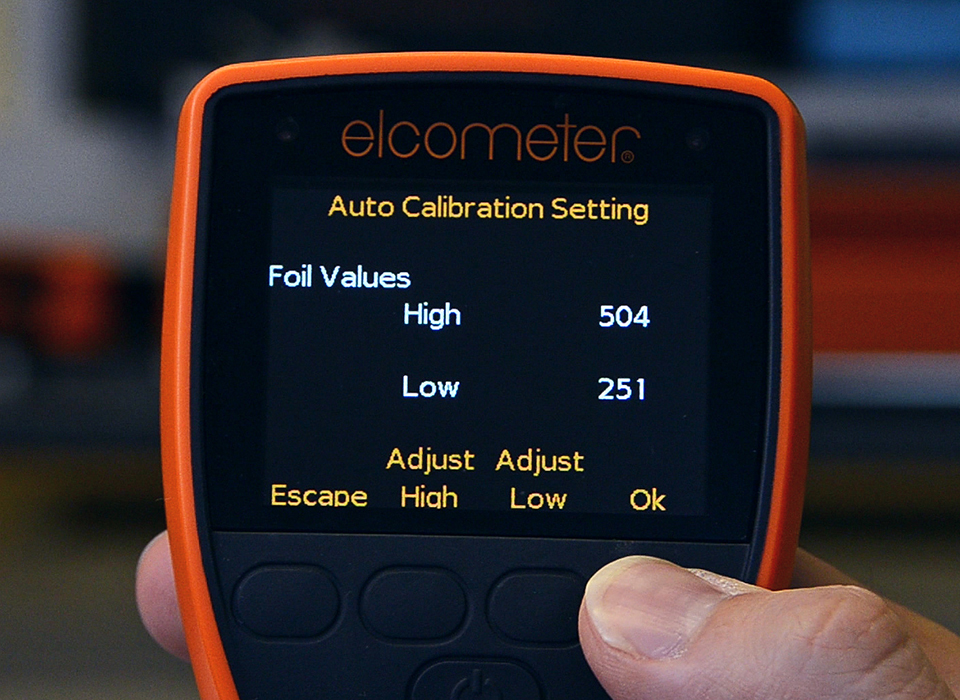

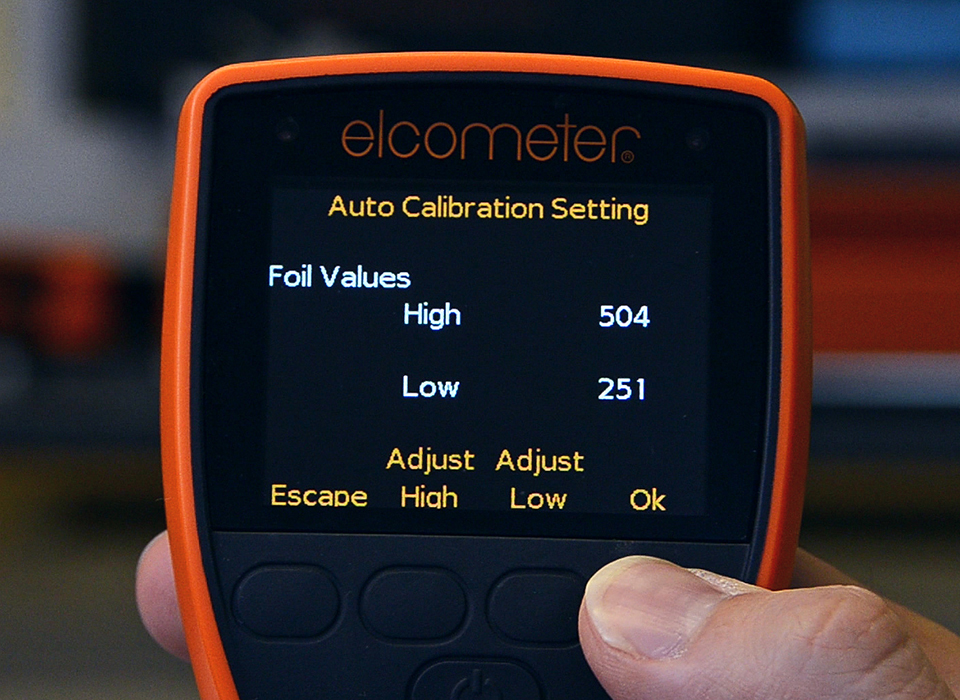

The importance of Coating Thickness Gauge Calibration

Formal quality systems, such as those described in ISO 9001, require coating thickness gauges to be properly controlled, logged and calibrated. Increasingly, users are specifying that the readings taken by thickness gauges are traceable to National Standards.

In order to test the accuracy of a particular paint thickness gauge, it is important to have traceable coating thickness standards.

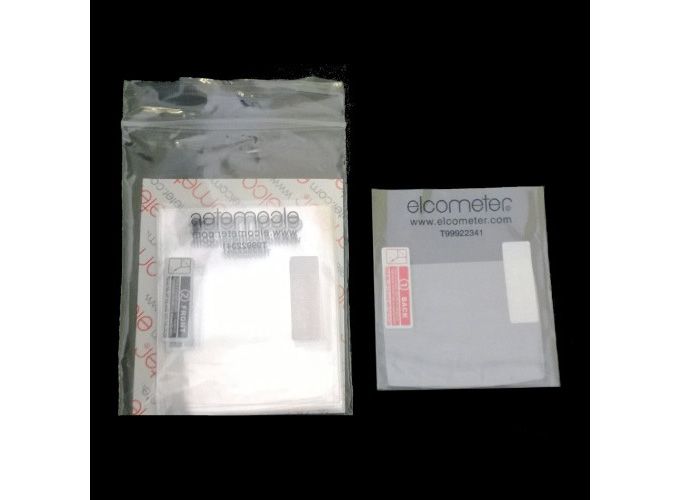

Elcometer offer a comprehensive range of certified foils together with zero test plates to ensure the accuracy of the coating thickness gauge.

Get the best performance from the Elcometer 456 Coating Thickness Gauge and make the best use of the paint gage’s ±1% accuracy by calibrating the mil gage to suit the application. This video will guide you through a range of calibration options for both the integral and the separate models.

*The Elcometer 456 is supplied with a 1 year warranty against manufacturing defects. The warranty can be extended free of charge to 2 years within 60 days of purchase

-

- Product Features

-

Product FeaturesElcometer 456 Coating Thickness Gauge - Separate

Product Feature Standard Optional Model B Model S Model T Fast, accurate reading rate; 70+ readings per minute Repeatable & reproducible measurements Easy to use menu structure; in 30+ languages Tough, impact, waterproof & dust resistant; equivalent to IP64 Bright colour screen; with permanent backlight Scratch & solvent resistant display; 2.4” (6cm) TFT Large positive feedback buttons USB power supply; via PC Test certificate 2 year gauge warranty1 Automatic rotating display; 0°, 90°, 180° & 270° Ambient light sensor; with adjustable auto brightness Emergency Light Tap awake from sleep Gauge software updates2; via ElcoMaster® software Data Output USB; to computer Bluetooth®; to computer, Android™ & iOS3 devices On Screen Statistics Number of readings; η Mean (average); x, Standard deviation; σ Highest reading; Hi, Lowest reading; Lo, Coefficient of variation; CV%, Elcometer index value4; EIV Nominal dry film thickness; NDFT IMO PSPC; %>NDFT, %>90 <NDFT, 90:10 pass/fail High & low limits; definable audible & visual alarms Number of readings above high limit; Number of readings below low limit; Live reading trend graph; in Batch Mode ElcoMaster® software & USB cable Replaceable screen protectors Protective case Plastic transit case Separate models; with automatic probe recognition Probe type; Ferrous (F), Non-Ferrous (N), Dual (FNF) F, N, FNFF, N, FNFF, N, FNFMeasurement Range 0-31mm (0-1,220mils)0-31mm (0-1,220mils)0-31mm (0-1,220mils)On screen calibration instructions; in 30+ languages Multiple calibration methods Factory; resets to the factory calibration 2-point; for smooth and rough surfaces 1-point; zero calibration Zero offset; for calibration according to ISO19840 Predefined calibration & measurement methods ISO, SSPC PA2, Swedish, Australian Automatic calibration; for rapid calibration Calibration memory type; gauge (g) or gauge & batch (gb) ggbgbNumber of batches; with unique calibrations 12,500Calibration memories: 3 programmable memories Measurement outside calibration warning Calibration lock; with optional PIN Code Unlock Delete last reading Gauge memory; number of readings Last 51,500150,000Individual batch calibrations; sent to PC via ElcoMaster® software Limits; user definable audible & visual pass/fail warnings Gauge (g) or gauge & batch specific (gb) limits ggbDate & time stamp Review, clear & delete batches Batch types; normal, counted average, IMO PSPC Navsea Mode Batch review graph Copy batches and calibration settings Alpha-numeric batch names; user definable on the gauge Scan & Auto Repeat Modes; with Scan Probe connected Fixed Batch Size Mode; with batch linking Product Feature Standard Optional Fast, accurate reading rate; 70+ readings per minute ModelB ModelS ModelT Repeatable & reproducible measurements ModelB ModelS ModelT Easy to use menu structure; in 30+ languages ModelB ModelS ModelT Tough, impact, waterproof & dust resistant; equivalent to IP64 ModelB ModelS ModelT Bright colour screen; with permanent backlight ModelB ModelS ModelT Scratch & solvent resistant display; 2.4” (6cm) TFT ModelB ModelS ModelT Large positive feedback buttons ModelB ModelS ModelT USB power supply; via PC ModelB ModelS ModelT Test certificate ModelB ModelS ModelT 2 year gauge warranty1 ModelB ModelS ModelT Automatic rotating display; 0°, 90°, 180° & 270° ModelB ModelS ModelT Ambient light sensor; with adjustable auto brightness ModelB ModelS ModelT Emergency Light ModelB ModelS ModelT Tap awake from sleep ModelB ModelS ModelT Gauge software updates2; via ElcoMaster® software ModelB ModelS ModelT Data Output ModelB ModelS ModelT USB; to computer ModelB ModelS ModelT Bluetooth®; to computer, Android™ & iOS3 devices ModelB ModelS ModelT On Screen Statistics ModelB ModelS ModelT Number of readings; η Mean (average); x, Standard deviation; σ Highest reading; Hi, Lowest reading; Lo, Coefficient of variation; CV%, Elcometer index value4; EIV ModelB ModelS ModelT Nominal dry film thickness; NDFT ModelB ModelS ModelT IMO PSPC; %>NDFT, %>90 <NDFT, 90:10 pass/fail ModelB ModelS ModelT High & low limits; definable audible & visual alarms ModelB ModelS ModelT Number of readings above high limit; ModelB ModelS ModelT Number of readings below low limit; ModelB ModelS ModelT Live reading trend graph; in Batch Mode ModelB ModelS ModelT ElcoMaster® software & USB cable ModelB ModelS ModelT Replaceable screen protectors ModelB ModelS ModelT Protective case ModelB ModelS ModelT Plastic transit case ModelB ModelS ModelT Separate models; with automatic probe recognition ModelB ModelS ModelT Probe type; Ferrous (F), Non-Ferrous (N), Dual (FNF) ModelB F, N, FNFModelS F, N, FNFModelT F, N, FNFMeasurement Range ModelB 0-31mm (0-1,220mils)ModelS 0-31mm (0-1,220mils)ModelT 0-31mm (0-1,220mils)On screen calibration instructions; in 30+ languages ModelB ModelS ModelT Multiple calibration methods ModelB ModelS ModelT Factory; resets to the factory calibration ModelB ModelS ModelT 2-point; for smooth and rough surfaces ModelB ModelS ModelT 1-point; zero calibration ModelB ModelS ModelT Zero offset; for calibration according to ISO19840 ModelB ModelS ModelT Predefined calibration & measurement methods ModelB ModelS ModelT ISO, SSPC PA2, Swedish, Australian ModelB ModelS ModelT Automatic calibration; for rapid calibration ModelB ModelS ModelT Calibration memory type; gauge (g) or gauge & batch (gb) ModelB gModelS gbModelT gbNumber of batches; with unique calibrations ModelB ModelS 1ModelT 2,500Calibration memories: 3 programmable memories ModelB ModelS ModelT Measurement outside calibration warning ModelB ModelS ModelT Calibration lock; with optional PIN Code Unlock ModelB ModelS ModelT Delete last reading ModelB ModelS ModelT Gauge memory; number of readings ModelB Last 5ModelS 1,500ModelT 150,000Individual batch calibrations; sent to PC via ElcoMaster® software ModelB ModelS ModelT Limits; user definable audible & visual pass/fail warnings ModelB ModelS ModelT Gauge (g) or gauge & batch specific (gb) limits ModelB ModelS gModelT gbDate & time stamp ModelB ModelS ModelT Review, clear & delete batches ModelB ModelS ModelT Batch types; normal, counted average, IMO PSPC ModelB ModelS ModelT Navsea Mode ModelB ModelS ModelT Batch review graph ModelB ModelS ModelT Copy batches and calibration settings ModelB ModelS ModelT Alpha-numeric batch names; user definable on the gauge ModelB ModelS ModelT Scan & Auto Repeat Modes; with Scan Probe connected ModelB ModelS ModelT Fixed Batch Size Mode; with batch linking ModelB ModelS ModelT 1 The Elcometer 456 is supplied with a 1 year warranty against manufacturing defects. The warranty can be extended free of charge to 2 years within 60 days of purchase.

2 Internet connection required

3 Visit www.elcometer.com/sdk to find out how to integrate Elcometer’s MFi certified products to your App.

4 Elcometer Index Values are used in the automotive industry to assess a coating’s overall quality; USA Patent Number US7606671B2

-

- Technical Information

-

Technical SpecificationElcometer 456 Coating Thickness Gauge - Separate

Model Model B Model S Model T Certificate Elcometer 456 Ferrous Separate A456CFBS A456CFSS A456CFTS

Elcometer 456 Non-Ferrous Separate Coating Thickness Gauge A456CNBS A456CNSS A456CNTS

Elcometer 456 Dual FNF Separate Coating Thickness Gauge A456CFNFBS A456CFNFSS A456CFNFTS

Display Information 2.4” (6cm) QVGA colour TFT display, 320 x 240 pixels Battery Type 2 x AA batteries, rechargeable batteries can also be used Battery Life approximately 24 hours of continuous use at 1 reading per second* Gauge Dimensions (h x w x d) 14.1 x 7.30 x 3.70cm (5.55 x 2.87 x 1.46”) Gauge Weight (including batteries supplied) 161g (5.68oz) Operating Temperature -10 to 50°C (14 to 122°F) Packing List Elcometer 456 gauge, wrist harness, transit case (T), protective case (B, S, T), 1 x screen protector (S, T), 2 x AA batteries, operating instructions, USB cable (S, T), ElcoMaster® software (S, T) Model Model B / S / T Certificate Elcometer 456 Ferrous Separate A456CFBS

A456CFSS

A456CFTS

Elcometer 456 Non-Ferrous Separate Coating Thickness Gauge A456CNBS

A456CNSS

A456CNTS

Elcometer 456 Dual FNF Separate Coating Thickness Gauge A456CFNFBS

A456CFNFSS

A456CFNFTS

Display Information 2.4” (6cm) QVGA colour TFT display, 320 x 240 pixels Battery Type 2 x AA batteries, rechargeable batteries can also be used Battery Life approximately 24 hours of continuous use at 1 reading per second* Gauge Dimensions (h x w x d) 14.1 x 7.30 x 3.70cm (5.55 x 2.87 x 1.46”) Gauge Weight (including batteries supplied) 161g (5.68oz) Operating Temperature -10 to 50°C (14 to 122°F) Packing List Elcometer 456 gauge, wrist harness, transit case (T), protective case (B, S, T), 1 x screen protector (S, T), 2 x AA batteries, operating instructions, USB cable (S, T), ElcoMaster® software (S, T) * Using default settings & lithium batteries, alkaline or rechargeable batteries may differ

● Certificate supplied as standard

-

- Standards

-

StandardsElcometer 456 Coating Thickness Gauge - Separate

AS 2331.1.4, AS 3894.3-B, AS/NZS 1580.108.1, ASTM B 244, ASTM B 499, ASTM D 1186-B, ASTM D 1400, ASTM D 7091, ASTM E 376, ASTM G 12, BS 3900-C5-6B, BS 3900-C5-6A, BS 5411-11, BS 5411-3, BS 5599, DIN 50981, DIN 50984, ECCA T1, EN 13523-1, IMO MSC.215(82), IMO MSC.244 (83), ISO 1461, ISO 19840, ISO 2063, ISO 2178, ISO 2360, ISO 2808-6A, ISO 2808-6B, ISO 2808-7C, ISO 2808-7D, ISO 2808-12, JIS K 5600-1-7, NF T30-124, SS 184159, SSPC PA 2, US Navy PPI 63101-000, US Navy NSI 009-32

Standards in grey have been superseded but are still recognised in some industries.

-

- Downloads

-

Downloads

-

Elcometer 456 Coating Thickness Gauge Multi-Lingual Instruction Manual

-

Elcometer 456 Coating Thickness Gauge Datasheet

-

Elcometer 456 Model B Coating Thickness Gauge CE Declaration of Conformity

-

Elcometer 456 Model B Coating Thickness Gauge UKCA Declaration of Conformity

-

Elcometer 456 Model S & T Coating Thickness Gauge CE Declaration of Conformity

-

Elcometer 456 Model S & T Coating Thickness Gauge UKCA Declaration of Conformity

- Part Numbers

-

Part NumbersElcometer 456 Coating Thickness Gauge - SeparateNo data found!!

-

Elcometer 456 Model B Ferrous Separate Coating Thickness Gauge

Elcometer 456 Model B Ferrous Separate Coating Thickness Gauge- Model: Model B

- Substrate Option: Ferrous (F)

- Probe Option: Supplied Separately

- Part Number : A456CFBS

-

Elcometer 456 Model T Ferrous Separate Coating Thickness Gauge

Elcometer 456 Model T Ferrous Separate Coating Thickness Gauge- Model: Model T

- Substrate Option: Ferrous (F)

- Probe Option: Supplied Separately

- Part Number : A456CFTS

-

Elcometer 456 Model S Ferrous Separate Coating Thickness Gauge

Elcometer 456 Model S Ferrous Separate Coating Thickness Gauge- Model: Model S

- Substrate Option: Ferrous (F)

- Probe Option: Supplied Separately

- Part Number : A456CFSS

-

Elcometer 456 Model B Non-Ferrous Separate Coating Thickness Gauge

Elcometer 456 Model B Non-Ferrous Separate Coating Thickness Gauge- Model: Model B

- Substrate Option: Non-Ferrous (N)

- Probe Option: Supplied Separately

- Part Number : A456CNBS

-

Elcometer 456 Model S Non-Ferrous Separate Coating Thickness Gauge

Elcometer 456 Model S Non-Ferrous Separate Coating Thickness Gauge- Model: Model S

- Substrate Option: Non-Ferrous (N)

- Probe Option: Supplied Separately

- Part Number : A456CNSS

-

Elcometer 456 Model T Non-Ferrous Separate Coating Thickness Gauge

Elcometer 456 Model T Non-Ferrous Separate Coating Thickness Gauge- Model: Model T

- Substrate Option: Non-Ferrous (N)

- Probe Option: Supplied Separately

- Part Number : A456CNTS

-

Elcometer 456 Model B Dual FNF Separate Coating Thickness Gauge

Elcometer 456 Model B Dual FNF Separate Coating Thickness Gauge- Model: Model B

- Substrate Option: Dual (FNF)

- Probe Option: Supplied Separately

- Part Number : A456CFNFBS

-

Elcometer 456 Model S Dual FNF Separate Coating Thickness Gauge

Elcometer 456 Model S Dual FNF Separate Coating Thickness Gauge- Model: Model S

- Substrate Option: Dual (FNF)

- Probe Option: Supplied Separately

- Part Number : A456CFNFSS

-

Elcometer 456 Model T Dual FNF Separate Coating Thickness Gauge

Elcometer 456 Model T Dual FNF Separate Coating Thickness Gauge- Model: Model T

- Substrate Option: Dual (FNF)

- Probe Option: Supplied Separately

- Part Number : A456CFNFTS

- Accessories

-

AccessoriesElcometer 456 Coating Thickness Gauge - Separate

ElcoMaster®

It’s not all about taking readings, it’s what you do with them that counts - save up to 30% of your working week by producing professional reports in seconds with ElcoMaster® Software.

Part Number: Elcometer-Zero-Test-Plates

Part Number: Elcometer-Zero-Test-Plates Part Number: Probe-Placement-JIG

Part Number: Probe-Placement-JIG Part Number: T99921325

Part Number: T99921325 Part Number: T99922341

Part Number: T99922341 Part Number: T45622371

Part Number: T45622371 Part Number: Elcometer-990-Individual-Precision-Foils

Part Number: Elcometer-990-Individual-Precision-Foils Part Number: Elcometer-990-Calibration-Foils-Sets

Part Number: Elcometer-990-Calibration-Foils-Sets Part Number: T9997766-

Part Number: T9997766- Part Number: T99913225

Part Number: T99913225 Part Number: T9997381-

Part Number: T9997381- Part Number: T99913133

Part Number: T99913133 Part Number: T456C23956

Part Number: T456C23956 Part Number: T99925387

Part Number: T99925387

Welcome to Elcometer.tv

Your ultimate training channel

- Home

- Coatings Inspection

- Coatings Inspection Division

- Dry Film Thickness

- Digital Coating Thickness Gauges

- Elcometer 456 Coating Thickness Gauge - Separate

Elcometer 456 Coating Thickness Gauge - Separate

- Protective Coatings

- Industrial Finishing

The Elcometer 456 Coating Thickness Gauge is available with a wide range of separate interchangeable probes; providing greater coating thickness measurement flexibility on metal substrates.

Fast Coating Thickness Measurements

The Elcometer 456 Coating Thickness Gauge enhances efficiency by providing 70+ dry film thickness readings per minute (140+ per minute when using a scan probe). The Elcometer 456 mil gage has multiple calibration memories and alpha numeric batch identification.

An Accurate Coating Thickness Gauge

Accuracy is key when taking coating thickness measurements, that's why the Elcometer 456 paint meter is designed to measure dry film thickness on smooth, rough, thin and curved surfaces to ±1% in accordance with National & International Standards.

Powerful Memory & Data Output

The Elcometer 456 Coating Thickness Gauge stores up to 150,000 readings in 2,500 batches and has the ability to measure up to 31mm (1,220mils) of coating on metal substrates. Its USB and Bluetooth® data output make it compatible with ElcoMaster® Data Management Software for fast and accurate coating inspection reporting.

Summary

Elcometer 456 Coating Thickness Gauge - Separate

The Elcometer 456 Coating Thickness Gauge is available in three different models. Each coating thickness gauge provides the user with increasing functionality - from the entry level Elcometer 456 Paint Thickness Gauge Model B, to the top of the range Elcometer 456 Film Thickness Gauge Model T.

Separate coating thickness gauge models, with their wide range of probes, provide even greater dry film thickness measurement flexibility.

Compatible with ElcoMaster® software and ElcoMaster® Mobile App, individual coating thickness measurements can be transferred via USB or Bluetooth® to PC or a mobile device for analysis and instant report generation.

For more information on What is a Coating Thickness Gauge, click here

Elcometer 456 Integral Coating Thickness Gauge

Integral dry film thickness gauges are ideal for single handed operation as the wide footprint of the Bigfoot™ internal probe provides greater stability during coating thickness measurement

ElcoMaster® Data Management Software

Inspectors can spend up to 30% of their working week producing reports. ElcoMaster® Software saves time and money by producing professional bespoke reports - even when out on site.

Downloads-

Elcometer 456 Coating Thickness Gauge Multi-Lingual Instruction Manual

-

Elcometer 456 Coating Thickness Gauge Datasheet

-

Elcometer 456 Model B Coating Thickness Gauge CE Declaration of Conformity

-

Elcometer 456 Model B Coating Thickness Gauge UKCA Declaration of Conformity

-

Elcometer 456 Model S & T Coating Thickness Gauge CE Declaration of Conformity

-

Elcometer 456 Model S & T Coating Thickness Gauge UKCA Declaration of Conformity

Key Features

Elcometer 456 Coating Thickness Gauge - Separate

An easy to use Coating Thickness Gauge

Designed with large buttons and a colour screen, the Elcometer 456 Coating Thickness Gauge allows easy measurements thanks to its enhanced usability. The paint gauge features an LCD screen with auto rotate and is factory calibrated with high and low reading limit indicators in multiple languages.

Reliablilty You Can Trust

Designed to last, this heavy duty, impact resistant Coating Thickness Gauge is supplied with fully traceable test certificates and an Elcometer 2 year gauge warranty*.

The importance of Coating Thickness Gauge Calibration

Formal quality systems, such as those described in ISO 9001, require coating thickness gauges to be properly controlled, logged and calibrated. Increasingly, users are specifying that the readings taken by thickness gauges are traceable to National Standards.

In order to test the accuracy of a particular paint thickness gauge, it is important to have traceable coating thickness standards.

Elcometer offer a comprehensive range of certified foils together with zero test plates to ensure the accuracy of the coating thickness gauge.

Get the best performance from the Elcometer 456 Coating Thickness Gauge and make the best use of the paint gage’s ±1% accuracy by calibrating the mil gage to suit the application. This video will guide you through a range of calibration options for both the integral and the separate models.

*The Elcometer 456 is supplied with a 1 year warranty against manufacturing defects. The warranty can be extended free of charge to 2 years within 60 days of purchase

Product FeaturesElcometer 456 Coating Thickness Gauge - SeparateProduct Feature Standard Optional Model B Model S Model T Fast, accurate reading rate; 70+ readings per minute Repeatable & reproducible measurements Easy to use menu structure; in 30+ languages Tough, impact, waterproof & dust resistant; equivalent to IP64 Bright colour screen; with permanent backlight Scratch & solvent resistant display; 2.4” (6cm) TFT Large positive feedback buttons USB power supply; via PC Test certificate 2 year gauge warranty1 Automatic rotating display; 0°, 90°, 180° & 270° Ambient light sensor; with adjustable auto brightness Emergency Light Tap awake from sleep Gauge software updates2; via ElcoMaster® software Data Output USB; to computer Bluetooth®; to computer, Android™ & iOS3 devices On Screen Statistics Number of readings; η Mean (average); x, Standard deviation; σ Highest reading; Hi, Lowest reading; Lo, Coefficient of variation; CV%, Elcometer index value4; EIV Nominal dry film thickness; NDFT IMO PSPC; %>NDFT, %>90 <NDFT, 90:10 pass/fail High & low limits; definable audible & visual alarms Number of readings above high limit; Number of readings below low limit; Live reading trend graph; in Batch Mode ElcoMaster® software & USB cable Replaceable screen protectors Protective case Plastic transit case Separate models; with automatic probe recognition Probe type; Ferrous (F), Non-Ferrous (N), Dual (FNF) F, N, FNFF, N, FNFF, N, FNFMeasurement Range 0-31mm (0-1,220mils)0-31mm (0-1,220mils)0-31mm (0-1,220mils)On screen calibration instructions; in 30+ languages Multiple calibration methods Factory; resets to the factory calibration 2-point; for smooth and rough surfaces 1-point; zero calibration Zero offset; for calibration according to ISO19840 Predefined calibration & measurement methods ISO, SSPC PA2, Swedish, Australian Automatic calibration; for rapid calibration Calibration memory type; gauge (g) or gauge & batch (gb) ggbgbNumber of batches; with unique calibrations 12,500Calibration memories: 3 programmable memories Measurement outside calibration warning Calibration lock; with optional PIN Code Unlock Delete last reading Gauge memory; number of readings Last 51,500150,000Individual batch calibrations; sent to PC via ElcoMaster® software Limits; user definable audible & visual pass/fail warnings Gauge (g) or gauge & batch specific (gb) limits ggbDate & time stamp Review, clear & delete batches Batch types; normal, counted average, IMO PSPC Navsea Mode Batch review graph Copy batches and calibration settings Alpha-numeric batch names; user definable on the gauge Scan & Auto Repeat Modes; with Scan Probe connected Fixed Batch Size Mode; with batch linking Product Feature Standard Optional Fast, accurate reading rate; 70+ readings per minute ModelB ModelS ModelT Repeatable & reproducible measurements ModelB ModelS ModelT Easy to use menu structure; in 30+ languages ModelB ModelS ModelT Tough, impact, waterproof & dust resistant; equivalent to IP64 ModelB ModelS ModelT Bright colour screen; with permanent backlight ModelB ModelS ModelT Scratch & solvent resistant display; 2.4” (6cm) TFT ModelB ModelS ModelT Large positive feedback buttons ModelB ModelS ModelT USB power supply; via PC ModelB ModelS ModelT Test certificate ModelB ModelS ModelT 2 year gauge warranty1 ModelB ModelS ModelT Automatic rotating display; 0°, 90°, 180° & 270° ModelB ModelS ModelT Ambient light sensor; with adjustable auto brightness ModelB ModelS ModelT Emergency Light ModelB ModelS ModelT Tap awake from sleep ModelB ModelS ModelT Gauge software updates2; via ElcoMaster® software ModelB ModelS ModelT Data Output ModelB ModelS ModelT USB; to computer ModelB ModelS ModelT Bluetooth®; to computer, Android™ & iOS3 devices ModelB ModelS ModelT On Screen Statistics ModelB ModelS ModelT Number of readings; η Mean (average); x, Standard deviation; σ Highest reading; Hi, Lowest reading; Lo, Coefficient of variation; CV%, Elcometer index value4; EIV ModelB ModelS ModelT Nominal dry film thickness; NDFT ModelB ModelS ModelT IMO PSPC; %>NDFT, %>90 <NDFT, 90:10 pass/fail ModelB ModelS ModelT High & low limits; definable audible & visual alarms ModelB ModelS ModelT Number of readings above high limit; ModelB ModelS ModelT Number of readings below low limit; ModelB ModelS ModelT Live reading trend graph; in Batch Mode ModelB ModelS ModelT ElcoMaster® software & USB cable ModelB ModelS ModelT Replaceable screen protectors ModelB ModelS ModelT Protective case ModelB ModelS ModelT Plastic transit case ModelB ModelS ModelT Separate models; with automatic probe recognition ModelB ModelS ModelT Probe type; Ferrous (F), Non-Ferrous (N), Dual (FNF) ModelB F, N, FNFModelS F, N, FNFModelT F, N, FNFMeasurement Range ModelB 0-31mm (0-1,220mils)ModelS 0-31mm (0-1,220mils)ModelT 0-31mm (0-1,220mils)On screen calibration instructions; in 30+ languages ModelB ModelS ModelT Multiple calibration methods ModelB ModelS ModelT Factory; resets to the factory calibration ModelB ModelS ModelT 2-point; for smooth and rough surfaces ModelB ModelS ModelT 1-point; zero calibration ModelB ModelS ModelT Zero offset; for calibration according to ISO19840 ModelB ModelS ModelT Predefined calibration & measurement methods ModelB ModelS ModelT ISO, SSPC PA2, Swedish, Australian ModelB ModelS ModelT Automatic calibration; for rapid calibration ModelB ModelS ModelT Calibration memory type; gauge (g) or gauge & batch (gb) ModelB gModelS gbModelT gbNumber of batches; with unique calibrations ModelB ModelS 1ModelT 2,500Calibration memories: 3 programmable memories ModelB ModelS ModelT Measurement outside calibration warning ModelB ModelS ModelT Calibration lock; with optional PIN Code Unlock ModelB ModelS ModelT Delete last reading ModelB ModelS ModelT Gauge memory; number of readings ModelB Last 5ModelS 1,500ModelT 150,000Individual batch calibrations; sent to PC via ElcoMaster® software ModelB ModelS ModelT Limits; user definable audible & visual pass/fail warnings ModelB ModelS ModelT Gauge (g) or gauge & batch specific (gb) limits ModelB ModelS gModelT gbDate & time stamp ModelB ModelS ModelT Review, clear & delete batches ModelB ModelS ModelT Batch types; normal, counted average, IMO PSPC ModelB ModelS ModelT Navsea Mode ModelB ModelS ModelT Batch review graph ModelB ModelS ModelT Copy batches and calibration settings ModelB ModelS ModelT Alpha-numeric batch names; user definable on the gauge ModelB ModelS ModelT Scan & Auto Repeat Modes; with Scan Probe connected ModelB ModelS ModelT Fixed Batch Size Mode; with batch linking ModelB ModelS ModelT 1 The Elcometer 456 is supplied with a 1 year warranty against manufacturing defects. The warranty can be extended free of charge to 2 years within 60 days of purchase.

2 Internet connection required

3 Visit www.elcometer.com/sdk to find out how to integrate Elcometer’s MFi certified products to your App.

4 Elcometer Index Values are used in the automotive industry to assess a coating’s overall quality; USA Patent Number US7606671B2

Technical SpecificationElcometer 456 Coating Thickness Gauge - SeparateModel Model B Model S Model T Certificate Elcometer 456 Ferrous Separate A456CFBS A456CFSS A456CFTS

Elcometer 456 Non-Ferrous Separate Coating Thickness Gauge A456CNBS A456CNSS A456CNTS

Elcometer 456 Dual FNF Separate Coating Thickness Gauge A456CFNFBS A456CFNFSS A456CFNFTS

Display Information 2.4” (6cm) QVGA colour TFT display, 320 x 240 pixels Battery Type 2 x AA batteries, rechargeable batteries can also be used Battery Life approximately 24 hours of continuous use at 1 reading per second* Gauge Dimensions (h x w x d) 14.1 x 7.30 x 3.70cm (5.55 x 2.87 x 1.46”) Gauge Weight (including batteries supplied) 161g (5.68oz) Operating Temperature -10 to 50°C (14 to 122°F) Packing List Elcometer 456 gauge, wrist harness, transit case (T), protective case (B, S, T), 1 x screen protector (S, T), 2 x AA batteries, operating instructions, USB cable (S, T), ElcoMaster® software (S, T) Model Model B / S / T Certificate Elcometer 456 Ferrous Separate A456CFBS

A456CFSS

A456CFTS

Elcometer 456 Non-Ferrous Separate Coating Thickness Gauge A456CNBS

A456CNSS

A456CNTS

Elcometer 456 Dual FNF Separate Coating Thickness Gauge A456CFNFBS

A456CFNFSS

A456CFNFTS

Display Information 2.4” (6cm) QVGA colour TFT display, 320 x 240 pixels Battery Type 2 x AA batteries, rechargeable batteries can also be used Battery Life approximately 24 hours of continuous use at 1 reading per second* Gauge Dimensions (h x w x d) 14.1 x 7.30 x 3.70cm (5.55 x 2.87 x 1.46”) Gauge Weight (including batteries supplied) 161g (5.68oz) Operating Temperature -10 to 50°C (14 to 122°F) Packing List Elcometer 456 gauge, wrist harness, transit case (T), protective case (B, S, T), 1 x screen protector (S, T), 2 x AA batteries, operating instructions, USB cable (S, T), ElcoMaster® software (S, T) * Using default settings & lithium batteries, alkaline or rechargeable batteries may differ

● Certificate supplied as standardStandardsElcometer 456 Coating Thickness Gauge - SeparateAS 2331.1.4, AS 3894.3-B, AS/NZS 1580.108.1, ASTM B 244, ASTM B 499, ASTM D 1186-B, ASTM D 1400, ASTM D 7091, ASTM E 376, ASTM G 12, BS 3900-C5-6B, BS 3900-C5-6A, BS 5411-11, BS 5411-3, BS 5599, DIN 50981, DIN 50984, ECCA T1, EN 13523-1, IMO MSC.215(82), IMO MSC.244 (83), ISO 1461, ISO 19840, ISO 2063, ISO 2178, ISO 2360, ISO 2808-6A, ISO 2808-6B, ISO 2808-7C, ISO 2808-7D, ISO 2808-12, JIS K 5600-1-7, NF T30-124, SS 184159, SSPC PA 2, US Navy PPI 63101-000, US Navy NSI 009-32

Standards in grey have been superseded but are still recognised in some industries.

Part NumbersElcometer 456 Coating Thickness Gauge - SeparateNo data found!!-

Elcometer 456 Model B Ferrous Separate Coating Thickness Gauge

Elcometer 456 Model B Ferrous Separate Coating Thickness Gauge- Model: Model B

- Substrate Option: Ferrous (F)

- Probe Option: Supplied Separately

- Part Number : A456CFBS

-

Elcometer 456 Model T Ferrous Separate Coating Thickness Gauge

Elcometer 456 Model T Ferrous Separate Coating Thickness Gauge- Model: Model T

- Substrate Option: Ferrous (F)

- Probe Option: Supplied Separately

- Part Number : A456CFTS

-

Elcometer 456 Model S Ferrous Separate Coating Thickness Gauge

Elcometer 456 Model S Ferrous Separate Coating Thickness Gauge- Model: Model S

- Substrate Option: Ferrous (F)

- Probe Option: Supplied Separately

- Part Number : A456CFSS

-

Elcometer 456 Model B Non-Ferrous Separate Coating Thickness Gauge

Elcometer 456 Model B Non-Ferrous Separate Coating Thickness Gauge- Model: Model B

- Substrate Option: Non-Ferrous (N)

- Probe Option: Supplied Separately

- Part Number : A456CNBS

-

Elcometer 456 Model S Non-Ferrous Separate Coating Thickness Gauge

Elcometer 456 Model S Non-Ferrous Separate Coating Thickness Gauge- Model: Model S

- Substrate Option: Non-Ferrous (N)

- Probe Option: Supplied Separately

- Part Number : A456CNSS

-

Elcometer 456 Model T Non-Ferrous Separate Coating Thickness Gauge

Elcometer 456 Model T Non-Ferrous Separate Coating Thickness Gauge- Model: Model T

- Substrate Option: Non-Ferrous (N)

- Probe Option: Supplied Separately

- Part Number : A456CNTS

-

Elcometer 456 Model B Dual FNF Separate Coating Thickness Gauge

Elcometer 456 Model B Dual FNF Separate Coating Thickness Gauge- Model: Model B

- Substrate Option: Dual (FNF)

- Probe Option: Supplied Separately

- Part Number : A456CFNFBS

-

Elcometer 456 Model S Dual FNF Separate Coating Thickness Gauge

Elcometer 456 Model S Dual FNF Separate Coating Thickness Gauge- Model: Model S

- Substrate Option: Dual (FNF)

- Probe Option: Supplied Separately

- Part Number : A456CFNFSS

-

Elcometer 456 Model T Dual FNF Separate Coating Thickness Gauge

Elcometer 456 Model T Dual FNF Separate Coating Thickness Gauge- Model: Model T

- Substrate Option: Dual (FNF)

- Probe Option: Supplied Separately

- Part Number : A456CFNFTS

Welcome to Elcometer.tv

Your ultimate training channelAccessoriesElcometer 456 Coating Thickness Gauge - SeparateElcoMaster®

It’s not all about taking readings, it’s what you do with them that counts - save up to 30% of your working week by producing professional reports in seconds with ElcoMaster® Software.

Part Number: Elcometer-Zero-Test-Plates

Part Number: Elcometer-Zero-Test-Plates Part Number: Probe-Placement-JIG

Part Number: Probe-Placement-JIG Part Number: T99921325

Part Number: T99921325 Part Number: T99922341

Part Number: T99922341 Part Number: T45622371

Part Number: T45622371 Part Number: Elcometer-990-Individual-Precision-Foils

Part Number: Elcometer-990-Individual-Precision-Foils Part Number: Elcometer-990-Calibration-Foils-Sets

Part Number: Elcometer-990-Calibration-Foils-Sets Part Number: T9997766-

Part Number: T9997766- Part Number: T99913225

Part Number: T99913225 Part Number: T9997381-

Part Number: T9997381- Part Number: T99913133

Part Number: T99913133 Part Number: T456C23956

Part Number: T456C23956 Part Number: T99925387

Part Number: T99925387

-

-