Elcometer 1540 Cross Cut Adhesion Tester

- Protective Coatings

- Industrial Finishing

The Elcometer 1540 Cross Cut Adhesion Tester is a simple instrument for quickly determining the coating adhesion of a large variety of paints up to 50µm (2 mils) thickness.

- Summary

-

Summary

-

Made from steel, this cross hatch gauge has 11 tapered teeth with 1mm spacing. Two sets of lines are cut at right angles to obtain a pattern of 100 squares.

-

- Key Features

-

Key Features

Elcometer 1540 Cross Cut Adhesion Tester

Classification of Cross Hatch Test Results

Surface

Typical description of result

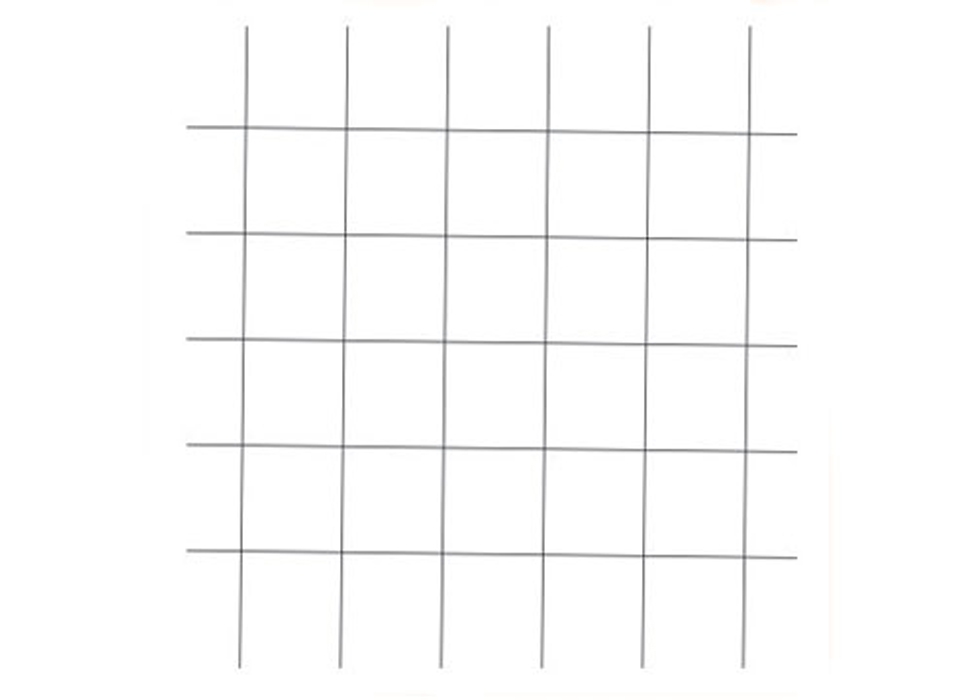

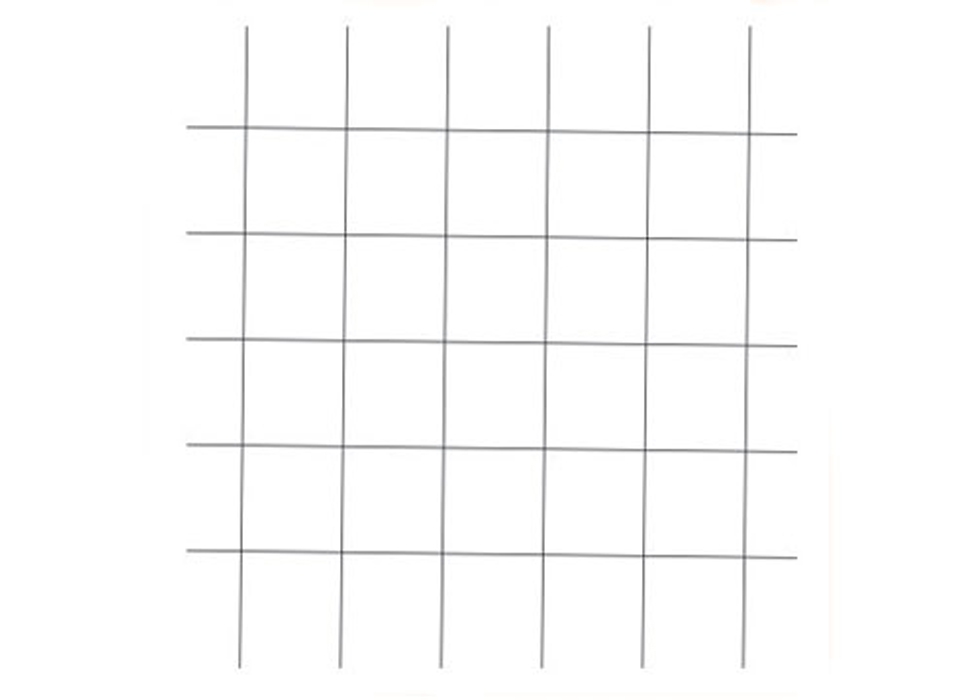

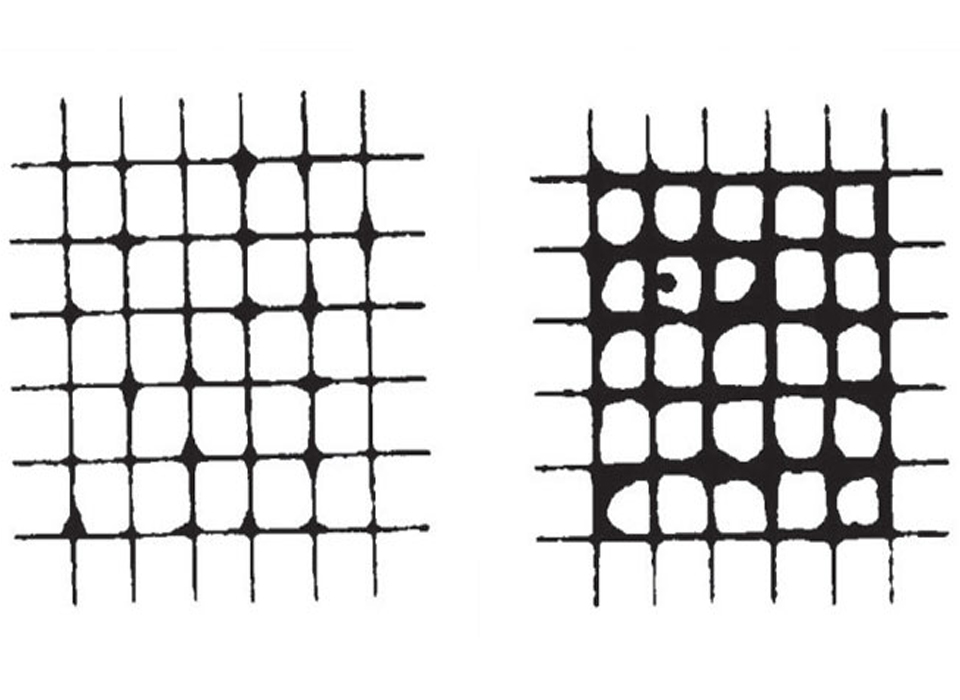

The edges of the cuts are completely smooth, none of the squares of the lattice is detached.

ISO: 0

ASTM: 5B

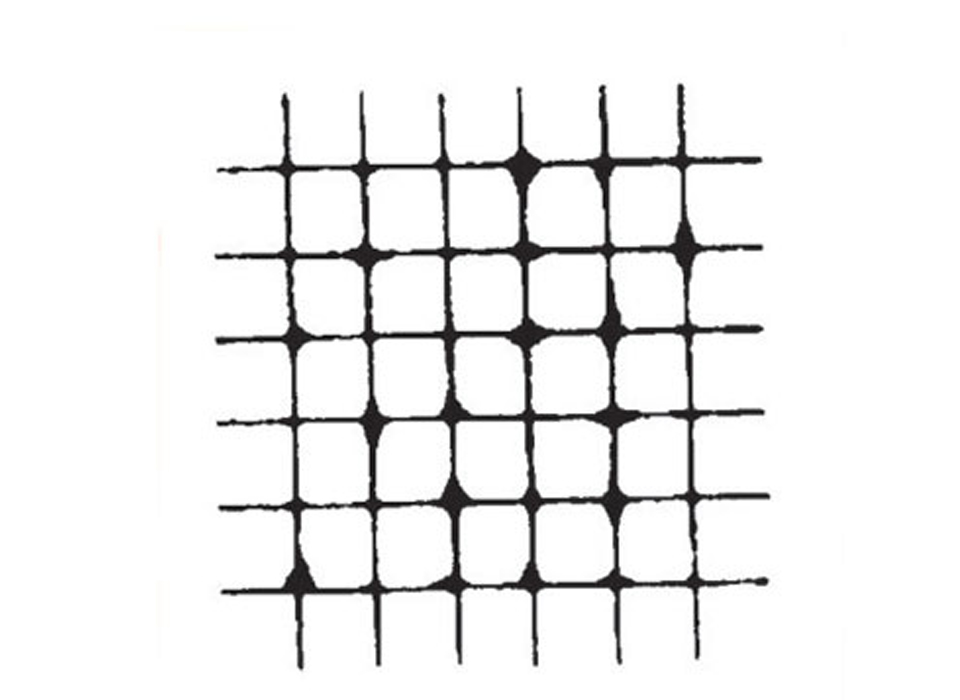

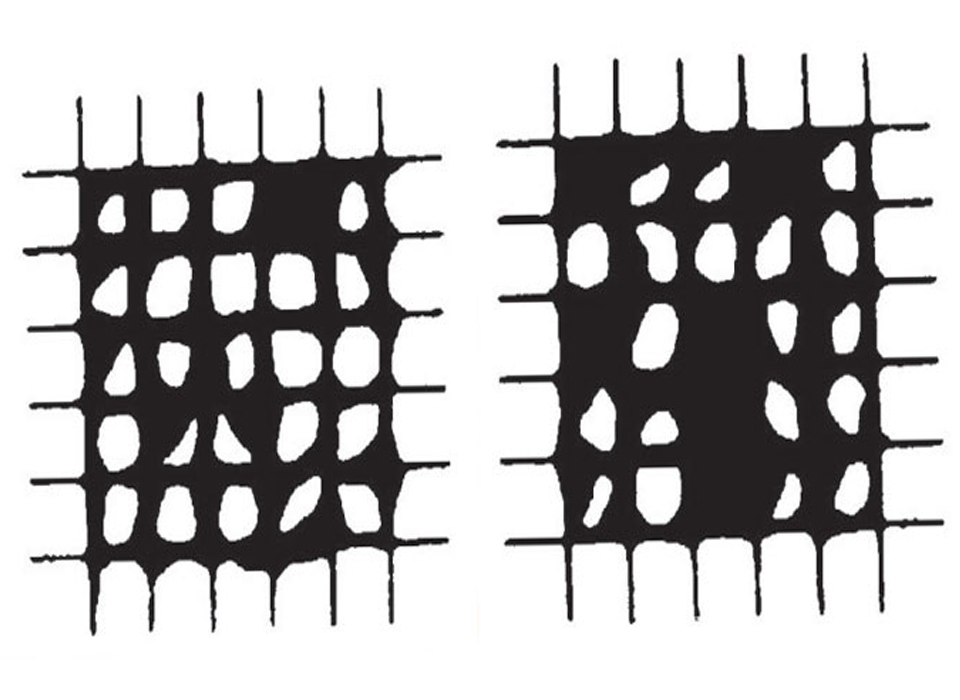

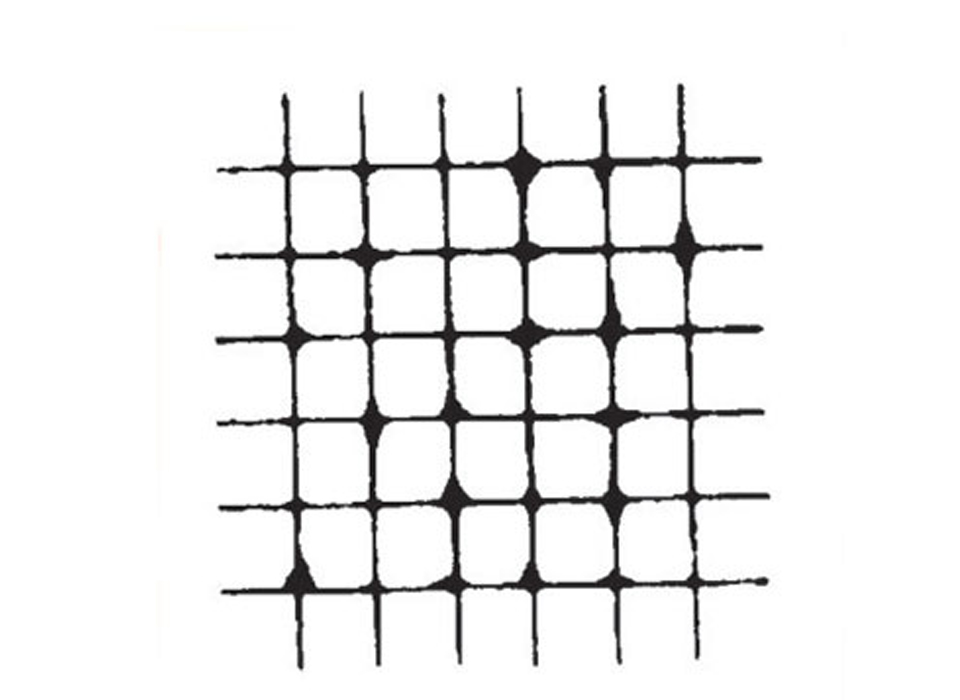

Detachment of small flakes of the coating at the intersections of the cuts. A cross cut area not significantly greater than 5%, is affected.

ISO: 1

ASTM: 4B

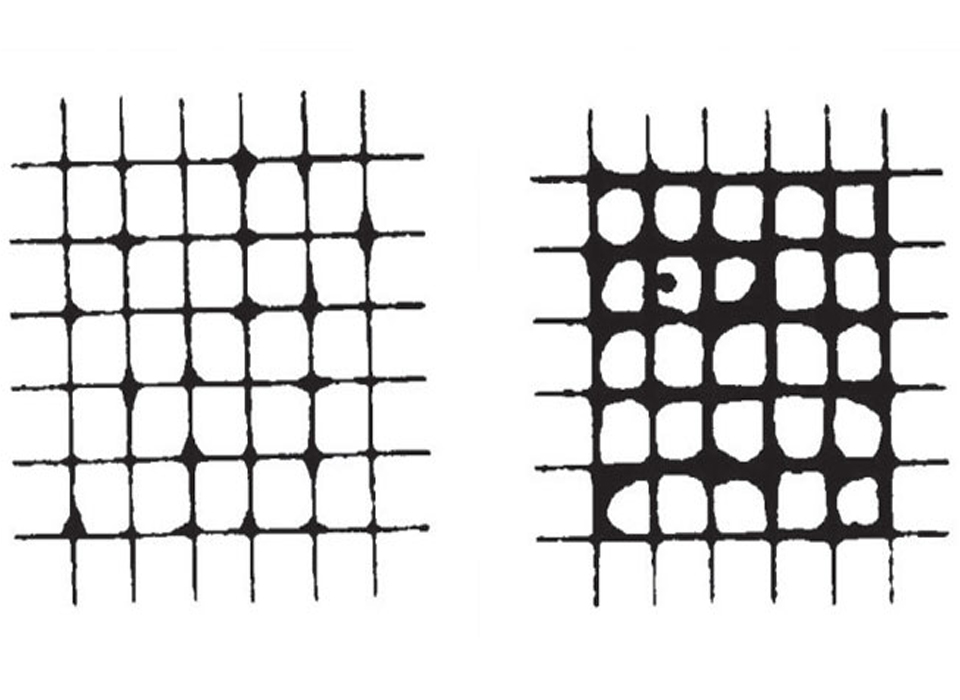

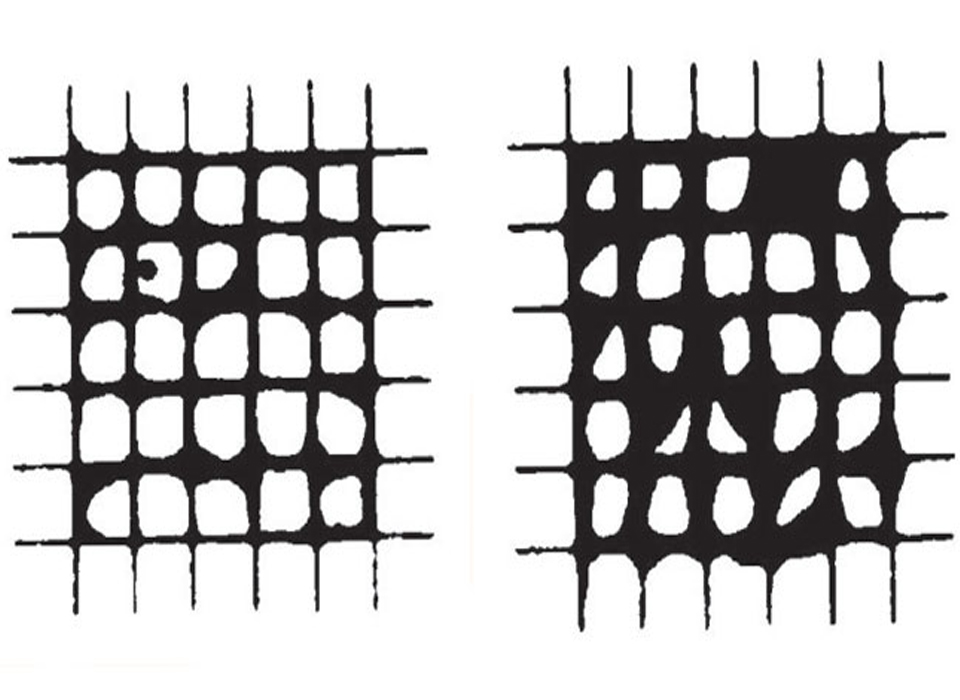

The coating has flaked along the edges and/or at the intersections of the cuts. A cross cut area significantly greater than 5%, but not significantly greater than 15%, is affected.ISO: 2

ASTM: 3B

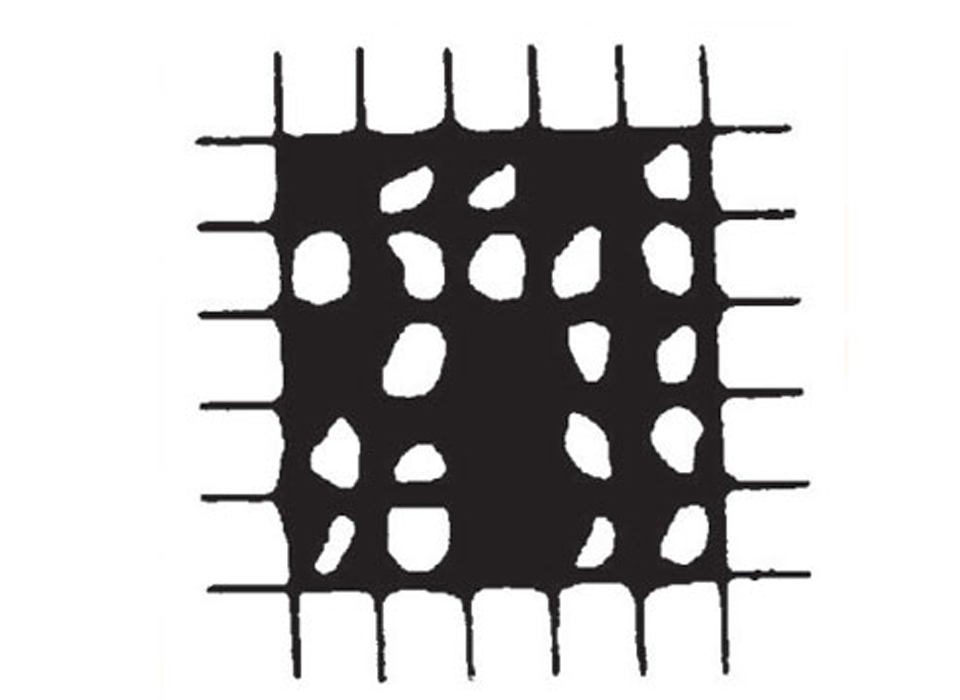

The coating has flaked along the edges of the cuts partly or wholly in large ribbons, and/or it has flaked partly or wholly on different parts of the squares. A cross cut area significantly greater than 15%, but not significantly greater than 35%, is affected.

ISO: 3

ASTM: 2B

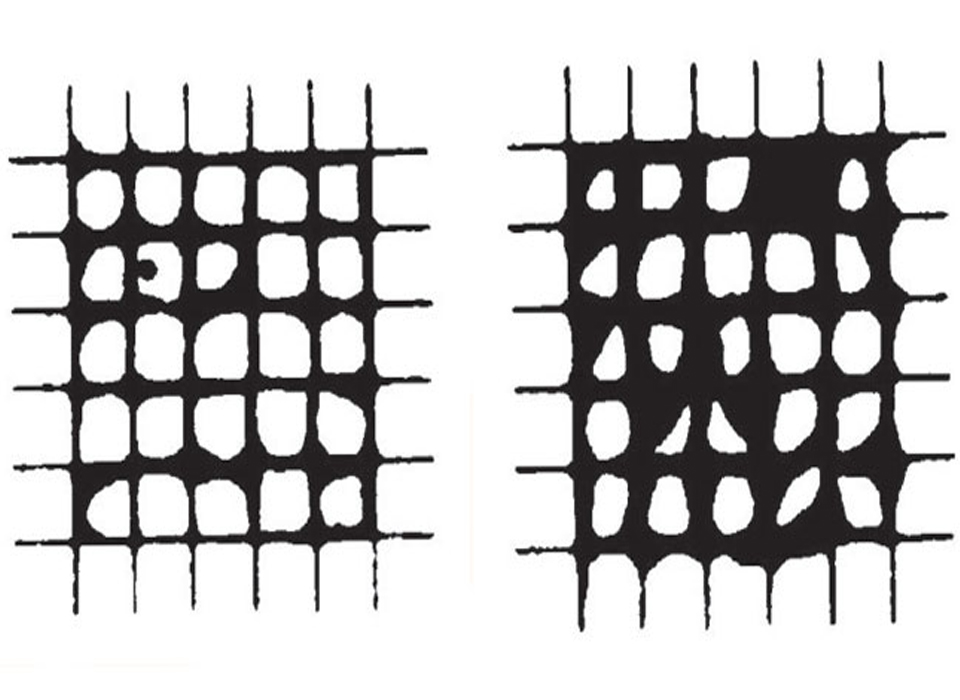

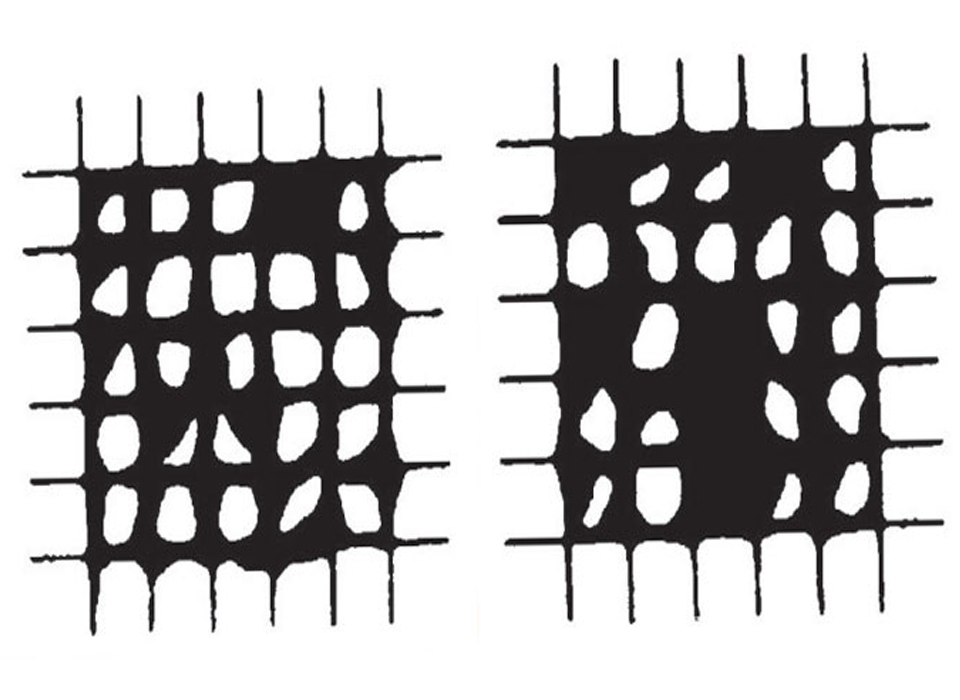

The coating has flaked along the edges of the cuts in large ribbons and/or some squares have detached partly or wholly. A cross cut area significantly greater than 35%, but not significantly greater than 65%, is affected.

ISO: 4

ASTM: 1B

Any degree of flaking that cannot be classified even by classification 4 (1B).

ISO: 5

ASTM: 0B

Images and descriptions based on information published in ISO2409 and ASTM D 3559-B

-

- Technical Information

-

Technical SpecificationElcometer 1540 Cross Cut Adhesion Tester

Part Number Description Certificate K0001540M001 Elcometer 1540 Cross Cut Tester (11 x 1mm)  ○ Optional Calibration Certificate available.

○ Optional Calibration Certificate available.- Downloads

-

Downloads

- Part Numbers

-

Part NumbersElcometer 1540 Cross Cut Adhesion TesterNo data found!!

-

Elcometer 1540 Cross Cut Adhesion Tester

Elcometer 1540 Cross Cut Adhesion Tester- Part Number : K0001540M001

-

Elcometer 1540 Cross Cut Adhesion Tester

Elcometer 1540 Cross Cut Adhesion Tester- Part Number : K0001540M001C

-

- Home

- Coatings Inspection

- Coatings Inspection Division

- Adhesion Testers

- Elcometer 1540 Cross Cut Adhesion Tester

Elcometer 1540 Cross Cut Adhesion Tester

- Protective Coatings

- Industrial Finishing

The Elcometer 1540 Cross Cut Adhesion Tester is a simple instrument for quickly determining the coating adhesion of a large variety of paints up to 50µm (2 mils) thickness.

Summary

Elcometer 1540 Cross Cut Adhesion Tester

Made from steel, this cross hatch gauge has 11 tapered teeth with 1mm spacing. Two sets of lines are cut at right angles to obtain a pattern of 100 squares.

Key Features

Elcometer 1540 Cross Cut Adhesion Tester

Classification of Cross Hatch Test Results

Surface

Typical description of result

The edges of the cuts are completely smooth, none of the squares of the lattice is detached.

ISO: 0

ASTM: 5B

Detachment of small flakes of the coating at the intersections of the cuts. A cross cut area not significantly greater than 5%, is affected.

ISO: 1

ASTM: 4B

The coating has flaked along the edges and/or at the intersections of the cuts. A cross cut area significantly greater than 5%, but not significantly greater than 15%, is affected.ISO: 2

ASTM: 3B

The coating has flaked along the edges of the cuts partly or wholly in large ribbons, and/or it has flaked partly or wholly on different parts of the squares. A cross cut area significantly greater than 15%, but not significantly greater than 35%, is affected.

ISO: 3

ASTM: 2B

The coating has flaked along the edges of the cuts in large ribbons and/or some squares have detached partly or wholly. A cross cut area significantly greater than 35%, but not significantly greater than 65%, is affected.

ISO: 4

ASTM: 1B

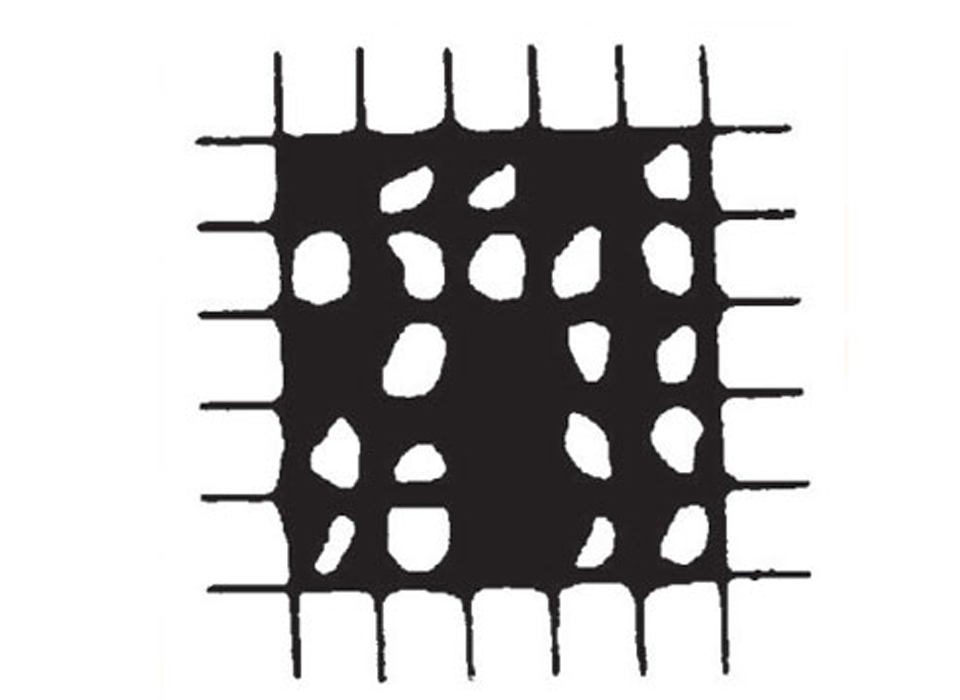

Any degree of flaking that cannot be classified even by classification 4 (1B).

ISO: 5

ASTM: 0B

Images and descriptions based on information published in ISO2409 and ASTM D 3559-B

Technical SpecificationElcometer 1540 Cross Cut Adhesion TesterPart Number Description Certificate K0001540M001 Elcometer 1540 Cross Cut Tester (11 x 1mm)  ○ Optional Calibration Certificate available.Part NumbersElcometer 1540 Cross Cut Adhesion TesterNo data found!!

○ Optional Calibration Certificate available.Part NumbersElcometer 1540 Cross Cut Adhesion TesterNo data found!!-

Elcometer 1540 Cross Cut Adhesion Tester

Elcometer 1540 Cross Cut Adhesion Tester- Part Number : K0001540M001

-

Elcometer 1540 Cross Cut Adhesion Tester

Elcometer 1540 Cross Cut Adhesion Tester- Part Number : K0001540M001C

- Part Numbers

- Downloads

-