Types of Flaws

Once the coating has been applied to the surface following the required specification, it is not the end of the inspection process. Throughout the life of the coating continuous checks need to be carried out to monitor the integrity of the protective coating from its initial application.

When a coating is applied to a surface, there are a number of problems or situations that can occur which, although not necessarily obvious at the time, can cause problems later on in the life of the coating. Premature corrosion of a substrate is usually due to a failure of the coating. One cause is the presence of flaws in the finished coating. The main types of flaws are:

Runs & Sags

Coatings move under gravity leaving a thin dry film.

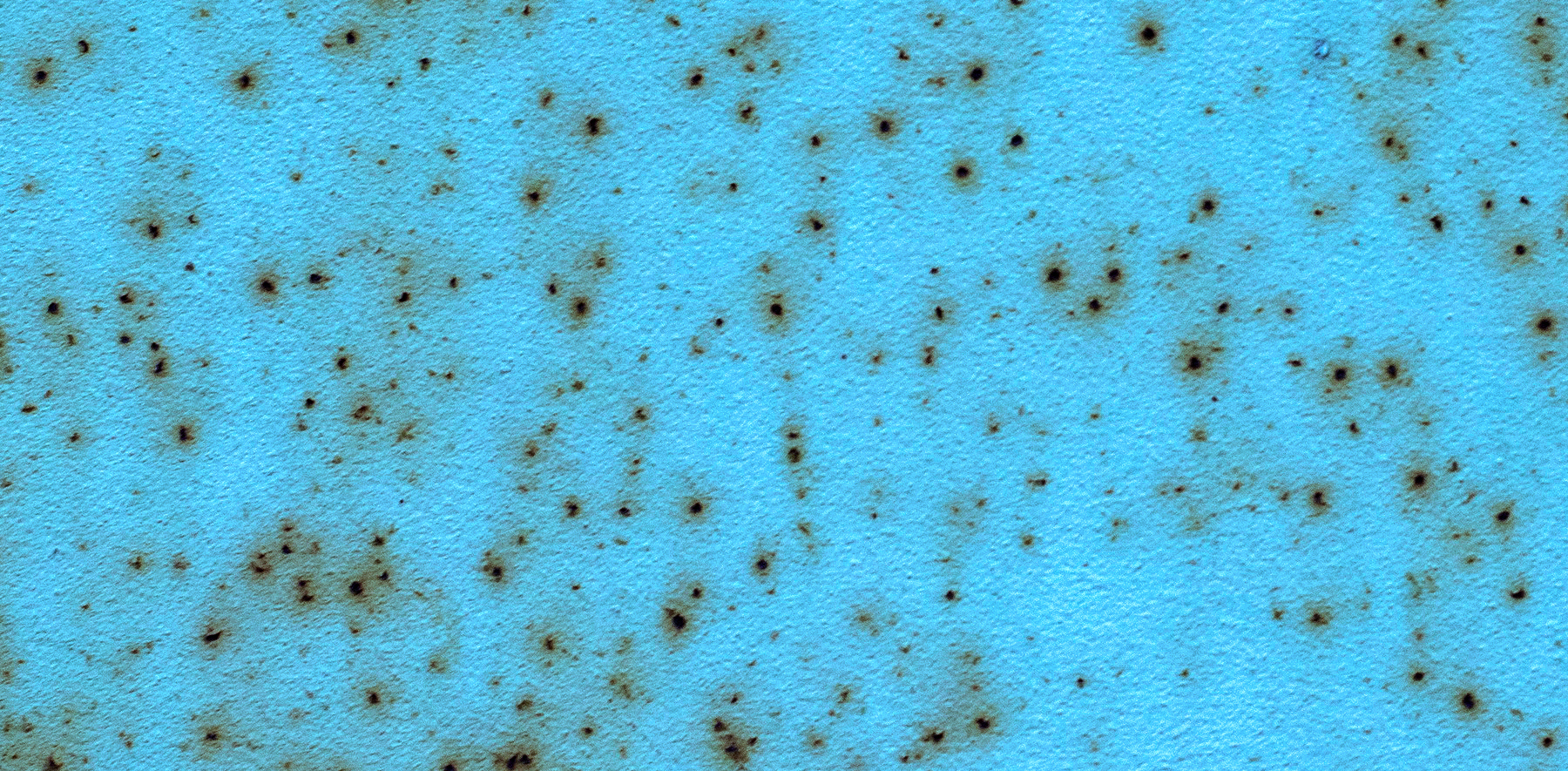

Cissing

Cissing is when a coating does not re-flow to cover the voids generated by the air bubbles being released from the surface of a coating.

This creates small, crater like holes or indentations in the paint surface, varying in size from pinholes up to 1cm (0.40in) in diameter. Usually, the larger craters occur individually, whilst the smaller ones are often found in small densely packed clusters. Small impurities are often visible in the centre of the crater.

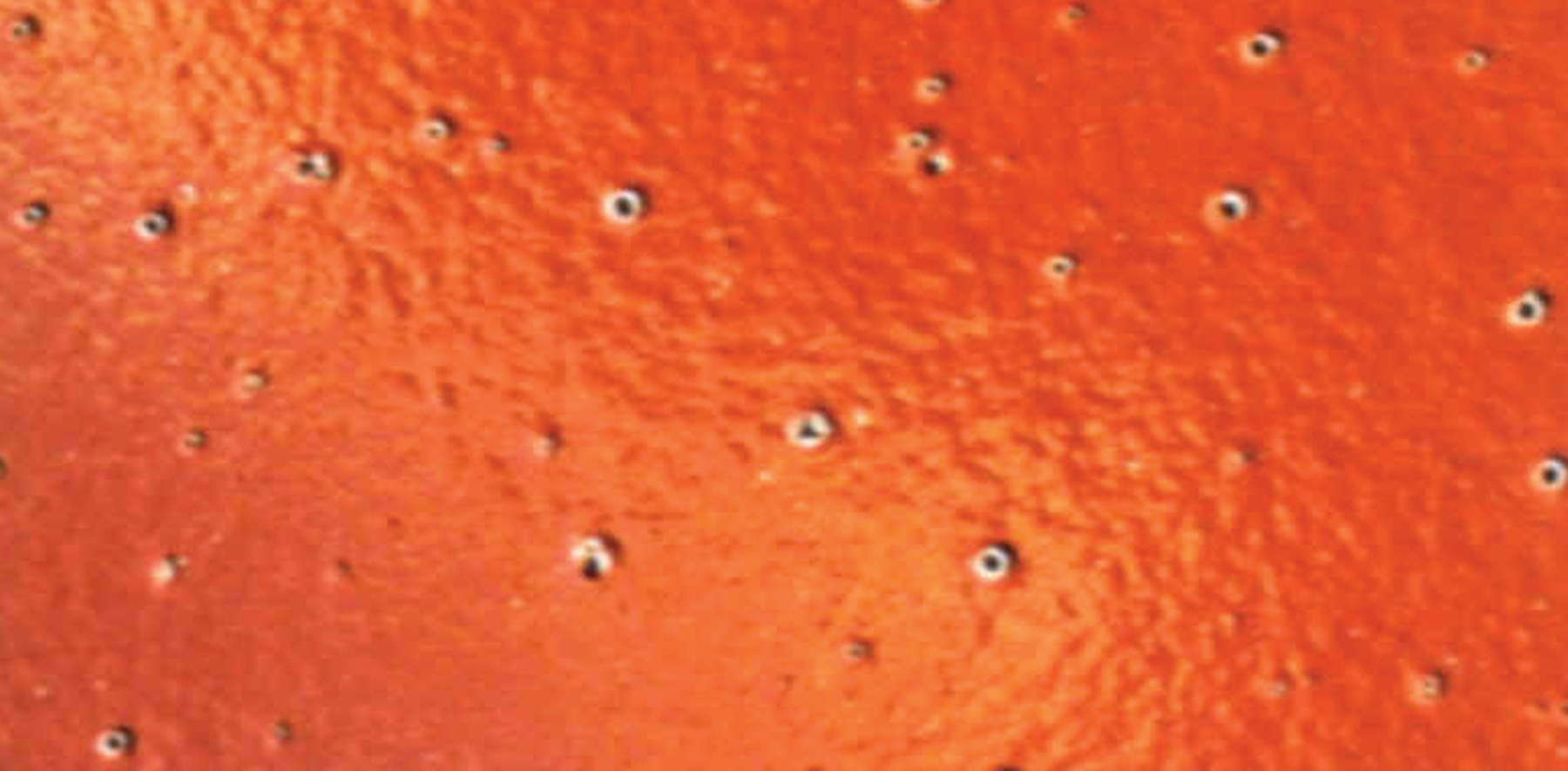

Cratering

If the substrate is wet or the coating has poor flow characteristics, voids are created in the coating.

The defect is mainly caused by mixing contamination with the wet film. Some binders have a greater tendency to cratering, on encountering contamination they form craters. This is thought to be because the surface tension is affected. Cratering occurs before the coating is completely cured. Cratering areas are potential sites for coating failures.

Undercoating

Undercoating is where the coating is thinner than specified or where the coating flows away from edges/corners of a substrate/weld due to surface tension effects. In the worst case, the substrate remains uncoated. Insufficient coating over a rough surface profile may also leave the peaks of the profile exposed.

Pinholes

Pinholes are caused by air entrapment, created by vigorous mixing of the coating, which is then released from the surface, or by the entrapment of particulates (dust, sand etc.) which do not stay in place.

Overcoating

If too much coating is applied, as it cures, internal stresses of the coating can cause it to crack.